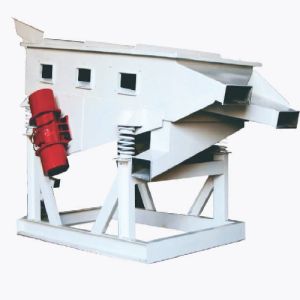

Vibrating Screen Machine

50,000 - 100,000 Per Piece

1 Piece (MOQ)

We are one of the leading Manufacturers, Suppliers, Distributors of this highly commendable range of Vibrating Screen Vibrating Screen has come out with a most advance design of screens for grading of fine, wet and difficult to screen materials. The screens works on the principle of gyratory motion. The unique features of this type of sieve is its high capacity using minimum space and less power. The screen has specially designed multi-directional vibration system which prevents blinding of sieves. The material to be screened is fed from the top and collected simultaneously from outlets of different decks. These screens can handle wide range of materials such as heavy, light, dry, wet, coarse or fine. The company manufactures various sizes to suit individual requirement in M S and S S construction.. Vibratory motion is the most effective method for screening. It causes 100% rotary motion and causes dispersion stirring & stratification of material to be sifted. Feed material constantly flows in Horizontal motion along a loop pattern on Vibro screen surface."EXCEL" Vibro screen provides optimum screening & assures maximum feed-rate & efficiency The vibrating screen is an important part of the incepting steps in any industry. The companies which require the processes or have the steps involved in the separation, sizing, and sorting the various materials and their parts out have the operations done with the good quality screens. Using the screens These screens are also called the vibrating sieves. The sieves we use regularly at home is in the ground level separation .i.e. small scale while the vibrating screen is the one which is used as a part of the initial processing of the raw materials in any industries. The cement industries, powder industries, companies that make spices, which produce fillers for food products etc. should have the correct mesh size to follow for the particles which are separated by these screens. Shape size make etc. These are availed in huge flat, basket shaped, cylindrical, and curved or even the irregular format of shape. The size would however vary from the products used to separate. The basic principle behind such separation is the size of the mesh and the gravitational force. The dimensions decide the shape and kind of products to be separated.These screens are highly durable and tough made from the metals that are hard enough for the usage and corrosion free too. To avoid spillages as well there are mechanisms provided in the screen feeders.

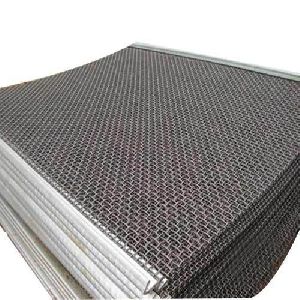

vibrating screen mesh

Get Price Quote

Best Deals from Vibrating Wire Mesh Screen

Vibrating Wire Mesh Screen

Get Price Quote

We are connected with well-known transport providers to make sure the distribution of deliveries is done out without a problem and on time. Our organization is highly concerned towards providing excellent quality products to the customers and thus check them at all stages. Features : High Tensile Strength Can withstand tough Conditions Resistance to corrosion Resistance against wear & tear Applications : Metallurgy industry Coal industry Mineral industry Agriculture industry

crimped wire mesh vibrating screens

85 Per Kilogram

vibrating screen mesh

120 Per Kilogram

1 Ton (MOQ)

Oblong Vibrating Screen Mesh

110 Per Kilogram

500 Kilogram (MOQ)

Vibrating Screen Wire Mesh

Get Price Quote

100 Piece (MOQ)

Description Frequency Drives Soft Starters Contactors Relays / Add On Block MCCB / MPCB Panel Accessories

Galvanized Crimped Wire Mesh Vibrating Screen

Get Price Quote

We offer Galvanized Crimped Wire Mesh Vibrating Screen. Vibrating Screen A wide range of Vibrating Screen, Wire Mesh Vibrating Screen and High Frequency Vibrating Screen made of high grade metals is available to fulfill varied requirements of industries. We have screens in different materials, wire diameters, mesh opening, dimensions and weaving patterns that can be chosen as per the specific application and nature of raw materials. Extensively used for sizing, screening, shifting, grading, separating, scalping and washing, these screens have high tensile strength, excellent adaptability to work under adverse conditions and high resistance against corrosion and chemicals.

Vibrating Screen Wire Mesh

Get Price Quote

Vibrator Screening Wire Mesh

Get Price Quote

10 Piece (MOQ)

Vibrating Screen Wire Mesh

Get Price Quote

Coarse type of wire mesh are normally used for making screen for vibrating machines screen for vibrating machines. Screens are woven accurately to the mesh size with appropriate wire or rod to meet specific requirements. Screens are offered in spring steel, mild steel, galvanized steel and stainless steel to suit particular applications. In vibratory finishing, energy in the form of vibratory forces is transformed by the machine's drive system into a mass of loose media and then into the parts. The entire load is in motion at the same time so that the media act against the parts throughout the complete mass. Basic elements of the system include the machine, the media, and the compound and/or water solution. Selection of each depends primarily on the parts being run - that is, the type of parts: size, shape, and condition; and the work to be accomplished.

VS 1854 Wire Mesh Design Vibrating Screen

Get Price Quote

1 piece (MOQ)

Vibrator Mesh Jali Fixing Ring

Get Price Quote

vibrating screen mesh

145 Per Square Feet

20 Square Feet (MOQ)

Vibrating Wire Mesh Screen

200 - 350 Per square feet

100 square feet (MOQ)

vibrating screen mesh

Get Price Quote

Vibrating & Heavy Industrial screens are manufactured with clamps on either sides which are made by Spring Steel, High Carbon Steel, Stainless Steel, Galvanized Iron & Mild Steel Wire as per client's required sizes and are manufactured with providing High tensile abrasion resistant being mainly used in mines & quarry industries, coal mines, foundries, heat treatment & waste management etc. These Heavy / Vibrating Screens are also generally used for screening of various products & sizing or processing heavy abrasive materials like ores, crushed stones, sand, gravel coal etc. Available as per customers' requirements and Specifications.

vibrating screen mesh

Get Price Quote

Wire Mesh Manufacturers in DelhiSince 2009, Damodar Perforators are well-recognized Wire Mesh Manufacturers & Suppliers in Delhi. We attained proficiency in proffering our Valued Patrons with Steel woven wire mesh, which is highly demanded in the market due to its supreme quality and specified standard. Our manufactured wire mesh is highly acclaimed by our customers.Reliable QualityWe are widely admired for our manufactured Wire Mesh because our experts manufacture it as per the supreme quality norms and standards. We produce it by utilizing the prime quality of raw materials and revolutionary methods. Wire mesh that is manufactured by us is highly acclaimed for its corrosion and abrasion resistance, dimensional veracity, and low maintenance.Customization FacilitatedAlong with the prime quality products, we believe to serve gratification to our precious customers. So, to provide them contentment, we offer customization for the betterment of products as per their stipulations. Our experienced professionals acquire advanced technologies to meet the requirements of our customers. Before dispatching our manufactured products to customers, the products pass through various quality parameters to ensure the flawlessness in its quality.High-grade QualityDamodar Perforators are recognized to serve an optimum range of Vibrating Wire Mesh Screen in Delhi to the Patrons. Our experienced and skillful team of experts manufacture the vibrating wire mesh screen by utilizing the highly revolutionary and advanced technologies to produce an upgraded product as per the Patron’s requisites.Key FeaturesOur manufactured vibrating wire mesh screen is receiving more demand with high appraisal regarding its premium quality. It is highly recommended by customers due to its main highlights that include its superior finish, long life expectancy, High tensile strength, robust construction, corrosion resistance finish and dimensional flawlessness. Highly ApplicableVibrating Wire Mesh Screen is highly applicable in a vast array of applications. Due to its highly durable quality, it is highly recommended in the Industrial area. It is utilized in the waste management industry, Food processing industry, Agriculture industry, mine and quarry industry, water treatment industry, coal preparation Industry, ore grading industry, etc.

Vibrating Wire Mesh Screen

2,700 Per Piece

3 Piece(s) (MOQ)

We are counted among the best industrial vibrating screen manufacturers in india. An ample range of highly efficient circular vibrating screen is provided by us. We have firmly positioned ourselves as one of the preeminent vibrating screen manufacturers and vibratory screen suppliers, based in India. Our circular vibrating screen is available in various sizes and dimensions and can be customized as per the requisite of the client. This circular vibrating screen is manufactured from the high grade quality raw materials to ensure their durability and reliability. They provide excellent performance even in tough and extreme conditions. Vibrating Screen is also known as Wire cloth, crusher screen. We produce vibrating screen as per customer specifications with clamps and edge preparation and this has put us in the league of leading industrial vibrating screen manufacturers in india. » Range Of Production : 0.5mm to 150mm » Wire Size : 0.3mm to 16mm » Material : Spring Steel, Stainless Steel, Mild Steel, Copper, Brass, e.t.c. » EEdge Preparation : K-1,K-2,K-3,K-4,K-5,K-6,K-7 S, U e.t.c. » Type : Double crimp, intermediate, dovex, lock crimp, e.t.c.,

Vibrating Screening Machine

Get Price Quote

a) Single/Double Deck Vibrating Screens: Single and double-deck vibrating screening machines are designed for screening various materials in powder form. These machines are simple and robust in construction. Screen sizes are available of 1500 x 600mm, 1800mm x 800mm, and 2500mm x 800mm. Special sizes as per client requirements are also made available. The vibrating screens are also available with a magnetic system to remove fine iron and contamination from products like chemicals, pharmaceuticals and food products, etc. b) Multi-Deck Vibrating Screens: These are used for much superior, faster, and more accurate sizing, splitting, or correcting. The vibrating screening machine is designed for the sizing of minerals, ceramics, refractories, and other powders. The principle on which our multi-form grader operates is equally adaptable for the handling of many ceramic products as well! The unit is more than “Just a screen”; it is a precision tool for producing accurate grades, not merely a rough grouping of sizes. It is economical in regards to power and space; screen life is long; and low maintenance. It is adaptable to a wide variety of materials and conditions. Multi-deck vibrating screens are available in different models. Model Dimension HP JVS-01 5′ X 24 “ 1 HP JVS-02 6′ X 32 “ 1 HP JVS-03 8′ X 32 “ 1 HP Salient Features: · Long service life and extremely quiet because of maintenance-free vibrating elements.· The electricity consumed to screen every ton of material is low.· The circular vibrating screen has a simple structure so dismantling and changing the screen surface is very convenient. Our Vibrating Screen Machine is used for: · Chemicals· Pharmaceuticals· Aluminium Fluoride· Spices· Flour· Semolina· Turmeric Powder· Chili Powder· Mineral Garnet· Zircon· Medicines· Bulk Drug· Plastic· Rotomoulding Machine· Refractories· Wood Chips· Ceramic Pulp· Paper Mill· Packaging Line

Vibrating Wire Mesh Screen

2,000 Per pieces

1 Roll (MOQ)

available in all sizes according to customers specifications