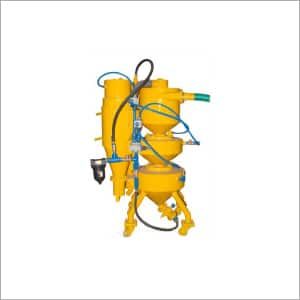

Vacuum Blasting Machine

1,800,000 Per Piece

1 Piece (MOQ)

Vacuum Blasting Machine

Get Price Quote

1 Piece (MOQ)

Best Deals from Vacuum Blasting Machine

BU vacuum blasting machine

Get Price Quote

1 Piece (MOQ)

Vacuum Abrasive Blasting Machine

Get Price Quote

MEC offer portable dust free abrasive blasting equipment with high vacuum power and efficient separation for abrasives & debris. MEC vacuum blasting machines are suitable for different purposes, applications for surface preparation before coating and needs only one man to operate. The blasters are based on pressure vessels in combination with compressed air filters and pressure regulators that ensure sufficient speed of blasting operation in a dust free environment. Abrasive is automatically and instantly recovered for reuse. No flying dust & abrasive to contaminate surrounding. A special valve on pressure vessel allows to work with a blasting pressure as low as 1 bar and as high as 7 bar with the same machine. Vacuum blasting technique can be used on delicate blasting jobs where blasting on low pressures is a must. All MEC vacuum blasting machines comes with a standard special lightweight blast head, blast and vacuum hose assembly, as well as a set of brushes to treat flat surfaces. The very special fibres used in brushes ensure best performance and economy.Our Standard Models MCB-V MCB-X MCB-XV P-14

Vacuum Blasting Machine

Get Price Quote

Features: Noise less operation Power efficient Rugged construction Easy to operate Vacuum Blast Equipment Specifications:Restrictive environmental legislation and a greater awareness of health hazards were the main reasons for development of vacuum blasting equipment. The advantages of the equipment are not limited to preventing environmental and health problems, in many applications it is also a fully justified method of surface preparation on an economic basis. Disposal costs of hazardous waste is minimal by the use of recyclable abrasives, so the amount of abrasives used is much lower than compared with open-blasting. The equipment has many applications. Besides for construction and maintenance of ships, the equipment can also be used for the maintenance of bridges, machinery, power plants or for the renovation of concrete. steel, shipbuilding, offshore and (petro) chemical industries and also for maintenance purpose in the civil works sector such as cleaning bridges , tunnels and buildings etc.The Synco Model : SPBV 08C-1 is a compact and versatile vacuum blasting machine which gives the user flexibility of cleaning components to a depth / height of about 5 mtrs from the machine position. The sturdy construction is designed for rough handling. This model is easy to move to the place of blasting due to its compact size where other machines find difficulty to reach such as submarine holds.

Mobile Close Circuit Vacuum Blasting Machine

Get Price Quote

KU-15C Portable mounted on 4 wheels Uniform cleaning and finishing Vaccum pump recovery Two Gun outlet

Vacuum Blasting Machine

Get Price Quote

Blasting is the simplest and most effective way to remove rust, old paint and other materials from various surfaces. The Nederman vacuum blaster is a clean, dust free vacuum blaster that leaves the surface cleaned and well prepared for auto bodywork filling and painting etc. The grit is recycled and can be reused many times over. The SB 750 vacuum blaster is suitable for smaller-scale and lighter work.

Vacuum Blasting Machine

Get Price Quote

Restrictive environmental legislation and a greater awareness of health hazards were the main reasons for development of vacuum blasting equipment. The advantages of the equipment are not limited to preventing environmental and health problems, in many applications it is also a fully justified method of surface preparation on an economic basis. Disposal costs of hazardous waste is minimal by the use of recyclable abrasives, so the amount of abrasives used is much lower than compared with open-blasting. The equipment has many applications. Besides for construction and maintenance of ships, the equipment can also be used for the maintenance of bridges, machinery, power plants or for the renovation of concrete. The machine therefore is commonly found in steel, shipbuilding, offshore and petro-chemical industries apart from other places.

P-14 Vacuum Blasting Machine

Get Price Quote

We offer Vacuum Blasting Machine. It is a small handy blasting tool for light work, touch-up cleaning and maintenance job. It does blasting in dust free conditions. unit weight: 3.5 kg. Abrasive charge: 1.8 kg. Total weight: 5.3 kg. no special skill required to operate. small enough to be fitted through tank manhole, or into hard to get at areas. ideal for locations where abrasive must be fully contained i.e. Machinery area, electronic equipment etc. swivel head allows blasting at any position-overhead, side-ways, down hand etc. most common re-useable abrasive may be used, such as shot and grit, aluminium oxide etc one-man operation equals three man cleaning by wire brushing, disc sanding or other hand cleaning methods. always ready to use. Attach to 19 mm air line and start blasting. no electrical connections. Requires 33 to 60 cfm at 90 to 100 psi pressure. Best pattern approx. 31.8 mm wide. a while metal surface is obtained suitable for any recoating.

VACUUM BLASTING

Get Price Quote

MEC offer portable dust free abrasive blasting equipment with high vacuum power and efficient separation for abrasives & debris. MEC vacuum blasting machines are suitable for different purposes, applications for surface preparation before coating and needs only one man to operate. The blasters are based on pressure vessels in combination with compressed air filters and pressure regulators that ensure sufficient speed of blasting operation in a dust free environment. Abrasive is automatically and instantly recovered for reuse. No flying dust & abrasive to contaminate surrounding. A special valve on pressure vessel allows to work with a blasting pressure as low as 1 bar and as high as 7 bar with the same machine. Vacuum blasting technique can be used on delicate blasting jobs where blasting on low pressures is a must. All MEC vacuum blasting machines comes with a standard special lightweight blast head, blast and vacuum hose assembly, as well as a set of brushes to treat flat surfaces. The very special fibres used in brushes ensure best performance and economy.

Vacuum Blasting Machine

Get Price Quote

Vacuum Blasting Machine

Get Price Quote

Vacuum Blasting Machine, Portable Sand Blasting Machine, Blast Room System

Vacuum Blasting Machine

Get Price Quote

Vacuum Blasting Machine, tum blast type shot blasting machine, Dust Collector

Vacuum Blasting Machines

Get Price Quote

Vacuum Blasting Machines, blasting machines, electric blasting machines

Vacuum Blasting Machine

Get Price Quote

Vacuum Blasting Machine, Portable Sand Blasting Machine

Vacuum Blasting Machine

Get Price Quote

Vacuum Blasting Machine, Sand Blasting Machine

Vacuum Blasting Machine

Get Price Quote

Vacuum Blasting Machine, Battery Manufacturing Plant

Vacuum Blasting Machine

Get Price Quote

Vacuum Blasting Machine, HVOF Thermal Spray Gun, plasma spray system

Vacuum Blasting Machine

Get Price Quote

Vacuum Blasting Machine, Portable Sandblasting Machine

Vacuum Blasting Machine

Get Price Quote

Vacuum Blasting Machine, shot peening equipment