vci master batch

850 Per Kilogram

10 Kilogram (MOQ)

VCI Masterbatch

550 Per Kilogram

We offer masterbatch for the VCI film in white and yellow color for film extrusion

Best Deals from VCI Master Batch

VCI Masterbatch

200 - 500 Per Kilogram

2000 Kilogram (MOQ)

VCI Masterbatch

450 Per Kilogram

100 Kilogram (MOQ)

VCI Masterbatches

650 Per Kilogram

VCI Masterbatch

Get Price Quote

VCI Master Batches

Get Price Quote

vci master batch

850 Per Kilogram

100 Kilogram (MOQ)

Anti Corrosion Films VCI Batch

Get Price Quote

vci master batch

Get Price Quote

VCI Masterbatch manufactured by RustX is the most advanced corrosion protection Masterbatch for VCI film manufacturing It is a nitrite free VCI Masterbatch there is impregnated with specialised VCI chemicals for corrosion protection of metals and nonmetals and is a multimetal product. This is based on SMP technology which stands for speedy moisture passivation in which 20% of the VCI is released within six hours of opening the VCI film bag and remaining 80% over a period of 15 years. VCI vapours are released over period of time which react with moisture or water molecules and neutralise them so where ever they settle on the metal part The new molecule is neutral to corrosion. A PH value of 8 to 9 is maintained in the packaging hence inhibiting any corrosion of the parts as the corrosion can only take place where there is high moisture or Acidic content in the packaging It is very easy to extruded the film in most extruders using rest X VCI masterbatch. The product is reach approved, ROHS compliant, TRGS615 compliant, heavy metals free, nitrite free and does not have a very strong odour. The resin is clear and when extruded with LDPE, Hdpe or PP and does not release any gasses during the manufacturing and does not believe any residue in the extras in machine or on the rollers, die, screw, barrel or airings. How to test VCI quality and performance? VCI masterbatch can be validated using a very simple test where a few drops of water can be put in RustX with a steel blade and on the other side in a normal plastic bag with a few drops of water and a steel blade. What you shall notice is that there would be corrosion in the normal bag within a few minutes to a few hours and the rustics we see a film will not have corrosion even four years with doors few drops of water inside the bag. Application VCI MASTERBATCH VCI Masterbatch 3100 PC can be blended with polyethylene resin (LDPE/ LLDPE/ HDPE) depending on the thickness of the film or application and requested shelf life. The length of protection anticipated by film containing VCI Masterbatch 3100 PC is 5 years when extruded with ideal processing guideline. We recommend that an evaluation is made in every single case to confirm that the anticorrosion effect is fulfilling the demands. Safety Information & Declaration RUST-X products don’t contain Lead (Pb), Mercury (Hg), Cadmium (Cd), Hexavalent Chromium (Cr6),Polybrominated biphenyls (PBB), or Polybrominateddi-phenylether complying with the re-stricted substances listed in Article 4(1) of the RoHS Directive.RUST-X products are also REACH & ROHS Compliant for exports to the European

VCI Masterbatch

2,000 Per Kilogram

100 Kilogram (MOQ)

VCI Masterbatch

Get Price Quote

VCI White Masterbatch, corrosion control equipment, Zorbit Container Sack

VCI Masterbatches

Get Price Quote

From Delhi, India, we bring forth a wide gamut of VCI Masterbatches that are used to produce VCI polythene bags. We make use of quality-tested raw material for manufacturing these VCI Masterbatches. Securely packed as per the buyer’s needs, our VCI Masterbatches are priced pretty well for the ease of buyers. We are renowned Manufacturer, Exporter as well as Supplier of VCI Masterbatches and widely admired for steady deliveries, of the consignments. VCI means Volatile Corrosion inhibitor or Vapor Corrosion Inhibitor. VCI Masterbatch is a linear low-density polyethylene VCI masterbatch additive. It contains a proprietary formulation and is used as a masterbatch additive for the production. VCI Masterbatch additive is specially formulated for corrosion protection of both ferrous and non-ferrous metals. It is safe and does not require any changes in the manufacturing process. The let down ratio for VCI Masterbatch is one of the lowest available in the industry.VCI Masterbatch additive has a broad spectrum of formulation applications and is currently being used for the production of VCI polyethylene bags, shrouds, tubing film, U-film and sheeting films. Depending on the resin carrier used, VCI Masterbatch can also be used in the production of VCI Blown Stretch Film, VCI Shrink Film, VCI Corrugated Plastic Containers, VCI Injection Molded Parts and VCI Foam and VCI Bubble Wrap.VCI Masterbatch is 100% Nitrite Free.With the introduction of VCI Masterbatch Resins can be produced at a very competitive price anywhere in the World. VCI Masterbatch is a specialty value added additive that provides superior corrosion protection.ApplicationVCI Masterbatch can be blended with polyethylene resin (LDPE/ LLDPE/ HDPE) depending on the thickness of the film or application. Our recommendation to evaluation is made in every case to confirm that the anticorrosion effect is fulfilling the demands. VCI Masterbatch creates a protective layer on the surface of the metal part to prevent corrosion. VCI Masterbatch is heavy metal free, reach approved , nitrite free and also odour free. VCI provides fast and economical protection for exterior and interior surfaces.Extrusion RecommendationsThe extrusion temperature should be under 430°F. We recommend that only virgin resins be used for the production of VCI film. If necessary, modifications are made to provide for any additional properties needed such as UV, Anti-Static, etc.

VCI Masterbatch

85 Per Kilogram

We are the leading manufacturers, exporters and supplier of this products.

VCI Masterbatches

870 Per Kilogram

25 Kilogram (MOQ)

VCI Masterbatches

Get Price Quote

Our VCI Masterbatches is a Nitrite-Free anti-corrosion Masterbatch. Suitable for both ferrous and most of the non-ferrous metals, the VCI Masterbatches is in great demand. The VCI (Volatile Corrosion Inhibitor) additives are based on chemicals to release the active anticorrosion molecules from the film to protect the metal packed from corrosion. VCI Masterbatches are available with color pigment as well as without color pigment.

VCI Masterbatch

Get Price Quote

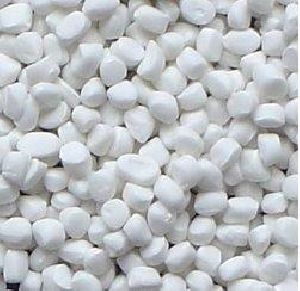

We provide VCI Masterbatch in pellet granules form which is also known as VCI masterbatches or VCI master batch used in product formation as raw materials to improve material goods property.

VCI Masterbatch

Get Price Quote

It is a nitrite free VCI Masterbatch there is impregnated with specialised VCI chemicals for corrosion protection of metals and nonmetals and is a multimetal product. This is based on SMP technology which stands for speedy moisture passivation in which 20% of the VCI is released within six hours of opening the VCI film bag and remaining 80% over a period of 15 years.

VCI Masterbatch

Get Price Quote

Spc vci masterbatch is nitrite & heavy metal free and mainly used to protect metals like mild steel, aluminum, copper, zinc, galvanized steel, & tin plate, etc.

vci master batch

Get Price Quote

vci master batch, UV Stabilizer Masterbatch, Additive Masterbatches

vci master batch

Get Price Quote

vci master batch, VCI Dehumidifier, Edge Boards, VCI PP Corrugated Flute

VCI Masterbatches

Get Price Quote

VCI Masterbatches, UV Stabilizer Masterbatches, Metallic Masterbatches

VCI Masterbatch

Get Price Quote

VCI Masterbatch, PET Straps, MS Strap, MS Strapping Strips

Volatile Corrosion Inhibitor VCI Master Batch

Get Price Quote

Volatile Corrosion Inhibitor VCI Master Batch

VCI Masterbatch

Get Price Quote

VCI Masterbatch, Vci Stretch Wrap, rubber wooden box

vci master batch

Get Price Quote

vci master batch, Plast Super 40 White Masterbatches

VCI Master Batches

Get Price Quote

VCI Master Batches

vci master batch

Get Price Quote

vci master batch

VCI Masterbatch

Get Price Quote

VCI Masterbatch, 9 Ply Corrugated Boxes, PET Strap Sealing Clips

VCI Masterbatch

Get Price Quote

VCI Masterbatch