Long Range Ultrasonic Testing Service

Get Price Quote

Ultrasonic Testing Services

5,000 Per Sample

Looking for Ultrasonic Testing Services Providers

Ultrasonic Testing Services

Get Price Quote

Our ultrasonic testing services provide accurate, non-destructive inspection of materials to detect internal flaws, such as cracks and voids. Using advanced ultrasonic equipment, we emit high-frequency sound waves to analyze the integrity of components and structures. Our skilled technicians interpret the data to identify and assess potential issues with precision. Committed to quality and reliability, we deliver thorough testing and detailed reports, ensuring your materials and structures meet safety and performance standards.

Ultrasonic Testing Services

Get Price Quote

A non-destructive method to check out if there are any cracks or breaks or defects in any object, ultrasonic testing is imperative in many industries. It uses high frequency sound waves to pass through surface and test it for a variety of things. At Dwija Engineering LLP, we use these ultrasonic waves and pass them through different surfaces to check the thickness or defects in the thing. We are working in Ahmedabad (Gujarat, India) and you can get these services from us at a cost effective cost. Our quote is extremely amazing and you can get these ultrasonic testing services from professionals.

Ultrasonic Testing Service

Get Price Quote

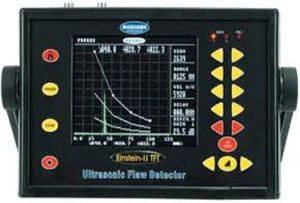

Trinity NDT is your premier source for Ultrasonic Testing (UT) services. With a strong commitment to precision and safety, we offer a comprehensive suite of Ultrasonic Testing solutions to assess the integrity and reliability of critical components and materials across various industries. Our Ultrasonic Testing Services Include: Ultrasonic Flaw Detection: Trinity NDT utilizes cutting-edge ultrasonic technology to detect and locate internal and external defects, cracks, inclusions, and other anomalies in materials, structures, and components. Thickness Measurement: Our experts perform accurate thickness assessments to ensure the safety and longevity of your assets, making this service vital for industries such as manufacturing, petrochemical, and pipeline inspection. Weld Inspection: We specialize in examining welds and weld zones to verify their structural integrity and compliance with industry standards. Advanced Ultrasonics: Our services include advanced UT techniques such as phased array and time-of-flight diffraction (TOFD), offering higher sensitivity and detailed imaging capabilities. On-Site Inspections: Trinity NDT provides on-site and in-field testing services, ensuring the convenience of inspections at your location. With extensive experience across industries like aerospace, automotive, oil and gas, manufacturing, and more, Trinity NDT is a reliable partner for your Ultrasonic Testing needs. We uphold strict quality and safety standards, guaranteeing the utmost accuracy and dependability in our services. Contact us today to discover how Trinity NDT's Ultrasonic Testing services can help you maintain the safety and performance of your critical assets.

Ultrasonic Machine Testing Services

Get Price Quote

Ultrasonic Machine Testing Services Ultrasonic Testing makes use of high-frequency sound waves to perform examinations and make measurements. Eram Marine, a prominent service provider, makes use of engineering applications. It can be flaw detection or evaluation, dimensional calculation, or material characterization. The technique is also usually used to find out the thickness of the test objects or to discover additions to products. The waves are calculated and compared to standards for verification. Our team of professionals has years of experience and practise in handling ultrasonic machine testing services. If you have any doubts, contact our team now for more information!

Ultrasonic Testing Services

Get Price Quote

• ultrasonic testing • in ultrasonic testing (ut), the very short frequency ultrasonic pulse-waves with frequencies ranging from 0.1-15 mhz and occasionally up to 50 mhz are transmitted into materials to detect internal flaws or to characterize materials. A common example is ultrasonic thickness measurement, which tests the thickness of the test object where other side is not accessible like pipes and pipe corrosion. • ultrasonic testing is often performed on steel, other metals and alloys, though it can also be used on concrete, wood and composites, albeit with less resolution. It is a form of non-destructive testing used in many industries including aerospace, automotive and other transportation sectors. • • it works on the principle of high frequency sound waves travelling in a solid medium and the waves and its back echo to give scan results. Even jobs in which the other side is not accessible (as needed in radiography testing) the ultrasonic testing can be done .there is recording system in the digital ultrasonic machines where complete scanning can be recorded. The ut machines are operated by chargeable batteries and therefore can be taken easily at site even at heights.

Ultrasonic Concrete Testing Services

Get Price Quote

Established in 2011, we have been providing ultrasonic concrete testing services to the clients throughout Delhi. We have a support of in-house testing facility and a team of diligent individuals. Thus, we are able to carry out analysis and provide results within the said timeline. Besides, we keep our resources up-to-date in order to provide first-class solutions. So, get associated with us and avail the benefits of cost-effective solutions.

Ultrasonic Testing Services

Get Price Quote

Ultrasonic Testing is family of Non Destructive Testing Techniques best on the propagation of ultrasonic waves in the object or material tested. There are two methods of receiving the ultrasound waveform, reflection and attenuation. In reflection (or pulse-echo) mode, the transducer performs both the sending and the receiving of the pulsed waves as the "sound" is reflected back to the device. Reflected ultrasound comes from an interface, such as the back wall of the object or from an imperfection within the object. The diagnostic machine displays these results in the form of a signal with an amplitude representing the intensity of the reflection and the distance, representing the arrival time of the reflection.

Long Range Ultrasonic Testing Service

40,000 Per Day

Long Range Ultrasonic testing(LRUT)Ultrasonic testing over a long distance is a quick approach to check for corrosion in pipelines. The approach can screen up to 100 metres of pipeline in a single test, 50 metres in each direction. Because of the high production coverage rates compared to manual techniques, LRUT has been used to screen piping systems above ground, but it is still the only reliable technique for screening pipe systems underground or underwater, where access is often limited or very costly for manual contact techniques. The technology is still improving, and the number of apps that use this system has grown significantly.A wave maker device drives low frequency (20-100 kHz) ultrasonic waves longitudinally through the pipeline wall by placing a ring of transducers around the pipeline. The approach succeroblems. At the same time, this allows for thessfully identifies changes in the cross-section of the pipeline, allowing it to detect corrosion and other p use of welds and flanges as distance markers.Long Range Ultrasonic Testing (LRUT) is a technique that involves placing an array of probes in a belt that is circumferentially wrapped around the pipe being inspected. The system then generates ultrasonic guided waves that travel longitudinally down the length of the pipe. The distance covered by the ultrasonic waves is determined by a variety of elements including pipe coating, branch connections, fittings, and whether the pipe is above ground or buried. As a result, the system can inspect both ways from each inspection location, maximising production.Long-Range Ultrasonic Testing Benefits (LRUT) Traditional ultrasonic procedures are more than 100 times faster. On pipelines above ground, screening distances of up to 100 metres are possible. On subterranean pipelines, a screening distance of up to 10 metres is possible. Subsea scanning is a possibility. The pipe wall is completely covered in screening. For pipe integrity management programmes, a cost-effective option is available.

Ultrasonic Testing Services/ Ultrasonic Flaw Detection

1,000 - 3,000 Per Day

We are providing a quality proven range of Ultrasonic Testing Services to our prestigious clients. In this ultrasonic testing service, we utilize high-frequency sound waves which test a material for any defects and flaws. This testing solution is suitable for all types of industries like automobiles, aeronautical, railways, forging & casting, petrochemical and power plants.

Ultrasonic Testing Service

5,000 Per Per day

Ultrasonic Testing

Get Price Quote

Ultrasonic testing techniques that can detect common and uncommon discontinuities caused by base material processes and fabrication. We are experts in detecting flaws found in ingots, continuous castings, billets, plate and sheets, bar and rod, pipe and tubular products, forgings, castings, composites, and welds etc. Our certified staff of NDT technicians provide quality inspection services for a broad range of industry sectors throughout the NDT UT services are offered in our laboratories, field locations and/or customer premise

Ultrasonic Testing Services

Get Price Quote

Ultrasonic Testing is an NDT method applied to detect internal flaws in materials, components and structures. Ultrasonic is sound beyond the human audible range that is 20 to 20 kHz. Ultrasonic inspections use frequencies of above 0. 5 MHz up to 25 MHz to test metals, ceramics, glass, composite and other engineering materials. Ultrasonic testing is commonly used for inspecting castings, rolled bars, plates, forgings, thin sheets, extruded components, drawn components, welds and to measure reduction in thickness of pipes, vessels and other components.

Ultrasonic Testing Services

Get Price Quote

Ultrasonic testing (UT) is a family of non-destructive testing techniques based on the propagation of ultrasonic waves in the object or material tested. In most common UT applications, very short ultrasonic pulse-waves with center frequencies ranging from 0.1-15 MHz, and occasionally up to 50 MHz, are transmitted into materials to detect internal flaws or to characterize materials. A common example is ultrasonic thickness measurement, which tests the thickness of the test object, for example, to monitor pipework corrosion. Ultrasonic testing is often performed on steel and other metals and alloys, though it can also be used on concrete, wood and composites, albeit with less resolution.

Ultrasonic Testing Services

Get Price Quote

Ultrasonic testing (ut) in most common ut applications, very short ultrasonic pulse-waves with center frequencies ranging from 0.1-15 mhz, and occasionally up to 50 mhz, are transmitted into materials to detect internal flaws or to characterize materials. It is used in many industries including steel and aluminium,construction,metallurgy,manufacturing, aerospace, automotive &other transportation sectors. In service ultrasonic testing for preventive maintenance is used for detecting impending failure of rail road rolling stock axles, press columns, earth-moving equipment, mill rolls, mining equipment and other machines and components. The flaws to be detected include voids, cracks, inclusions, pipe, laminations, bursts and flakes. They may be inherent in the raw materials, may result from fabrication and heat treatment, or may occur in service from fatigue, corrosion or other causes. Ultrasonic testing can also be used to measure thickness of metal sections during manufacturing and maintenance inspections

Ultrasonic Testing

Get Price Quote

High frequency sound waves are sent into a material by use of a transducer. The sound waves travel through the material and are received by the same transducer or a second transducer. The amount of energy transmitted or received and the time the energy is received are analyzed to determine the presence of flaws. Changes in material thickness, and changes in material properties can also be measured. Used to locate surface and subsurface defects in many materials including metals, plastics, and wood. Ultrasonic inspection is also used to measure the thickness of materials and otherwise characterize properties of material based on sound velocity and attenuation measurements.

Ultrasonic Testing

Get Price Quote

Ultrasonic testing (UT) is a family of non-destructive testing techniques based on the propagation of ultrasonic waves in the object or material tested. In most common UT applications, very short ultrasonic pulse-waves with center frequencies ranging from 0.1-15 MHz, and occasionally up to 50 MHz, are transmitted into materials to detect internal flaws or to characterize materials. A common example is ultrasonic thickness measurement, which tests the thickness of the test object, for example, to monitor pipework corrosion. Ultrasonic testing is often performed on steel and other metals and alloys, though it can also be used on concrete, wood and composites, albeit with less resolution. It is used in many industries including steel and aluminum construction, metallurgy, manufacturing, aerospace, automotive and other transportation sectors.

Ultrasonic Testing of Concrete

Get Price Quote

We offer services for testing concrete, where the velocity of ultrasonic pulses is measured and identification of cracks, voids, strength, and elasticity are checked to determine the areas which can provide the basis for recognizing the defects. The pulse velocity in a material depends on its density and its elastic properties, which in turn are related to the quality and the compressive strength of the concrete. In ultrasonic testing, very short ultrasonic pulse-waves with centre frequencies ranging from 0.1-15 MHz and occasionally up to 50 MHz are launched on the material to detect internal flaws or to characterize the material. The testing is done through methods such as ‘Reflection’ and ‘Attenuation’. In reflection mode, the transducer performs both the sending and the receiving functions of the pulsed waves; as the “sound” is reflected back to the device. Reflected ultrasound comes from an interface, such as the back wall of the object or from an imperfection in the object. The diagnostic machine displays these results in the form of a signal with an amplitude representing the intensity of the reflection and the distance, representing the arrival time of the reflection. In attenuation mode, a transmitter sends ultrasound through one surface, and a separate receiver detects the amount that has reached it on another surface after travelling through the medium. Imperfections or other conditions in the space between the transmitter and receiver reduce the amount of sound transmitted, thus revealing their presence. Using a couplant increases the efficiency of the process by reducing the losses in the ultrasonic wave energy due to separation between the surfaces.

Ultrasonic Pulse Velocity Testing

Get Price Quote

We offer Ultrasonic Pulse Velocity Testing services according to IS – 13311 (Part 1): 1992. Located in Maharashtra (India), our services are highly in demand. This method is used for testing ultrasonic pulses that are transmitted through the concrete. In solids, the particles can oscillate along the direction of sound propagation as longitudinal waves, or the oscillations can be perpendicular to the direction of sound waves as transverse waves. At surfaces and interfaces, various types of elliptical or complex vibrations of the particles occur. Our instrument is dependent on Dynamic Young’s Modulus, density, and Poisson’s ratio of the material. A complex system of stress waves is developed which includes longitudinal (Compressional), shear (transverse) and surface (releigh) waves. Piezoelectric transducers are designed to generate longitudinal and transverse (shear) waves. The active element of most acoustic transducers is piezoelectric ceramic. These transducers convert electrical signals into mechanical vibrations (transmit mode) and mechanical vibrations into electrical signals (receive mode). The travel time is measured with an accuracy of +- 0.1 microseconds. Transducers with natural frequencies between 20 kHz and 200 kHz are available, but 50 kHz to 150 kHz transducers are common.