Ultrafiltration System

Get Price Quote

1 Set (MOQ)

Ultrafiltration System

Get Price Quote

Best Deals from Ultrafiltration System

Ultra Filtration Water Purification System

125,000 Per Piece

1 Piece (MOQ)

Ultrafiltration Membrane System

Get Price Quote

1 Piece (MOQ)

Ultrafiltration Water Treatment Plant Installation Service

Get Price Quote

Ultra Filtration and Nano Filtration System

Get Price Quote

1 Piece (MOQ)

Ultra Filtration Plant

50,000 Per

Ultra Fine Filtration System

Get Price Quote

PROCESS – For fine filtration and conditioning of product water and to make the Product water crystal clear, shining and fresh.

Ultrafiltration Water Treatment Plant

150,000 - 500,000 Per Piece

1 Piece (MOQ)

Ultrafiltration is a low-pressure membrane process used to separate bacteria, viruses, and high molecular weight compounds colloidal and particulate matters from a feed stream. Ultrafiltration has larger pores and high permeability with less osmotic effects that allows ultrafiltration to operate at relatively lower pressure than nanofiltration and reverse osmosis and is therefore it is least costly to operate. Ultrafiltration is widely used in industry as pretreatment for other forms of purification such as ion exchange and reverse osmosis, gelatin and protein concentration in the pharmaceutical industry, sugar clarification in the food and beverage industry, cheese and whey concentration, production of ultra pure water, clarification of juice, downstream processing, membrane bioreactors, treatment of bleach plant effluents, and recovery of lignin compounds in the pulp and paper industry. Ultrafiltration can be used to reject virus, bacteria, pyrogens, endotoxins, and particulates but not ionic species.

Ultra Filtration Plant

145,500 Per Unit

1 Unit (MOQ)

Ultrafiltration Plant

250,000 - 250,500 Per piece

1 Piece (MOQ)

Ultrafiltration is a low-pressure membrane process used to separate bacteria, viruses, and high molecular weight compounds colloidal and particulate matters from a feed stream. Ultrafiltration has larger pores and high permeability with less osmotic effects that allows ultrafiltration to operate at relatively lower pressure than nanofiltration and reverse osmosis and is therefore it is least costly to operate.Ultrafiltration is widely used in industry as pre-treatment for other forms of purification such as ion exchange and reverse osmosis, gelatin and protein concentration in the pharmaceutical industry, sugar clarification in the food and beverage industry, cheese and whey concentration, production of ultra pure water, clarification of juice, downstream processing, membrane bioreactors, treatment of bleach plant effluents, and recovery of lignin compounds in the pulp and paper industry. Ultrafiltration can be used to reject virus, bacteria, pyrogens, endotoxins, and particulates but not ionic species.Hollow fiber configuration is widely used in the ultrafiltration processes. The benefit of this construction is that it allows for backwashing of the membrane when the filtrate or product flow rate has decreased due to accumulation of material on the membrane. The ultrafiltration membrane is capable of removing colloidal materials, fine suspensions, bacteria, virus, suspended material and large dissolved molecular weight organic materials.Advantages : Product SDI typically less than 1 Removal of virus, and bacteria Removal of microbiological matter Removal of colloidal matter Colloidal Silica Reduction Improvement of downstream Reverse Osmosis (RO) performance Consistently treated water quality irrespective of changes in feed water quality Applications : Pre-treatment to RO system Purification of surface and well water for potable applications Filtration of industrial water Membrane Bio-Reactor Wastewater recycle and reuse

Ultrafiltration Plant

Get Price Quote

1 Plant (MOQ)

We are noted as trustworthy manufacturers of Ultrafiltration Plants in India and providing ultimate water filtration services to our esteemed clientele. Our offered Ultra Filtration Systems are designed for treatment of Total suspended solids, Turbidity, SDI, Silica, Bacteria, Virus, pseudomonas and Endotoxins removal in order to provide complete water filtration solutions to our valued customers. We are offering remarkable custom-made Ultrafiltration Water systems that are used in both pretreatment and post treatment of water. Our offered Ultrafiltration Plants are manufactured with state of art facility under the supervision of experts. Quality control is our priority and ensures that all our offered Ultrafiltration Plants are passed laid quality checking procedures. Our offered Ultrafiltration Plants are appreciated for their efficiency, corrosion resistant, durability, easy operation and easy maintenance, thus makes us as ultimate choice as Ultrafiltration Plant manufacturer in India to our esteemed clientele. We are offering finest quality Ultrafiltration Plants at competitive prices available in the market. Millipure water systems make ULTRAFILTRATION SYSTEM is used in Pharmaceutical, Biotechnologies, Food, after ETP and STP as final treatment. UF SYSTEM can be used as pretreatment to RO plant to reduce and control Total viable counts, bacteria, pseudomonas and endotoxins. Chlorine tolerant membranes reduce bio growth. UF system in post treatment is hot water sanitizable. The equipment is designed to meet the stringents standards set by major pharmacopoeias such as USP, IP, BP and JP The plant is designed and manufactured as per cGMP and in accordance to ASME BPE requirement. All inter connecting piping is done by orbital welding with high purity argon gas and welding joints can be inspected with Boroscopy machine. Core Features & Characteristics of the system is crevices & dead leg free design, <0.4µ RA finish from inside & outside <0.8 µ RA, complete drain ability; Non– Contact MOC -304. Unit is completely piped, wired and assembled on a single skid at the factory hence reduces installation cost and startup time PLC and SCADA based system with online printing facility to achieve compliance with 21 CFR PART 11 and GAMP 5 so less human interferance and low maintenance required. Automatic Backwash and CIP ensures ease of operation. Complete set of Documentation like DQ, IQ, OQ, FAT, and SAT with certificates and also assist client to develop PQ to achieve compliance with necessary regulatory authority.

Ultrafiltration System

100,000 - 500,000 Per piece

1 Piece (MOQ)

Ultra Filtration Plant

Get Price Quote

1 Plant (MOQ)

Ultra Filtration (UF) is a type of membrane filtration. Industries such as chemical and pharmaceutical manufacturing, food and beverage processing, and waste water treatment, employ Ultra Filtration in order to recycle flow or add value to later products. Ultra Filtration is commonly abbreviated to "UF." Product Description UF's main attraction is its ability to purify, separate, and concentrate target macromolecules in continuous systems. UF does this by pressurizing the solution flow. The solvent and other dissolved components that pass through the membrane are known as permeate. The components that do not pass through are known as retentate. Depending on the Molecular Weight Cut off (MWCO) of the membrane used, macromolecules may be purified, separated, or concentrated in either fraction. Currently, the study of UF processing occurs mainly in laboratory setups[citation needed] because it is very prone to membrane fouling caused by increased solute concentration at the membrane surface (either by macromolecular adsorption to internal pore structure of membrane, or aggregation of protein deposit on surface of membrane), which leads to concentration polarization (CP)). CP is the major culprit in decreasing permeates flux. Ultra Filtration is used as a pre-treatment step in reverse osmosis processes in many Middle Eastern countries to potable drinking water, as there is little fresh water available in those areas. Benefits No need for chemicals (coagulants, flocculates, disinfectants, pH adjustment) Size-exclusion filtration as opposed to media depth filtration Good and constant quality of the treated water in terms of particle and microbial removal Process and plant compactness Simple automation Environmentally friendly What does Ultra Filtration remove? Endotoxins Plastics Proteins Silica Silt Smog Viruses

Ultrafiltration Plant

350,000 Per Pieces

1 Pieces (MOQ)

Ultra Filtration Water System

50,000 - 500,000 Per Piece

5 Piece (MOQ)

Ultra Filtration System

Get Price Quote

1 Set (MOQ)

Ultrafiltration Water Treatment Plant

45,000 Per Piece

1 Piece (MOQ)

Ultra Filtration Water Treatment Plant

300,000 - 800,000 Per Set

1 Set (MOQ)

Ultra Modern Rice Plant

Get Price Quote

1 Piece (MOQ)

Ultra Filtration System

Get Price Quote

We maintain proper schedules for the delivery of bulk or urgent consignments so as to deliver the range in set time and gain utmost customer satisfaction. We are a focused towards bringing forth exceptional array of products (Ultra Filtration System for industrial/commercial ) that are quality tested from the initial stages of manufacturing. Our quality inspectors inspect each and every element of the raw material with complete proficiency.

Ultra Filtration System

Get Price Quote

1 Piece (MOQ)

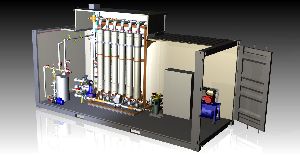

Ultrafiltration (UF) is an important purification technology used for the production of high-purity water in the many industries. When strategically combined with other purification technologies in a complete water & Wastewater system. UF membranes used to remove high molecular-weight substances, colloidal materials, silt, turbidity, organic / inorganic polymeric molecules, algae, particulate matters, suspended solids and all microorganisms from Water & Wastewater. UF Plants are designed for a variety of industrial & commercial applications requiring high quality equipment with a fast delivery and competitive price. These pre-engineered, pre-assembled and factory tested units minimize installation and startup time. With simple utility connections and easy to set up controls, the unit is ready for quick online service. The control system is an advanced microprocessor based system that is very easy to use.

Industrial Ultrafiltration (UF) Systems / Plants

Get Price Quote

We are Manufacturer, Supplier, Exporter of Industrial Ultrafiltration (UF) Systems / Plants and our setup is situated in Pune, Maharashtra, India. We are also Services Provider of above products in Mumbai, Nashik, Aurangabad, Kolhapur, Sangli, Satara, Raigad, Maharashtra, Gujrat and Karanataka, India Ultrafiltration (UF) is a highly effective method of water purification that employs a semi-permeable membrane to remove contaminants. The process relies on pressure differentials to separate suspended solids, bacteria, viruses, and macromolecules from water. The membrane in an ultrafiltration system is the core component responsible for the filtration process. It consists of a porous material that acts as a barrier, allowing water molecules to pass through while capturing larger particles and molecules. This membrane is designed to have specific pore sizes, typically ranging from 0.001 to 0.1 micrometers, effectively preventing the passage of most contaminants. Components Removed by Ultrafiltration: Suspended Solids: Particles such as sand, silt, and other sediments. Bacteria and Viruses: Microorganisms that can pose health risks. Macromolecules: Large molecules like proteins, polysaccharides, and other organic compounds

Ultrafiltration System

Get Price Quote

Ultrafiltration Plant

100,000 Per Units

1 Units (MOQ)

Ultra Filtration Plant

Get Price Quote

Features : Modular-Each Plant is One Module All Components Are of Proven Quality Excellent Workmanship Long Lasting Membranes Reliable Control Mechanism Easy Maintence Design Low Maintenance Quality Applications : Boiler Water Treatment Cooling Tower Water Treatment Process Water Drinking Water Wastewater Recycling Zero Liquid Discharge System River Water Treatment Pre-Post Treatment For RO Plant

Ultra Filtration Unit

Get Price Quote

Ultra filtration (UF) membrane removes almost all suspended matter and also dissolved organic compounds depending on their molecular mass and on the molecular mass cut-off of the membrane.

Ultra Water Filtration System

Get Price Quote

STANDARD FEATURES : FRP membrane housing TFC spiral wound membranes 8 "diameter AISI304 or AISI316 duplex stainless steel high-pressure pump ST37 epoxy painted carbon steel or AISI 304 stainless steel frame 5 micron cartridge filtration Low pressure line U-PVC PN16 The high pressure line or Duplex Stainless Steel aısı316t KEY APPLICATIONS High pressure boiler make-up for power generation, etc Pharmaceutical WFI Semiconductors manufacturing process Electro deionization Standard Features Single skid configuration PVC piping Conductivity analyzer on product Flow meter on feed, product and concentrate Cleaning connections Power rectifier for DC power source 90% to 95% recovery Nema 4 carbon steel local junction box Electro deionization Applications High Pressure Boiler Make-up for Power Generation, etc. Pharmaceutical WFI Semiconductor Manufacturing Process Other deionized water / EDI water applications

UF - Ultra Filtration Plants

Get Price Quote

Conceptualized and constructed as per industry standards, our UF - Ultra Filtration Plants are high on the counts of operational fluency, sturdy built and excellency. We offer our UF - Ultra Filtration Plants at marginal prices.

Ultra Filtration System

Get Price Quote

We are offering ultra filtration system. Ultra filtration plant is a type of membrane filtration system. The hydrostatic pressure and concentration gradients separates the fine granules present in water through a semipermeable membrane. This has been considered as the viable technology at earlier times. This is used to remove the presence of bacteria and several microorganisms. But the current advancements in production of membrane and designing module has declined the operating and capital cost of manufacturing.