Hopper Loader Vacuum Conveying System with Online Sieving

Get Price Quote

1 Set (MOQ)

Details: Hopper Loader convey the material from silo mixer or any other storage arrangement. Various models to suit your extruder capacity. Dust free operation. Highly reliable level sensor to ensuring emptiness of material from Silo or extruder hopper. PlC operated state of the art electric control panel.

Stainless Steel Vacuum Conveying System

250,000 Per Piece

1 Piece (MOQ)

Best Deals from Vacuum Conveying System

Sugar Vacuum Conveying System

Get Price Quote

1 Piece (MOQ)

ALTOMECH vacuum conveying system is the ideal solution for safely and reliably moving sugar. Vacuum conveying is the process of using compressed air to move bulk materials through pipelines or hoses from Point A to Point B. With the right system, it is an extremely efficient way to cover distances both vertical and horizontal and also help you to avoid blockages, high energy bills and reduce loading and unloading times to a minimum. Features: Total Discharge no Retention. No segregation or degradation of Product. Transfer can be completely automatic to avoid the manual handling of the material Integrated hi efficiency in-line filter cleaning system Easy to clean and wash of contact parts. Advantages: Easy Maintenance Consumes less energy Contamination Free Material Handling

vacuum conveying systems

Get Price Quote

Vacuum Conveying System

125,000 Per Piece

1 Piece (MOQ)

Vacuum Conveying System

Get Price Quote

Vacuum Conveying System

300,000 - 500,000 Per

Vacuum conveying system is suitable to transfer up to 6000 kg/Hr.Conveying Distance: 3 to 30 meters with long radius bends. Automatic filter bag cleaning system by reverse jet arrangement. Antistatic PTFE coated cylindrical cartridge filters, easy for cleaning Compressed fresh air externally provided with sequence timer which keeps the system clean and maintains conveying efficiency. The Batch receiving hopper with vibrator for free flowing feeding, level sensors, proximity switches and pneumatically actuated discharge valve for feeding to heater mixer.

Vacuum Conveying System

150,000 - 200,000 Per Unit

150000 Unit (MOQ)

vacuum pneumatic conveying system

500,000 Per Piece

1 Piece (MOQ)

Vacuum Conveying System

225,000 Per Piece

01 Piece (MOQ)

pressure conveying system/Vacuum conveying system

200,000 Per Piece

1 Piece(s) (MOQ)

Vacuum Powder Conveying, Transfer System

Get Price Quote

APPLICATION & PROCESS : The Vacuum transfer system is unique dry material transfer system for dust free and avoid to human touch. The vacuum transfer system is used in Pharmaceutical, Food, Agro Chemical, Sugar Industries and chemical. The system is use full for inline milling, sifting, blending, loading and unloading. The principle of vacuum transfer has been proven to be a better way to move many types of material and a giant step over manual handling. The technology exists for moving virtually any material that can be pulled through a hose or tube. The system is consisting of Blower, Vacuum receiver system with filter, cyclone filter and Pipe. The vacuum conveying systems designed specifically for the direct charge loading of blenders, mixers, sifter, milling, reactors or any vessel capable of withstanding a vacuum. The vacuum system can be provided mobile type with lifting provision to move one room to another room for loading and loading any machine. SALIENT FEATURES : Design is cGMP - Current Good Manufacturing Practices compliance. All contact parts AISI 316 & non contact parts AISI 304. Capacity available 100 Kg to 5000 Kg/hr. Can be used for transfer of products having bulk densities up to 1.0gm/cc. Total Discharge no Retention. No segregation or degradation of Product. No tool required for opening & cleaning. Transfer can be completely automatic to avoid the manual handling of the material.

Vacuum Conveying System

200,000 Per Piece

01 Piece (MOQ)

Vacuum Conveying System

Get Price Quote

We are offering vacuum conveying system serves purpose for extremely important needs as required by various industries. The vacuum conveying system is made of durable and sturdy components comprised of high quality. We have developed the vacuum conveying system to respond against the crucial needs while operating with safety and hygiene in the industries.

Vacuum Conveying System

250,000 Per Piece

We are offering Vacuum Conveying System

Vacuum Conveying System

Get Price Quote

» AIR HANDLING ENGINEERING is an art, please consult us for your specific air handling needs. PLC based automatic Flux Supply & Recovery Unit: » Flux supply & recovery unit is working based on vacuum and high pressure pneumatic conveying system. » This system is divided in three assemblies.1. Flux recovery and conditioning assemblyThe flux recovery is based on vacuum conveying system. the additional flux supplied to the welding point will be recovered with use of vacuum conveying and will be stored at recycle flux storage vessel. the dusty air will pass through the reverse pulse jet type filter cleaning arrangement and clean air will be exhaust of to the atmosphere.The recycle flux will be reconditioned with the help of 3 stage flux conditioning unit. the first stage will remove the large slugs particles collected during the suction. the second stage will remove the magnetic particles from the collected flux. the third and final stage will remove the dust particles from the collected flux.The collected flux will be mixed with new flux through flux management system. we had provided two types of flux management system, one is one-by-one timer control system and other-one is online flow control mixing system.In one-by-one timer control system, the new flux and recycled flux will be mixed with the help of set-up timers which can be set in the hmi panel. this mixing ratio can be varied from 20% to 50% new flux to the recycle flux with the use of time control system. in this system, first we will allow to collect recycle flux, then after new flux. such cycle can be repeated depends upon requirements.2. Flux supply assemblyThis mixture of the flux will be transferred to the set of flux supply tanks. these tanks are provided with periphery type surface heater to maintain the temperature of flux to be supplied for the welding purpose. this flux will be transfer through pressure conveying system.

Vacuum Conveying System

Get Price Quote

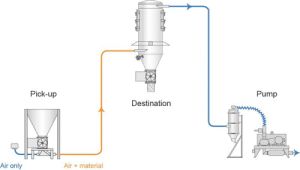

The ultimate Pneumatic Conveying System for handling your difficult to convey materials. Pneumatic Conveying is a widely adopted means of transporting dry bulk material either by Vacuum or by Pressure of Air. Depending on the material to be conveyed, the air stream with specific velocity will carry the material to the final destination. Convenience of routing Pneumatic conveying system horizontally and vertically is an added advantage over other conventional methods of conveying. To be more precise, Pneumatic Conveying system can be used on any circuitous route. Powders, pallets, granular and fibrous materials can be very efficiently conveyed by Pneumatic conveying systems. Features Fast Rate of Conveying Uniform Handling of Material No Spillage of material during handling Very less space requirement for mounting equipment Neat and Clean Operation

Vacuum Conveying System

Get Price Quote

The Pneumatic Conveying is necessarily custom made conveying system & based on product characteristics, particle size, throughput capacity, number of sources and number of destinations. Each pneumatic conveying system is designed & customized as per the application popularly known as custom conveyor system.The provided solution is assured to be the best pneumatic conveying system solution for the application. Being the application experts & pneumatic conveying system manufacturer, we always assure to deliver best of both the worlds (commercial & technical worlds).

Vacuum Powder Conveying/Transfer System

Get Price Quote

Vacuum Powder Conveying/Transfer System Easy dust free Conveying with inline process Application & Process : The Vacuum transfer systemis unique dry material transfer system for dust free and avoid to human touch. The vacuum transfer system is used in Pharmaceutical, Food, Agro Chemical, Sugar Industries and chemical. The system is use full for inline milling, sifting, blending, loading and unloading. The principle of vacuum transfer has been proven to be a better way to move many types of material and a giant step over manual handling. The technology exists for moving virtually any material that can be pulled through a hose or tube. The system is consisting of Blower, Vacuum receiver system with filter, cyclone filter and Pipe. The vacuum conveying systems designed specifically for the direct charge loading of blenders, mixers, sifter, milling, reactors or any vessel capable of withstanding a vacuum. The vacuum system can be provided mobile type with lifting provision to move one room to another room for loading and loading any machine. Salient Features : Design is cGMP - Current Good Manufacturing Practices compliance. All contact parts AISI 316 & non contact parts AISI 304. Capacity available 100 Kg to 5000 Kg/hr. Can be used for transfer of products having bulk densities up to 1.0gm/cc. Total Discharge no Retention. No segregation or degradation of Product. No tool required for opening & cleaning. Transfer can be completely automatic to avoid the manual handling of the material Fully automatic system, with timing controls and automatic air blow back system for filter cleaning. Vacuum Blower and cyclone filter can be installed in out side production area. Avoids product waste, loss and contamination. Easy to clean and wash of contact parts. Option for Inline Milling, Sifting with Blender and Loading material to RMG, Tablet press& Vessel.

Vacuum Conveying System

150,000 Per unit