Vegetable Cooking Oil Refinery Plant

Get Price Quote

1 Piece (MOQ)

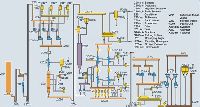

We are manufacturer, exporter & supplier of Vegetable / Cooking Oil Refinery Plant. As per the today’s market research it is being concluded that the market demands the refined edible oil with characteristics such as blend flavour and odour, clear appearance, light colour, long shelf life, suitable for frying since the crude oil obtain does contain many harmful factors like free fatty acid, sediments, gums, odoriferous compound and other impurities. GOYUM with an experience of more than 5 decades in the Edible oil industry have worked unremittingly in more than 60 countries of the world and have developed overall solutions for the Edible oil refinery needs of the customers. GOYUM provides complete solution for Vegetable / Cooking Oil Refinery Plant, capacity to design, build and supply plants from 5 - 30 TPD Batch Type & 50 - 500 TPD Continuous Type Refinery. Edible Oil Refinery Plant Process : Degumming Neutralization Efficient Removal of hydratable and non-hydratable phosphatides Improve physical stability Require low utility consumption Efficient Design Less maintenance cost Better process Bleaching Remove colouring pigments, traces of gums and metallic impurities Improve physical appearance Lower Bleaching earth consumption Uniform mixing of oil and earth Maintenance free Bleacher No dead area in Bleacher No carryover to Vacuum System Lower percentage of oil in Spent Cakes Dewaxing / Winterization Remove small quantity of solid from oil Efficient removal of waxes and saturated glycerides. Maximum heat transfer area of Crystallizer Perfect cooling profile Step cooling for complete granulation Deodorization Efficient removal of more volatile component like Free fatty acids, minor amount of colouring pigments Remove odoriferous compound Remove minor amount of colouring pigments Maximum heat transfer area Lower utility consumption Maximum Heat Recovery Zero contamination Elaborated and efficient design for the removal of fatty acid in Physical type DEO Longer shelf life of oil Very Low Maintenance.

vegetable oil processing plant

Get Price Quote

1 piece (MOQ)

SUNMAN in association with its supporting manufacturers, supported by reputed consultants and experienced oil technologists, offer the state of art equipment & plant from concept to Commissioning: Oil Seeds Handling & Oil Mills Continuous De-gumming Continuous Neutralization Continuous and Batch Bleaching Continuous and Batch Deodorizing Physical Refining Dry fractionation of Palm oil Hydrogenated Oil Plant De-Waxing Soap stock Acidulation Fat Splitting and Stearic Acid Solvent Extraction Plants

Best Deals from Vegetable Oil Processing Plant

Single Phase Vegetable Processing Plant

46,000 Per Piece

1 Piece (MOQ)

vegetable oil refinery plant

Get Price Quote

vegetable oil refinery plant

Get Price Quote

Edible Oil Refinery is the is the traditional method used in past centuries and widely practiced form of refining method by treatment of the fats and oils with an alkali solution. The free fatty acid are converted into water soluble soaps which are removed by separators. Phospholipids, carbohydrates and proteins additionally can be changed to water soluble substances with hydration. When the Alkali Refining treatment, the fats and oils area unit washed with water to get rid of residual water soluble soaps after that oil passes in vacuum Dryer to remove Moisture.

Fruits and Vegetable Preservation System by Aeolus

Get Price Quote

1 Piece(s) (MOQ)

Aeolus is most prominent supplier of 100% Made in India ozone generators. We have strong hold in Indian market in supplying Ozone based preservation systems. Vegetables and fruits have been recognized as a healthy and nutritive value food, with both a noticeable rise in consumption nowadays and greater frequency of foodborne illnesses associated with fresh produce. The microbial hazards associated with fruits and vegetables are contributed by: Microbial load of raw material Improper handling and storage Use of contaminated wash water Processing equipment, and transportation facilities Cross-contamination from other products Other foodborne illness can be attributed to complex pesticides and their preservatives like wax found on almost all fruits and vegetables. Most of the chemical pesticides are carcinogenic and indeed effect human health even at very low concentration. Disinfecting agents have widespread applications to assure safety and quality in the food industry. However, some of these agents, such as chlorine, are inefficient against some organisms, particularly at high pH or against spore-forming microbes. Furthermore, chlorine can react to form trihalomethanes, which are of concern for both human dietary safety and as environmental pollutants. Ozone is a viable alternative to traditional disinfectants. Ozone treatment has the potential to give encouraging results for some problems of the food industry like: Effective in inactivation of common and emerging pathogens, Removing toxic contaminants including chemical pesticides Leading to less loss in product quality; Adaptable to food processes Environmental friendly Hence Ozone extends the shelf life of a number of products including fruits and vegetables. And is quite efficient for such applications. Especially, ozone revealed promising results in solving the problems of the food industry like mycotoxin contamination and pesticide residues. Ozone is an effective sanitizer with great potential applications in the food industry. It decomposes into simple oxygen with no safety concerns about consumption of residual by-product. Due to its high oxidation capacity and microbial inactivation potential, ozone has prevented various kinds of microbial spoilages usually encountered in fruits and vegetables. We are capable of offering systems for vegetable & fruits disinfection and pesticide elimination for households, hotels & restaurants, community kitchens, super markets and malls, Indian Army and agriculture produce markets (APMC). We also deliver tailor made solutions with desired automation. At Aeolus, We strive to give effective and sustainable solutions to our customers. Contact Aeolus now with your requirements, we are happy to help!

mustard oil plant

Get Price Quote

vegetable oil processing plant

Get Price Quote

In batch oil refinery process or cooking oil refinery process, a measured quantity of oils is processed in sequence of neutralizing, bleaching & deodorizing.For plants capacity from 5 to 25 tons per day, batch process is recommended being low cost and easy to operate.First Stage of Refining is to Remove Free Fatty Acids(F.F.A.) wih caustic Soda Treatment called Neutralizing Process Thereafter further processed in the bleaching section under vacuum and treated with bleaching earth and activated carbon for removing colour .Finally it will be Deodorized under high vacuum and high temperature to remove the odour from the oil. The Edible obtained in a batch refinery is of good quality meeting all requirement.

vegetable oil refinery plant

5,000,000 Per Piece

Vegetable Oil Refining Plant

Get Price Quote

The inherent harmful factors for human consumption like free fatty acids (FFA), gums, sediments, odoriferous and colouring materials present in crude oils are removed completely to make the oil edible. MECTECH takes special care in all the stages and after undergoing the process of neutralisation, bleaching and deodorisation, the oil is safe and fit for human intake. Degumming / Neutralization Degumming is a process of removing phospholipids to improve its physical stability and facilitate further refining. Presence of phospholipids leads the oil colour rise in high temperature and they can also serve as precursors of oil off -flavor. Free fatty acids, pigments and other impurities are also partially removed by degumming. Mectech follows different types of degumming processes. These processes are (ie water degumming acid degumming Exzymatic degumming) being selected based on methods of processing, chemicals used and the content of phosphatides in the crude vegetable oil.

vegetable oil processing plant

Get Price Quote

we are the first to introduce advanced distillative deacidification istillative deacidification technique (Physical Refining). The innovative system totally eliminates caustic treatment with all its attendant advantages. We specialize in manufacturing pressure leaf filtration system designed for high flow rates.

vegetable oil processing plant

Get Price Quote

Filtration of oil is better than bigger oil mills giving transparent pure natural & "at a stretch convincing" appearance to the oil.Decorticator has special provision for shelling groundnut for seed purpose without breakage. Highly experienced mill operator can extract oil without cooking from some oilseeds such as rape seeds, cottonseed, sesame, sunflower, copra etc. For Groundnut, Palm kernel, Castor seed, cooking is essential.

Vegetable Oil Refining Plant

17 Per Piece

vegetable oil processing plant

Get Price Quote

The inherent harmful factors for human consumption like free fatty acids (FFA), gums, sediments, odoriferous and colouring materials present in crude oils are removed completely to make the oil edible. MECTECH takes special care in all the stages and after undergoing the process of neutralisation, bleaching and deodorisation, the oil is safe and fit for human intake.

Vegetable Oil Refining Plant

Get Price Quote

Edible oil refining plant - process of refining a) what is refining? the crude oil obtained either from expellers or solvent extraction plant contains impurities, which must be removed to make the oil edible, more palatable and stable against rancidity upon storage. the process of removing these impurities is called refining.

Vegetable Oil Refining Plant

Get Price Quote

Vegetable oil is properly refined for complete removal of waxes, gums (phosphatides) and free fatty acid. After refining. The oil is filtered from various impurities, odor and viscous pigments, thus gets a uniform color. In the plant, there can be batch refining or continuous refining as per the requirements of the applications. Incorporated with latest technology, the vegetable oil refining plant is specially designed with different processes, all integrated in a single compact unit. The plant is assembled with a bleacher, neutralizer, heat exchanger, and deodorizer, filters and high & low vacuum equipments. We are the forerunner in the industry for introducing advanced distillative deacidification technique (physical refining) in the vegetable oil refining. This is an innovative technique introduced that has the capability to totally eliminate the caustic treatment with all its attendant disadvantages. We also hold expertise in manufacturing pressure leaf filtration system that is specially engineered for flow rates. FEATURES Energy efficient operation Optimum consumption of chemicals Continuous operation with automatic loading Desolventizer toaster is used as standard equipment Integration with advanced process control system and efficient plant performance Ensure high flow rate Wet bleaching for lower earth cost Consistent product quality and output

Vegetable Oil Plants

85 Per Piece

vegetable oil refinery plant

Get Price Quote

Vegetable oil and fat resources are essential to mankind as a source of nutrient and industrial raw materials. Crude vegetable oil obtained from various oil milling units is further refined before use for edible purposes. Refined vegetable oil is a process where free fatty acids are volatized, condensed and recovered simultaneously with vacuum de-colouring operation.TINYTECH UDYOG is a prominent manufacturer and supplier of state of the art Vegetable Oil Refinery Plants in batch type units & continuous line units to get best quality refined vegetable oil. The Tinytech Vegetable Oil Refinery Plant delivers highly efficient results with excellent oil quality. It is utmost essential that the crude oil obtained from expellers and solvent plants get refined in the Vegetable Oil Refinery Plants before it is utilized directly. This purpose is fulfilled in our Vegetable Oil Refinery Plant. The Crude Vegetable Oil contains small amounts of naturally occurring materials such as proteinaceous material, free fatty acids and phosphatides. The most common method of refining oil is by reacting it with an alkali solution which neutralizes the free fatty acids and reacts with the phosphatides. These reacted products and the proteinaceous materials are then removed by centrifuge. Following alkali refining, the oil is washed with water to remove residual soap, caused by saponification of small amounts of oil. Color-producing substances within oil such as carotenoids and chlorophyll are removed by bleaching process, which employs the use of adsorbents like acid activated clays. Volatile components are removed by deodorization which is performed under high temperature and vacuum. Finally, the refined vegetable oil is filtered and is used for the further respective purposes. There are 2 refining methods in the vegetable oil refinery plant: Chemical Refining Physical Refining 1) Chemical Refining The chemical method of refining removes the Free Fatty Acids and other impurities in a chemical way by Acid-Base neutralization process. Caustic soda is used as a base for this method. The addition of Caustic Soda to the acid completes the neutralization. This results in the formation of sodium soaps and gums which are then separated by Separators & Centrifuges. The neutralized oil is subsequently bleached and deodorized.Chemical refining is most widely used method for refining all types of crude oils such as groundnut oil, soya oil, sesame oil, corn oil, castor oil, cottonseed oil sunflower oil etc. 2) Physical Refining The physical method of refining removes the Free Fatty Acids in single stage of deodorization process while the gum content from the crude oil is removed in the degumming process. Some crude oils contain non-hydratable phospholipids which are not removed by chemical refining. For that, physical refining is to be done. In physical refining, comparatively more FFA is distilled out giving a high oil refining rate with minimum oil loss. Vegetable Oil Refinery Plant - Conclusion The vegetable oil refinery plant gives color uniformity and appealing quality to the oil by removing unwanted substances and unpleasant smell from the vegetable oil. The plant and machinery consists of neutralizer, bleacher, deodorizer, cooler and various other allied equipments. Available in various capacities starting from 5TPD to 50TPD, our vegetable refinery plant finds an extensive application for almost all types of oil seeds.With decades of cumulative experience and expertise, TINYTECH UDYOG offers Vegetable Oil Refinery Plants with best technology giving pure, refined, consistent and stable finished oil at output. Get in touch with us to know more.

Vegetable Oil Refining Plant

Get Price Quote

Mectech is a leading Vegetable Oil Refining Plant manufacturerin India. Solvent extraction and distillation process produce crude Oil, which contains inherent harmful constituents like Free Fatty Acids (FFA’s), gums, sediments, odoriferous and coloring materials, phosphatides, hydrocarbons, traces of pesticides and heavy metal, that need to be refined for human consumption. Refining is the process to remove such undesired constituents from the extracted oil in the Vegetable Oil Solvent Extraction Plant, without losing out on the useful factors or affecting the composition.

vegetable oil refinery plant

40 Per Piece