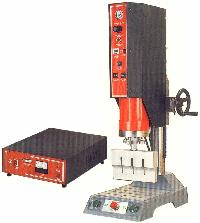

15KHZ-4200W High Power Ultrasonic Plastic Welding Machine

Get Price Quote

1 Piece (MOQ)

The 4200W Ultrasonic Plastic Welding Machine We professionally produce standard ultrasonic plastic welding machine, such as 2600 W – 3200 W plastic welding machine, 4200 W – 5600 W high power plastic welding machine and other precision welding equipment: double-head plastic welder, six-head plastic welder, hollow plastic box welding machine.Features and Function Japanese NTK transducer,imported cylinder, stronger power and more stability; Anti-backwards body and coaxial direct pressure design, make pressure exerted more evenly, higher welding precision; 4200 W high power output, suitable for larger plastic welding with good welding effect; Use high quality electrical components imported; Oscillation plate and crystal slab are imported from Taiwan; Alloy mould, sturdy and durable, not to wear; Unique design of level screw, mould is easier to debug; Limitation welding system makes the finished products not overflow; Smart structure, reasonable design and beautiful appearance.

DK.1522A Analog Ultrasonic Plastic Welding Machine

150,000 - 700,000 Per Piece

Best Deals from Ultrasonic Plastic Welding Machine

Ultrasonic Plastic Welding Machine

275,000 - 275,000 Per Piece

2 Piece (MOQ)

ultrasonic plastic welding machines

Get Price Quote

Ultrasonic Plastic Welding Machine

300,000 Per Piece

1 Piece (MOQ)

Ultrasonic Plastic Welding Machine

Get Price Quote

1 Piece(s) (MOQ)

We understand that the use of finest grade raw material brings forth high quality product line. In addition to this, we make sure that the material is sourced from the reliable places only. We are backed with highly experience packaging experts and team members; they ensure that the packaging is done with utmost proficiency and keeping in mind the globally accepted norms.

Computerized Multi Function Ultrasonic Plastic Welding Machinee

Get Price Quote

We are instrumental in offering the exceptional assortment of product that are deigned and manufactured only after complete examination of the raw materials and inputs used. We have hired a team of professionals who hold immense knowledge of packaging. They make use of premium packaging material so as to make damage free deliveries. Applications : Toys - Remote car & Boat, Plastic doll, Toy gun, Water gun, TV Game, Phone etc. Household - Washer balance ring, Computer, TV Shell, Remote unit, Steam iron. Electronic - Cassette case, Video Case, Calculator, Disc. Electrical Industry - Connector, Transformer, Relay Automobile Industry - Head light, Tail light, Brake light, Lunch Box, Rearview, Oil filter Food Industry - Thermos-bottle, Thermos cup, Food container. Stationery - Pencil case, PP file, Staple, Ink bottle, Pen stand. Other - Christmas decoration ornament, hair decoration ornament, Surgery Mask. Characteristics : Micro Computer Control System - Precision position Four different Nests Memory - Efficient function Auto Trouble Checking - Trouble Display and Alarm System Horn Frequency Checking - Check the Normal Horn Frequency Moveable Electric Control Box.

Ultrasonic Plastic Welding Machine

135,000 Per Piece

1 Piece(s) (MOQ)

Semi Automatic Ultrasonic Plastic Welding Machine

280,000 Per Set

1 Set(s) (MOQ)

We are supplier and exporter of this product.

Ultrasonic Plastic Welding Machine

Get Price Quote

At the initial stages of using raw material for the production, our dedicated quality staff makes certain that the inputs used are of premium quality. Thus, our offered range is highly appreciated for the quality. We offer a wide range of excellent quality products that are designed and developed under the vigil eyes of quality examiners.

Ultrasonic Plastic Welding Machine

200,000 - 230,000 Per piece

1 piece (MOQ)

Ultrasonic Plastic Welding Machine

Get Price Quote

Ultrasonic plastic welding machine, We Manufacture Ultrasonic Plastic Welding Equipments like • Bench type welders • Floor type welders • Ultrasonic hand guns • Manual hand press • Multihead and special purpose machines Principle: ultrasonic welding systems are based on friction principles. High frequencyn vibrations generally 20khz vibrations are given to 02 thermoplastic independent jobs. The vibrations are range is 40 microns to 140 microns. The pressure is applied along eiht vibrations which will make friction. This will led to melding of thermoplastic which further led to joining of plastic parts.

Ultrasonic Plastic Welding Machine

180,000 Per piece

1 Unit (MOQ)

An ultrasonic plastic welding machine is a specialized industrial tool designed to bond thermoplastic materials using high-frequency ultrasonic vibrations. This technique is widely used in various industries where precise, strong, and clean joints are required for plastic components, without the need for adhesives, screws, or other mechanical fasteners. Ultrasonic welding is known for its speed, efficiency, and the high-quality results it produces, making it a popular choice for manufacturing delicate and high-performance plastic parts. How It Works: The process of ultrasonic welding involves the following steps: Ultrasonic Vibrations: The machine generates ultrasonic waves (high-frequency sound waves typically above 20 kHz) using a transducer, which converts electrical energy into mechanical vibrations. Application of Vibrations: These ultrasonic vibrations are directed into the plastic parts that need to be welded. The vibrations create frictional heat at the interface of the materials, causing them to melt. Fusion: The heat generated by the ultrasonic vibrations causes the plastic at the joint area to soften and fuse together. The pressure from the welding machine ensures a solid and strong bond once the materials cool down. Cooling: After the welding process, the parts are held in place until the joint cools and solidifies, completing the bonding process. Key Features of Ultrasonic Plastic Welding Machines: Fast and Precise: The ultrasonic welding process is incredibly fast, often taking just a few seconds to complete, making it ideal for high-volume manufacturing. No Need for Adhesives: Ultrasonic welding eliminates the need for adhesives, which can be costly, messy, and potentially harmful in certain applications. It also reduces the risk of contamination. Clean and Strong Joints: The process creates very clean, strong, and durable joints without leaving visible marks or seams on the plastic, ensuring the finished product has a professional appearance. Minimal Heat Application: Unlike other welding methods, ultrasonic welding generates localized heat only at the interface of the materials being joined, which helps to preserve the integrity of surrounding areas and prevents warping. Low Energy Consumption: Ultrasonic welding uses significantly less energy compared to traditional thermal welding or adhesive bonding techniques, making it more energy-efficient. Versatility: The machine can be used for a wide range of thermoplastic materials, including polypropylene, polyethylene, PVC, ABS, and more. It's often used in industries such as automotive, electronics, medical devices, packaging, and consumer goods.

Automatic Ultrasonic Plastic Welding Machine

Get Price Quote

Ultrasonic Plastic Welding Machine

Get Price Quote

We are remarkable entity, engaged in offering high quality Ultrasonic Welding Machine that is used for welding purpose. The offered welding machine is designed by our adroit professionals from the finest quality components and ultra-modern technology in sync with industry quality norms. In order to maintain quality, this welding machine is straightly tested on different quality parameters. Clients can avail this welding machine from us at nominal prices. Features: Easy to operate Rugged construction High performance Other Details: Insert Embedding a metal component (such as a screw insert) in a performed hole in a thermoplastic part. High strength, reduced molding cycles and rapid installation with no stress build-up are some of the advantages Riveting: It is an assembly method which uses the controlled melting and reforming of a plastic stud to capture or lock another component usually of a different material Specifications:

Automatic Ultrasonic Welding Machine

Get Price Quote

1 Piece (MOQ)

Ultrasonic Welding Innovation : GO ROBO MECHATRONICS is a picneer in the development of ultrasonic welding machines, offering solutions that excel in joining thermoplastics with utmost precision. From medical devices ta consumer electronics, our ultrasonic welding technolagy sets a new standard for speed, cleanliness, and reliability. Customized Selutions : Recognizing the unique requiremsnts of sach industry, we pravide tailor-made welding solutions. Our team of engineers collaborates clossly with clients to understand their spacific needs, snsuring that cur machines not only meset but exceed expectations. Quality Assurance: Quality is at the heart of everything we do. Our manufacturing processes adhaere to the highest industry standards, and each welding machine undergoes rigorous testing to guarantee optimal performance, durability, and safety. Innovation and Sustainability: As a forward-thinking company, we are committed to sustainable practices and continucus innovation. Our R&D department is a hub of creativity, constantly exploring new technologies and methodologies to push the boundaries of what is possible in the world of welding. Conclusion: GO ROBO MECHATRONICS is not just a manufacturer; we are architeclts of progress, shaping the future of welding technology. With a relentless commitment to quality, innovation, and customer satisfaction, we invite you to join us on a joumsy where precision mests fusion, and excellence is not just a goal but a standard.

Ultrasonic Plastic Welding Machine

50,000 Per Piece

Sibas Ultrasonics offers Ultrasonic Plastic Welding Machine that helps manufacturing industries to meet their applications on plastic welding technology. .

Ultrasonic Plastic welder with Rotary Table

Get Price Quote

This machine is specially developed by AXESS for whom their production rate is very high but they wants to save labor and time.This machine’s rotary system is very robust combination of mechanical Index System, Motor and reducing gear box.Machine can be designed with desired station and desired wattage Ultrasonic system as per customer requirement. Key features: * Variable speed* Auto ejection* Choice of station 4, 8 or 16* Stroke length 75mm or can be customize (25mm~100mm) ultrasonic system as per requirement.

ultrasonic plastic welding machines

Get Price Quote

Ultrasonic Plastic Welding Machines ultrasonic welding systems are based on friction principles. High frequencyn vibrations generally 20khz, This will led to melding of thermoplastic which further led to joining of plastic parts. Mostly all thermoplastics are being welded by ultrasonic.

Ultrasonic Plastic Welding Machine

Get Price Quote

We are the well- known as the foremost Ultrasonic Plastic Welding Machine Manufacturer and Supplier, based in India. The demand for our Ultrasonic Plastic Welding Machine has gradually increased over the time, owing to its efficiency and durability. Our Ultrasonic Plastic Welding Machine is offered at affordable prices. Attributes Extremely low rejection ratesInstance high strengthLow energy consumptionFast processing timesClean weld seams Used For StackingEmbeddingRivetingForming Main Components Transducer /booster/ sonotrodePneumatic Press and Control UnitElectronic ultrasonic Generator Working The Generator supplies the transducer with an alternating current of a given ultrasonic frequency. This is then converted by the transducer into mechanical / ultrasonic vibrations that are finally transmitted via, the booster and sonotrode to the item being welded. Unique Features MicroprocessorUse of printer of welding cycle analysis & parameter settingWelded box structured pneumatic pressOption force triggeringModular designBuilt in electronic amplitude setting: to choose amplitudes between 70% to 100%Energy mode optionAccurate time setting with least count of 0.001 secondShake of pulse-additional ultrasonic vibration at the end of cycleSelf diagnosis-Microprocessor of system Automatic tuning of horn & horn life indication Applications PackagingTelecommunicationsGift and noveltiesTextilesElectronicsAutomativeStationeryWhite goods

Ultrasonic Loop Handle Welding Machine

75,000 Per Piece

Semi-closed Ultrasonic Plastic Welding

Get Price Quote

Product Introduction : If a product has two or more positions to be welded at different welding parameters, the multi-station welder can be used to greatly increase production efficiency. Core Technologies: . Large size and double column high strength frame, high-rigidity without deformed; . Leading screws system combined with dovetail groove slide for adjusting height convenient and stable;. HISAK rolling ball linear slide movement ensure welding operating sensitively and precision; . AIRTAC pneumatic component durability;. Normal temperature-circulation self-cooled ultrasonic generator with original vertical type, the lowest failure rate of the industry;. Frequency-tracking circuit can be dynamically matched with instantaneous changing of welding load;. Constant power output circuit never overload for avoiding poor welding;. SMC pressure sensing protection for avoiding mass defective products;. Lowest power self-check function be sensitive to poor welding;. SCM logic control, accurate and stable; . Digital touch panel (HMI) in English, convenient for setting and adjusting parameters; . Global leader in digital adjustable mode pressure ultrasonic trigger system (national patent); . Import from Japan piezoelectric ceramic transducer, high quality output;.CE&ISO9001 certificated.* Some application examples of high-accuracy ultrasonic welding machine: Auto parts: car audios, foot pads, door panels Electric products: chargers, storage battery, telephones, sockets, flash discs,earphones Medical products: accurate liquid medicine filters,dilators, tee for medicine fillings

Ultrasonic Plastic Welding Machine

Get Price Quote

Being quality centric approach to our organization, we are instrumental in providing ultrasonic plastic welding machines.

ultrasonic plastic welding machines

Get Price Quote

Specifications for ultrasonic plastic welding machine high efficiency converter rigid frame construction pneumatic speed regulator frequency tuning with reading of “idling” & “welding power” on the instrument. triple time for delay time, welding time & holding time. welding pressure adjustable up to 6 bar palm button foot operated switch operation. microprocessor based controller. weld time, hold time settable in the steps of 100 milliseconds. digital counter up to 100,000 counts—resettable. digital bar graph to indicate tuning & energy during the welding cycle. leveling screws provided on the ultrasonic assembly for easy leveling & alignment of horn face with the work piece. Specifications of 3000 watt15 khz. Machine: electrical input: voltage: 230 +- 5 v ac single phase. • current: 12 amps. Max. • power 3 kw. output: frequency: 15 khz. power: 3000 watts. operating frequency: 20 khz. generator dimensions: 580*430*150 feather touch screen for parameter settings on the front panel. two line lcd display for parameter reading & setting. generator weight: 17 kg. co-axial cable length: 3 meters.

Ultrasonic Plastic Welding Machine

Get Price Quote

Our organization is involved in supplying an eclectic array of products out of which is Ultrasonic Plastic Welding Machine. Founded in shahapur(India), our company has been successful in capturing the local and domestic markets as trader of this product

Ultrasonic Plastic Welding Machine

1,550,000 Per unit

Ultrasonic Plastic Welding Machine

Get Price Quote

We are the well- known as the foremost Ultrasonic Plastic Welding Machine Manufacturer and Supplier, based in India. The demand for our Ultrasonic Plastic Welding Machine has gradually increased over the time, owing to its efficiency and durability. Our Ultrasonic Plastic Welding Machine is offered at affordable prices.The Generator supplies the transducer with an alternating current of a given ultrasonic frequency. This is then converted by the transducer into mechanical ultrasonic vibrations that are finally transmitted via, the booster and sonotrode to the item being welded.

Ultrasonic Plastic Welding Machine

Get Price Quote

Ultrasonic assembly is the method of choice for many applications in the automotive, appliance, medical, textile, packaging, toy and electronics markets, among others. The basic advantages of ultrasonic assembly - fast, strong, clean and reliable welds - are common to all markets. However, each market has specialised needs that they rely on ultrasonic assembly to meet.

Ultrasonic Plastic Welding Machine

280,000 Per Piece

Ultrasonic Plastic Welding Machine

Get Price Quote

Sonic Tools manufactures a wide range of Ultrasonic Plastic Welding Machine, which is used in several industries for welding of plastics. These machines are hugely demanded due their robust frame, low power consumption and smoke free operation among the clients. We are reckoned as the well known Supplier of Ultrasonic Plastic Welding Machine. Highlighting Features : Short welding timeLow power consumptionHigh welding strengthDo not damage welding surfaceResistance coefficient is very lowDurableLonger service lifeRobust frameSafe to useNo spark during weldingSmoke free operation Applications : Automobile industryFMCG industryPlastic industry Click Here To View More Detail