Vibrating Conveyor

120,000 Per Piece

5 Piece (MOQ)

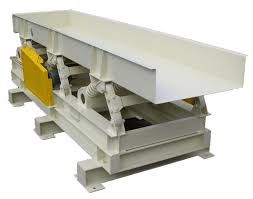

Owing to our vast manufacturing facilities, we are able to offer a diverse and extensive range of Vibrating Conveyor. The offered range is appreciated in market for their innovative technology, easy operations, offering pure mineral water, long service life and easy installation. In addition to this, the offered range is utilized in cement plants, coal mines, renewable energy plants, sugar factories and paper industry.Features: Robust construction High load carrying capacity Energy efficient

Vibrating Conveyor

100,000 Per Piece

1 Piece(s) (MOQ)

Best Deals from Vibratory Conveyor

Vibrating Conveyor

Get Price Quote

1 Piece (MOQ)

Vibrating Conveyors

Get Price Quote

Being one of the most prominent Manufacturers, Exporters and Suppliers in Chennai, Tamil Nadu, we produce the high-end Vibrating Conveyer with latest technology. This Vibrating Conveyer is characterized by the low horsepower essential and high volumes of material. We are providing this Vibrating Conveyer with a flexible balanced design which facilitates exceedingly polish conveyor to handle it gently. Advantages Of Vibrating Conveyor Levels and orients material as it is conveyed, reducing surges to downstream equipmentMoves high volumes of material with low horsepower requirementsCounter balanced design provides an extremely smooth running conveyor with reduced foundation and support structure requirementsBuilt in 10 foot long sections which are bolted together to make up a conveyor of the required lengthOdd length sections are available for use at the ends of the conveyor when the length is not a multiple of 10 feet

Vibrating Conveyor

Get Price Quote

Vibratory Conveyor

Get Price Quote

1 Piece (MOQ)

Vibrating Conveyors

Get Price Quote

Five Deck Vibrating Conveyor

Get Price Quote

vibratory conveyors

Get Price Quote

We use packaging materials that are industrial grade, and non-toxic. The labels on packages are tamper and smudge proof. We have stringent packaging related policies. Superior transportation facilities, efficient workforce and on-time delivery of the products make us stand out from the crowd.

Vibrating Conveyor

Get Price Quote

Vibrating Conveyor

Get Price Quote

We provide a large assortment of high efficacy Vibratory Feeder, which is used in various industries for specific applications. We are well-known as one of the prominent Vibratory Linear Feeders Manufacturers and Suppliers based in India. Our Vibratory Feeder is manufactured from the optimum quality raw materials to add durability and performance. Vibratory Feeder offered by us is available in various sizes and dimensions as per the need of the clients for Vibratory Bowl Feeding.

vibratory conveyors

Get Price Quote

vibratory conveyors

Get Price Quote

With Electro Magnetic / Motorized Type Vibratory Conveyors are used in almost all the industries to convey the product in industries like dry aggregates, foods, fruits, vegetables, rubber, gun powder, abrasive, explosive materials, foundry sand, chemicals, ceramics, metal parts, stamping, casting, Tobacco. Chemicals: Conveying of scrap plastic pellets of fiberglass in reprocessing system, conveying and scalping foreign matter from chemicals at bag dump stations. Food: Conveying of multiple ingredients for blending while conveying. Transfer of bulk ingredients from weight hopper to mixer, conveying freeze-dried of spray dried food product of storage area. Foundry: Conveying sand in primary and sand processing system, conveying small castingfrom shake out areas, conveying scrap to charging area. Automotive: Parts conveying in blanking and punching operations. Conveying parts to platingoperation, flux conveying in automatic welding machines Concrete: Conveying dry ingredients (cement, sand, gravel) to weigh batch hoppers. Distributionof Steel reinforcing particles in concrete botching and mixing operations. Steel: Mill scale conveying units under strip and bar operations.

Vibratory Trap Door Conveyor

Get Price Quote

Vibratory Conveyors are of mass balanced design.Simple, robust and most efficient conveying equipment. Depending on layout, vibes are designed, viz., Normal, Semi compressed, Fully compressed, Inverted etc. Built in features are linked to application. Can be fitted with Pneumatic trap doors or Metal detecting head etc.

Vibratory Conveyor

Get Price Quote

We manufacture and supply all types of conveyors for assembly and packaging, which are suitable to clients’ wide requirements such as assembly of light engineering items, packing of pharmaceutical products, hardware, electronic goods etc. Our exclusive range of conveyors includes belt conveyors, gravity roller conveyors, powered roller conveyors, metal slat conveyors, chain conveyors, vibrating conveyors, screw conveyors, etc. The company has designed special conveyors like slat conveyors for two wheeler industries, which are available at market leading prices.

Vibrating Conveyor

Get Price Quote

Vibrating conveyors are used to move materials from one place to another and can be individually tailored for a wide range of process applications with coil spring or contour composite spring components. Standard and custom designs are readily available to suit the application. Common design options include: Dust tight covers with quick release clamps, food grade construction, low profile, dynamic balancing, specialty trough finishes, abrasion resistant liners, magnetic separation, metal detection, air classification, cable suspension, high temperature designs, etc.

Vibratory Conveyor

Get Price Quote

Sometimes while feeding the dry bulk material to other equipment for further processing or conveying, the material may not move due to the less friction with the surface of the feeder and among the particles. A vibratory feeder in such cases is required to make the material move forward over an incline by producing a vibration effect. Here the material itself is the most important factor. To be fed conveyed properly it should have a high friction factor on steel (of which the feeder is manufactured) as well as a high internal friction factor so that conveying action is transmitted through its entire depth. Vibratory Feeders are essentially directional-throw units which consist of a spring-supported horizontal pan vibrated by a direct connected eccentric arm, rotating eccentric weights, an electromagnet or a pneumatic or hydraulic cylinder. The motion imparted to the material particles may vary, but its purpose is to throw the material upward and forward so that it will travel along the conveyor path in a series of short hops.

Vibratory Conveyor

Get Price Quote

The motorised vibratory conveyor consists of a horizontal tray made of mild steel or stainless steel. The horizontal tray is fixed to the frame, The vibrations are provided by two special unbalance motors fixed on either sides of the tray. The complete assembly of tray with motors rest on a set of coil springs so that, no vibrations are transmitted to the stand and ground. As the Motor starts, the vibration sets in motion. Controlling of vibrations gives the controlled flow of the material. The housing of the motor is in totally enclosed design to prevent dusting. The motor operates at 400440v 3phase A.C. system at 1440 RPM. Motorised vibrating conveyor can be supplied in different capacities depending up on type of the material required to be handled.

Vibratory Conveyor

Get Price Quote

As an expert Bowl Feeder Manufacturer, we bring forth Vibratory Bowl Feeders that are manufactured and designed specifically for handling materials that need high feeding rate. Our top quality Vibratory Bowl Feeders ensure maximum efficiency and low maintenance as they possess various advanced features. The company also offers total design, tooling, and manufacturing services for customized Vibratory Bowl Feeders. We manufacture bowl feeders for press machines, bowl feeders for capping machines, bowl feeders for SPM’s, bowl feeders for bearings, bowl feeders for powder parts, bowl feeder for sizing presses, bowl feeders for pad printing machines, bowl feeders for drilling spm, bowl feeders for packaging machines, bowl feeders for automotive components, bowl feeders for automobile components, bowl feeder for bearing components, bowl feeders for forging components, bowl feeders for pen components, bowl feeders for shaving blades, bowl feeders for assembly machines, bowl feeders for syringes, bowl feeders for needles. We have carved a niche as one of the leading Premier Bowl Feeders Manufacturers and Suppliers in India.

Vibrating Conveyors

Get Price Quote

Capacity: Capacity up to 500 TPH and length upto 60 Meter for all materials including fine dust, big lumps, abrasive and hot materials. It can carry materials downward, horizontally and upward as well upto 10 inclination. The conveyors can carry four different materials in the same conveyor and also can carry out screening while conveying. It can carry materials up to 1200°C and also under pressure, vacuum or freezing conditions.