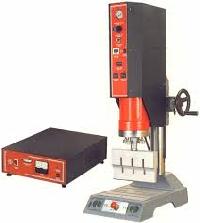

Ultrasonic Hand Welding Set

195,000 - 195,000 Per Piece

1 Piece (MOQ)

Ultrasonic Hand-Gun Welding system

Get Price Quote

This Ultrasonic Hand-Held Welding System Is Being Successfully Used In Cooler Industry – Mainly For Fixing Holding Brackets In Corner Of Lower Body Of Cooler – These Brackets Later Used To Hold The Upper Part Of The Cooler.Screws Used To Get Jammed Due To Rusting Thus Makes It Very Difficult For The Technician To Open It For Any After Sales Service.This New Ultrasonic Welding Eradicate All The Mess And Makes The Opening Very Ease Even After Many Years Of Operation. This System Is Also Being Used For Fixing Fancy Articles On The Front Panel Of The Cooler.It Helps In Minimizing The Cost And The User Gets A Fast Return Of Investment.20 KHz Ultrasonic System Is Practically Being Used In the Cooler Industry.

Best Deals from Ultrasonic Welding System

Ultrasonic Welding Systems

450,000 Per Piece

Linear Ultrasonic Plastic Welding Systems

Get Price Quote

As a joining process for industrial thermoplastics, the ultrasonic method is very well proven in practice. Particularly in the production of mass- produced parts, the process offers definite advantage over previous methods such as for instance high strength, clean weld seams, fast processing time, extremely low rejection rates and low energy consumption. In addition,this technique can be used successfully for riveting, forming, stacking as well as embedding of metal parts into thermoplastic materials.

ultrasonic welding system

Get Price Quote

We offer ultrasonic cleaner baskets that are of high quality. These are manufactured to mainly clean tools in large batches. They operate with low noise and have conveniently designed applications to be paused in the middle of the operation. These cleaner baskets satisfy the cleaning requirements of our clients across several segments. We offer high capacity cleaner baskets with digital display in varied sizes.

Linear Ultrasonic Plastic Welding Systems

Get Price Quote

REDEFINING THE LIMITS OF WELDING As a joining process for industrial thermoplastics, the ultrasonic method is very well proven in practice. Particularly in the production of mass- produced parts, the process offers definite advantage over previous methods such as for instance high strength, clean weld seams, fast processing time, extremely low rejection rates and low energy consumption. In addition,this technique can be used successfully for riveting, forming, stacking as well as embedding of metal parts into thermoplastic materials. Each ultrasonic welding installation comprises the following main components: Electronic ultrasonic Generator Transducer,booster and sonotrode Pneumatic Press and Control Unit The Generator is the heart of every ultrasonic welding system, its function being to supply the transducer with an alternating current of a given ultrasonic frequency. This is then converted by the transducer into mechanical / ultrasonic vibrations which are finally transmitted via, the booster and sonotrode to the item being welded. Unique Features Precise time setting with least count of 0.001 second, thus avoiding over welding, deformation, reduction of production rate and excess consumption of power. Additional ultrasonic vibration at the end of cycle resulting into removal of particles from horn. Self diagnosis-Microprocessor allows operator to rectify the system. Automatic tuning of horn & horn life indication, easy capacity upgradation, amplitude setting without changing the booster. Energy mode option in addition to time mode allowing precise setting of energy as per job requirement.

ultrasonic plastic welding system

Get Price Quote

ultrasonic plastic welding system, ultrasonic spare parts

Robotic Ultrasonic Welding System

Get Price Quote

Robotic Ultrasonic Welding System, client maintenance

Schunk Ultrasonic Welding Systems

Get Price Quote

Schunk Ultrasonic Welding Systems, Shut Height Gauge

Ultrasonic Hand Held Welding System

Get Price Quote

Ultrasonic Hand Held Welding System, Ultrasonic Cutter