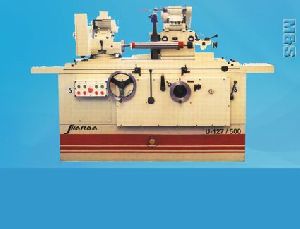

Universal Cylindrical Grinding Machine

Get Price Quote

universal tool grinding machine

Get Price Quote

We are offering you the best quality "SIGMA" Universal Tool and Cutter Grinders. Customers are eased with the availability of the universal tool and cutter grinders with all the advanced facilities including all possible accessories for various grinding operations. This machine is basically designed for re-sharpening, finish grinding & reconditioning wide range of high speed and carbide tools such as side & face milling cutters, cylindrical cutters, angle cutters, convex & concave cutters, gear hobs, end mills, shell mills, reamers, drills, taps etc. 1] Model UTC250TM: Max Swing on centre 250mm & ABC = 440mm 2] Model UTC250T: Max Swing on centre 250mm & ABC = 670mm 3] Model UTC280T: Max Swing on centre 280mm & ABC = 760mm

Best Deals from Universal Grinding Machines

Universal Grinding Machines

950,000 - 1,150,000 Per Piece

1 piece (MOQ)

By using quality packing material, we make sure that the products are properly packed and there will be zero damage during transit. Moreover, our packaging experts stringently check the entire lot before making the final dispatch. We are acknowledged for entertaining voluminous orders at a time as we are supported by streamlined inventory management system and capacious storage facility. Approx. Price: Rs 7.35 Lakh / UnitProduct Details: Auto in feed at reversal(Optional) - 0.01 mm Center Height - 300 mm Distance between Centers - 1250 mm Dwell at Reversals - 0-60 Sec Grinding Wheel (d x w) - 400 x 40 x 127 mm Internal Grinding Spindle.(Optional) - 80 x 250 mm Maximum Swivel of Table - 6 Deg Model - PMTU/1250/300 No. Of work head Speed - 16 to 400 Infinitely Variable rpm Table Speed Infinitely Variable - 0.1 - 4 m/min Tail Stock center - 4 mt Wheel head Rapid approach - 50 mm Wheel head Swivel - 30 Deg Work head Center - 5 mt Work head swivel - 60 Deg

Universal Tool & Cutter Grinding Machine

Get Price Quote

Universal Cylindrical Grinding Machines

Get Price Quote

Universal Grinding Machine

600,000 - 1,500,000 Per No

stainless steel universal surface grinder machine

Get Price Quote

Universal Tool Cutter Grinder Machine

200,000 Per Piece

1 Piece (MOQ)

Universal Cylindrical Grinding Machines

Get Price Quote

We are offering The cylindrical grinder can work on a variety of shapes, however the object must have a central axis of rotation. This includes but is not limited to such shapes as a cylinder, an ellipse, a cam, or a crankshaft.

Universal Belt Grinder Machine

110,000 Per Piece

1 Piece (MOQ)

Universal Cylindrical Grinding Machine

Get Price Quote

Universal Cylindrical Grinding Machine

Get Price Quote

Owing to our exceptional automated warehouse, the human interference has decreased that help us to make on-time deliveries as well. With substantial storage space, the products are kept with utmost safety to circumvent loss during loading and unloading. We are a distinguished name in the domain and are placed in Ludhiana(India) from where we operate. Features : Excellent material quality Easily affordable Efficient and reliable Highly desirable work performance

Hydraulic Universal Cylinderical Grienders

Get Price Quote

Sharda - possess long and outstanding experience. In producting high precision Cylindrical Grinding Machines, their endeavour is put up dedicated efforts concentrating the latest technology available and to offer result oriented product to the user which can yield the reward. These machines are emerged out of Proven design, use of selected materials and implementation of proper manufacturing techniques and skill. These machines are capable to achieves a very high degree of accuracy of roundness and cylindricity on job.They are suitable for tool room and production jobs to carry out cylindrical, face internal grinding operations.

Universal Cylindrical Grinding Machines

Get Price Quote

Welcome to the gallery of premium Universal Cylindrical Grinding Machines where you discover real class of grinding products. The astonishing design and multi features of our quality universal cylindrical grinding machines will grab your eyeballs. In addition; we would like to tell you that we have used several advance technologies and equipments for manufacturing the finest and trendiest model of universal cylindrical grinding machines that no other brand can give. We present to you apex quality universal cylindrical grinding machines that comprises of masculine stiffness and extraordinary feature to resist stain in any harsh condition. Our speedy service and cost viability has set an ideal standard in the market. That is why others envy that we are the ruling universal cylindrical grinding machinery supplier in India.

steering joint cross cup

100 - 115 Per piece

100 Dozen (MOQ)

We carved a niche by offering supreme quality Universal Joint Cross Cup. The offered range is manufactured with the high quality raw material procured from reliable sources of the industry keeping in mind set industry norms. It is available in different shapes, sizes and can be customized as per the needs of the clients'. The entire collection of cross cup is available in various specifications as per the requirements of the clients. The above image is of the steering cross cup. We can also do autoblack to it as per ustomer demand. product size- 18.5mm height, 28mm width.

Universal Tool Cutter Grinding Machine

Get Price Quote

Functional Versatility: The instrument basically designed for sharpening and recondition wide range of high speed and carbide tipped tolls as side & face milling cutters, cylindrical cutters, angle cutters, convex & concave cutters, gear hobs, end mills, shell mills reamers, drills, taps etc. Construction: Wheel Head: It is of rigid construction and holds the spindle assembly. It can be fitted horizontally and swiveled vertically full 360 degree, for quick setting of compound angles. Wheel head is mounted on the rigid column, which can be raised/lowered up/down. Wheel head also can be adjusted 150 mm on cross direction. Wheel Head Spindle: Alloy steel hardened and ground spindle is mounted on precision preloaded radial ball bearings, which are greased packed. The grinding wheels can be mounted on both sides of the spindle and the wheels mount design is such that the spindle can be reversed. Work Table: This is mounted on the carriage and can be swiveled 45 degrees on either side of the column. This table has a smoother and rapid movement longitudinally on the carriage through a roller chain guided and supported in jibs. Slow movement is through a reduction gearbox. Change over from rapid to slow movement is through a push/pull knob. The precise movement on roller chain enables smooth, sensitive and accurate longitudinal movement even with heavy jobs. The adjustable reversing dogs on the work table are spring loaded for shockproof reversal of table. Auxiliary Table: This table is mounted on work table and in both horizontal and vertical planes. It can hold job up to 600 mm with the aid of raising blocks. It's spindle nose has ISO 50/MT 5 tapers and the spindle is mounted to taper roller bearings. Standard Equipment Universal cutter head with Mt-3 adopter sleeves Right hand, quick acting spring loaded center tail stock Left hand center tail stock Diamond holder (excluding) Plain tooth rest and extension with one blade Universal tooth rest and extension and micro adjustment to blade Center height gauge Center with morse taper no. 3 Wheel guards with guard holder - 3 nos Grounding wheels - 3 nos All necessary spanners and wrenches Suitable electrical Maintenance and instructions manual Special Accessories Cylindrical external attachment Cylindrical internal attachment A) swivel vice B) 2-way & 3-way swivel vice Face, milling cutter attachment Radius attachments Long reamer grinding attachment Gear milling cutter attachment Angular wheel dressing attachment Radius dressing attachment Hob grinding attachment Dust exhausting unit Static wheel balancing unit Collapsible bellows for column

Universal Grinding Machines

1,200,000 - 2,200,000 Per Number

1 Piece (MOQ)

CNC Universal Grinding Machine

Get Price Quote

3-Axes CNC Universal Grinder ideally suited for external grinding, shoulder and internal grinding operations on mediumsmall size components.

Universal Cylindrical Grinding Machine

1,000,000 Per Piece

1 Piece (MOQ)

PRODUCTS AND SOLUTIONSWe research, test and develop to bring the best Universal Cylindrical Grinding Machine. OUR ETHICSWe care for living and working conditions of our employees and provide a safe, diverse and inclusive workplace. Our compensation and work to life balance meets or exceeds the legally required minimum, lawful working hours.We care for expectations of our collaborators and thrive to fulfill their requirements with highly motivated, skilled ecosystem of our employees. FEATURESThe Universal Cylindrical Grinding machines are designed with vast range of models which can be used effectively on both high production rate or tool room work. All models have mechanical and hydraulic table traverse or CNC machines for production works. We use antifriction Turcite ‘B’ slideway material in the slides in all our models. DESIGNThe precision Universal Cylindrical Grinding Machine is carefully designed with very long time experience and extra ordinary state of art technology. The rigid base of machine with high quality methods and graded cast and heavier rib design for greater strength and absort vibrations while machine is utilize to its full strength. WORK HEADThe work head is designed for rigidity and universal type. The spindle of work head is made of specially alloy steel fitted with ultra precision bearings for long time. The infinite variable speed of work head with optional AC Drive for better performance. Standard models have 3 steps and 4 steps speeds according to size of machine. TAIL STOCKThe tail stock is designed with art of technology for maximum rigidity with special alloy steel material of ram and kept under adjustable spring load. Operation of tail stock is manual and power operated on hydraulic model. WHEEL HEADThe wheel head is universal type and spindle of wheel head is made of special alloy steel and heat treated to achieve high accuracy and stability of machine. CROSS FEEDThe cross feed systems is made of art of technologies for best accuracy and less backlash with accurate graduations of machine. Optional at extra charges preloaded Linear Motion Guidways and Preloaded ground ballscrew for the world class standards to obtain long life and best performance of machine. AUTO CYCLE CROSS FEEDThe automatic grinding cycle for Auto sizer models of machine operates as Rapid Approach – Coarse Feed – Fine – Feed Spark Out- Rapid reaction of wheel head and to the selected position. The auto cycle mode as features to start and stop the work head and coolant automatically. COOLANT SYSTEMThe coolant system is provided with machine with tank and Coolant pump with required accessories. Optional Magnetic Coolant separator, paper band systems are available FEATURES OF PRECISION EXTRA HEAVY DUTY CYLINDRICAL GRINDING MACHINES MECHANICAL/HYDRAULIC/PLC/SIEMENS/ROBOTIC. Rigidly Constructed Graded Grey Casting with Extra Heavy Ribs Tool Room and Mass Production Rapid approach Z and X Axis Variable Speeds of Work Head Antifriction Self Lubrication Turcite Coating on Bed Ways Tapered Angle Table for Best Gripping Head Stock and Tail Stock All Spindles and Shafts made of Nickel Alloy Steel hardened and precisely ground. High precision Class Bearings, Bushes and Spindle Cartridges are available as per Customer’s requirements Precision Class hardened and Ground Ball Screw Preloaded antifriction LM Guide ways / Roller Guide ways as per requirement Power Operated Tail Stock for Hydraulic Machines. Absolute PLC System of latest technologies with FiberOptical Cables to Control interpolation of 2 axis brand Mitsubishi/Siemen’s Absolute CNC System we use latest version of Fanuc/Siemens/Mitsubishi as per Customer’s requirements Hydraulic Power packs Yuken/ Rexroth Energy Efficient Motors and Electrical Switch Gears of World Standards. Centralized automatic Lubrication system for the adequate lubrication Surfaces finish 2 microns (improved RA values can be obtained by using selected grade of grinding wheel applicable to material to be ground). .

Universal Grinding Machines

750,000 Per Piece

1 Piece (MOQ)

we manufacturing 400 to 1000 mm hydraulic grinding machine. our machine accuracy 0.001 mm.