Vacuum Powder Transfer System

Get Price Quote

3 Piece (MOQ)

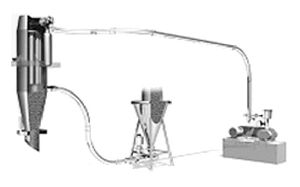

VACUUM POWDER TRANSFER SYSTEM (VTS) - (Capacity: Up to 3000 Kgs/hr) GMP Model VACUUM TRANSFER SYSTEM is unique equipment used for Transferring the powder/product into process equipment. By using this equipment, a dust free charging can be done as compared to conventional type or manually charging. This equipment comprises of two units. One is the Vacuum Blower and Other one is a powder receiver bin with filtration unit. Powder receiver Bin located above the equipment which you intend to transfer powder/ product. These units will be connected through a food grade flexible thunder hose. SALIENT FEATURES Manufactured as cGMP Norms. Vacuum Blower is used. Which eliminates lubrication system and Motor, Pulley V Belt Etc. . Consumes 40% power compared to the other conventional Equipment. All sides on the shell are curved construction. Totally eliminates sharp corners and cleaning difficulty. Finish: Inside : Mirror Polish Out Side Matt polish Capacity : UP to 3000 Kg/Hr.

vacuum transfer system

Get Price Quote

We are amongst the reputed manufacturers and suppliers of Vacuum Transfer Systems. The use of IPC minimizes the overall amount of handling that occurs in a manufacturing process and other such process. Available in different capacities ranging from 25 liters to 1500 liters, these containers offer many benefits including automation capability and dust free product transfer. Salient Features of Vacuum Transfer System : It helps to control containment and cross contamination Provided with butterfly valve for discharge Personal safety Effective process & unit operation feed Reduction in segregation

Best Deals from Vacuum Transfer System

vacuum transfer system

150,000 - 300,000 Per Uni

150000 Unit (MOQ)

Vacuum Transfer System occurs when a material is conveyed in suspension in the flowing air.Advantages-- Low Air Consumption- Little or no degradation of fragile material- Optimum solids to Air Ratio & Conveying Velocity- No Spillage, dust free & no hygiene problems during product handling

Vacuum Powder Transfer System

Get Price Quote

EMCO VTS technology provides innovative solutions for automated transfer, dosing and packaging of powders by means of vacuum and pressure. VTS with its unique filtration concept makes the only vacuum dense-phase system that functions at optimum levels when handing ultra-fine, sticky and adhesive powders. VTS* (Vacuum Transfer System) Dust Free Filling and discharging Packaging Dosing No product retention No particle damage Easy to clean

vacuum transfer system

200,000 Per

1 Piece (MOQ)

Vacuum Aspiration System

Get Price Quote

100 Piece (MOQ)

Vacuum power can be set to different levels to achieve 1mL/S to 15mL/ S aspiration speed Sensitive level sensor to prevent liquid overflow during operation Fully autoclavable waste collection bottle, tubing and handle Lid, tubing and handle are easy for disassembling, cleaning and autoclaving Wide range of adapters to fit tube, microplate and disk plate for various tasks Interchangeable hand operator -tip adapters make it suitable for various tasks from single channel to 8-channel based on the applications in tube, micro plate, disk plate etc.

Stainless Steel Powder Vacuum Transfer System

Get Price Quote

1 Unit (MOQ)

vacuum transfer system

205,000 Per Piece

vacuum transfer system

800,000 - 850,000 Per Piece1

vacuum transfer system

Get Price Quote

Vacuum tablet press loading systems are furnished as complete, ready-to-operate systems for mounting on customers’ presses. Available for single or dual hopper tablet presses The loader eliminates manual scooping of product and messy dumping or mishandling. Draw material directly from drums, boxes, storage containers, process vessels.Thus Vacuum Loading reduces the manual labor intensity,to eliminate the dust pollution to ensure the production line with GMP.

vacuum transfer system

Get Price Quote

We are amongst the reputed manufacturers and suppliers of Vacuum Transfer System. The use of IPC minimizes the overall amount of handling that occurs in a manufacturing process and other such process. Available in different capacities ranging from 25 liters to 1500 liters, these containers offer many benefits including automation capability and dust free product transfer.

gansons vacuum transfer system

Get Price Quote

Gansons Vacuum Transfer System is an effective and reliable solution for closed-loop transfers of powders and granules with varied bulk densities and particle sizes. The flow type can be optimised and controlled based on material properties and the desired output.

vacuum transfer system

Get Price Quote

Design is cGMP – Current Good Manufacturing Practices compliance. All contact parts AISI 316 & non contact parts AISI 304. Capacity available 100 Kg to 5000 Kghr. Can be used for transfer of products having bulk densities up to 1.0gmcc. Total Discharge no Retention. No segregation or degradation of Product. No tool required for opening & cleaning. Transfer can be completely automatic to avoid the manual handling of the material Fully automatic system, with timing controls and automatic air blow back system for filter cleaning. Vacuum Blower and cyclone filter can be installed in out side production area. Avoids product waste, loss and contamination. Easy to clean and wash of contact parts. Option for Inline Milling, Sifting with Blender and Loading material to RMG, Tablet press& Vessel.

vacuum transfer system

Get Price Quote

Available in Size 12", 24", 30", 36", 48" and 60" Inch. Salient Features:- Available in standard cGMP and customized models with SS304/SS316/SS316L Contact Part. It helps to control containment and cross contamination Provided with butterfly valve for discharge Effective process & unit operation feed Personal safety Reduction in segregation

vacuum transfer system

Get Price Quote

Description The system comprises a twin lobe vacuum duty air cooled pump, a cyclone separator, a bypass valve damper, two stage food grade silicon coated polyester filters, associated pipe lines and the food grade hose pipe with pickup device. Salient Features The entire assembly and dismantling is devoid of any fasteners, using quick release clamping systems. All the product pipe lines are internally electro-polished. The PTS body is designed to avoid the retention of product. The filter bags are continuously unclogged with the help of timer based pulse jet valve. The output rate would be anywhere between 600 Kg/Hr. to 2000 Kg/Hr, for material transferred between bulk density range of 0.25-1 gm/cc. Sugar conveying is easily available at an output rate of around 2000 kg/Hr.

Vacuum Transfer Systems

Get Price Quote

he conventional vacuum charging system is a sophisticatedly designed system that makes the use of IPC, which minimizes the overall amount of handling. It works on the principle to move different types of material that can be pulled by a hose or a tube. Some of the main components of conventional vacuum charging system include, blower, vacuum receiver system with filter, cyclone filter and a pipe. Specialized in different kinds of material transfer processes Characteristic features Parts configured with SS 316 material mainly Filters made specially with non woven fabric and washable material Filter assembly and collection port covered with toggle clamp which minimizes the use for cleaning Saves manpower Time based convey cycle and discharge cycle in vacuum transfer systems Manual handling available that fosters saving of wastage of material Incorporated butterfly valve for the purpose of easy discharge Effective process and unit operation feed Used extensively in pharmaceutical industry, food and chemical industries. Timer based vacuum transfer system with timely updates on the system Minimized segregation available in the powder vacuum system Personal safety ensured in the vacuum transfer system Flexible in installation and user friendly conventional vacuum charging system An enclosed system that controls cross contamination Easy maintenance due to less moving components Sequential timer based system with four operation cycles Advanced control systems that make the operation more convenient A finely equipped vacuum safety valve for safety considerations Control panel made with SS 304 material, configured with dust proof construction

vacuum transfer system

Get Price Quote

vacuum transfer system, Auto Coater, Sizing Machine, Turbo Sifter

Farmacal Chemical Vacuum Transfer System

Get Price Quote

Farmacal Chemical Vacuum Transfer System, Fluid Bed Dryer

vacuum transfer system

Get Price Quote

vacuum transfer system, Rotary Tablet Compression Machine

vacuum transfer system

Get Price Quote

vacuum transfer system, SS Wardrobe, Vibro Sifter, SS Mixing Vessels

Vacuum Transfer Systems

Get Price Quote

Vacuum Transfer Systems, Bottle Air Jet Vacuum Cleaning Machine

vacuum transfer system

Get Price Quote

vacuum transfer system

vacuum transfer system

Get Price Quote

vacuum transfer system, die head machine, pencil making machine

vacuum transfer system

Get Price Quote

vacuum transfer system, Contra Rotary Mixer, Bottom Magnetic Mixer

vacuum transfer system

Get Price Quote

vacuum transfer system, High Shear Mixer, Vacuum Tray Dryer, air tray dryer

vacuum transfer system

Get Price Quote

vacuum transfer system, air jet cleaning machine, Packing Conveyor

vacuum transfer system

Get Price Quote

vacuum transfer system

vacuum transfer system

Get Price Quote

vacuum transfer system, ROTOCONE VACUUM DRYER, Alu Alu Packing Machine

Vacuum Transfer System For Powders

Get Price Quote

Vacuum Transfer System For Powders, Bulk Bag Unloading Station