Water Separator

Get Price Quote

5 Piece (MOQ)

Water Treatment Plant Spare Parts

Get Price Quote

Best Deals from Water Treatment Accessories

FL-250 Dual Intensity Self Cleaning Rainwater Filters

11,653 Per Piece

5 Piece (MOQ)

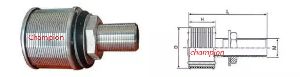

Wedge Wire Screen Filter Nozzle

33 Per Piece

150 Dozen (MOQ)

champion wedge wire screen filter nozzle very good slot width precision. high mechanical load capacity no form closure connection that would allow vibration of the profiled bars. v-shaped wire around the twin tube water cap for metallurgical industry automated welding process for high-precision manufacturing perfectly adjusted screen basket profiles available for all screens surface finishing as required. made in ss304-316-316l,monel,hastalloy,titanium to suit application needs.

CWS Water Separator

Get Price Quote

1 Piece (MOQ)

Sub Micron Filters

12,000 - 16,000 Per Piece

1 Piece (MOQ)

Salient Features: Automatic drain valve Particles up to 0.01 microns are filtered. Very low pressure drop, 1 PSI for dry media and 2-3 PSI for wet media Status indicator Different coalescer grade for various applications Maximum oil carries over of 0.008 PPM w/w Application: Painting CNC Garments Textiles Instrumentation Automobiles Pharma Food industry Packaging

Multi Rake Bar Screen

100,000 - 300,000 Per Piece

1 Set (MOQ)

Alkaline Water Filter Jug

850 - 4,500 Per Piece

12 Piece (MOQ)

Mechanical Screen

Get Price Quote

5 Piece (MOQ)

1000kl ETP Storage Tank

Get Price Quote

Thermoplastic ETP Tanks for Effluent Treatment

Get Price Quote

Since the last 25 years, we have been the leading manufacturer s of etp tanks made in thermoplastic or composite materials. Our etp tanks are made from 100% corrosion resistant thermoplastic material and thus has an extremely long life. These etp tanks are made on our state-of-the-art wegener butt fusion welding machine 4m span, only machine of its kind in india and the latest technology available in the world for plastic fabrication. Weld strengths obtained using butt fusion welding has upto 99% strength of parent material. With our highly qualified and technically sound team, state of the art infrastructure, sophisticated manufacturing facility and sourcing of quality raw materials, we are able to fabricate quality products as per international dvs standards. Our vast experience helps us design the system to be most cost efficient. Etp tanks can be made in any size and any shape: rectangular, cylindrical, conical, slant bottom, etc.

Micron Filter

25 - 390 Per piece

1 Box (MOQ)

Bamboo Hot Water Treatment Tank

Get Price Quote

1 Piece (MOQ)

The “Bamboo Hot Water Treatment Tank” by Prashant Bamboo Machines is a specialized equipment designed for the thermal treatment of bamboo to enhance its durability, strength, and resistance to pests and decay. Key Features: 1. Thermal Treatment Capability: The hot water treatment tank is capable of subjecting bamboo to controlled high-temperature water immersion. This process effectively modifies the bamboo’s physical and chemical properties, resulting in improved durability and performance. 2. Optimal Temperature and Time Control: The machine offers precise control over the temperature and duration of the hot water treatment. This ensures that the bamboo is exposed to the ideal conditions for the desired treatment outcome, achieving optimal results consistently. 3. Large Capacity: The treatment tank has a generous capacity to accommodate a significant quantity of bamboo at a time. This makes it suitable for both small-scale and large-scale bamboo treatment operations, providing efficiency and productivity. 4. Safety Features: The machine incorporates safety features to ensure the well-being of operators and protect against potential hazards. It includes temperature monitoring and control mechanisms, safety valves, and robust construction to ensure safe and reliable operation. 5. Durable Construction: The hot water treatment tank is built with durable materials that can withstand the high temperatures and water immersion. It is designed to withstand regular use and provide long-term performance. The Prashant Bamboo Machines Bamboo Hot Water Treatment Tank is an essential tool for bamboo processing industries, ensuring the enhancement of bamboo’s properties for various applications. Contact Prashant Bamboo Machines to learn more about how this machine can optimize your bamboo treatment process, improve product quality, and increase the overall value of your bamboo products.

SS Grease Trap

8,500 Per Piece

1 Piece (MOQ)

Grease Traps come in a range of sizes relative Specified Equipment The Wyuna Sep WSG series Grease traps proposed will be in accordance with client’s or project’s provided. This type of Grease Traps has been successfully used in a wide range of applications e.g Restaurants, Ice Cream Shops, Coffee Shops, Cafeterias, Deli’s, Bucher Shops,Bakeries, Convenience Stores, Motels, Hotels, Schools,Day Cares, etc. Installation Simplicity Wyuna Sep has supplied many separator systems forto the through-put of water needed. They are designed to fit under standard sized work benches. If however space is an issue all our units are manufactured from rust free stainless steel and can be located externally.Features: High Performance: WyunaSep uses flow configuration in such a way that it splits, dampens, and elongates the incoming flow of kitchen wastewater. This means there is not short-circuiting or channeling of the flow within the system. By preventing turbulence, eliminating re-mixing and providing minimum residence time per unit volume. WyunaSep Grease Trap creates an optimal environment for in-kitchen grease separation. Installation Flexibility: The unique flow pattern in the Grease Trap allowed WyunaSep to design a system that easily fits in confined spaces typically available in commercial kitchen. Additionally, the dimension of the Grease Trap fall well within the footprint of most competitive conventional grease traps. WyunaSep has a system available to replace that rusted metal trap regardless of where it is currently installed –under sink, next to sink or in-floor. Built to Last: WyunaSep Grease Trap is constructed of SS 316/304 that were specially chosen for long life Under harsh conditions. Gone are the days when a commercial kitchen operation has to replace a leaky, rusted, broken metal / concrete traps every two to three years. Additional Information: Delivery Time: 2 weeks

Mechanical Bar Screen

850,000 Per Piece

1 Piece (MOQ)

Micron Cartridge Filter

Get Price Quote

1 Piece (MOQ)

Water Separator Head

2,000 Per Piece

1 Piece (MOQ)

Water Treatment Plant Parts

1,800 Per pieces

1 pieces (MOQ)

Providing all global water solutions, Bonnafide Chemicals is offering a wide range of Water Treatment Plant Spares. The wide range of Water Treatment Plant Spares is designed for water well, pressure booster, irrigation, reverse osmosis storage, thermal expansion, hydraulic heating, fire prevention and water hammer arresting applications.

Bar Screen

150,000 - 700,000 Per Piece

1 Piece (MOQ)

Inline Micron Filter

950 - 1,200 Per Piece

1 Piece (MOQ)

LABIN Make IMF use for to Remove dust particles up to 0.5 micron from inert gases

Marine Oily Water Separator

Get Price Quote

Multi Rake Screen

200,000 Per Piece

1 Piece (MOQ)

Mist Evaporator .

Get Price Quote

1 Piece (MOQ)

Square Tramp Oil Separator

Get Price Quote

1 Unit (MOQ)

Mechanical Bar Screen

Get Price Quote

1 Piece (MOQ)

Rake screens of various measurements are made of stainless steel AISI 304 or AISI 316 on customer demand. Measurements of the rake screens are chosen relying upon required flow rate, wastewater arrangement and measurements of the channels. The rake screen is a separating mesh comprising of bars introduced into a frame. The bars are produced using primary shapes with a tear drop formed cross segment that improves stream attributes of the filtering mesh. The screen’s filtering mesh can also be made of rectangular or round profile bars. Bar dispersing in the filtering mesh can change from 5 – 100mm for normal hardware or can be changed exclusively. The rectangular edge comprises of two longitudinal sheets associated by cross shafts. The covered hardened steel chains can be moved along polymer guides installed on the longitudinal sheets of the screen. Chain strain is movable. Cross rakes are introduced on the chains for cleaning of the filtering mesh. Chains and rakes are impelled by shaft rotation with drive sprockets situated in the screen top segment. The shaft is driven by a motor. At the screen base, the chain is moved along a pilot slider made of a wear safe polymer material. In this way, there are no pivoting parts in the lowered segment of the screen. The screen is introduced onto a hub of an extraordinary turning prop mounted on the wall of the channel or onto unique stage affixed in the channel while the actual screen can be lifted over the channel for upkeep. In the event that there is an absence of room in a short station without probability of screen lifting, an extraordinary adaptive stage is utilized Operating Principal The rake screen gathers and eliminates solids from wastewater that bigger than bar separating. The solids are regularly taken off from the sifting network by the rake moving them to the top edge of the edge. The solids are then eliminated from the rake by methods for a kicker and dispatched along the gravity slide onto a carrier or into squander container. The screen operation periodicity depends on the chosen equipment automation scheme and defined by technological commission results. Advantages of Bar Screen: Protection from mechanical and pressure-driven over-burdens because of high tensile design in correlation with different kinds of mechanized screens High hydraulic efficiency is achieved by using tear-shaped bars that cause a pressure gradient to the mesh and across the bar spacing The tear molded profile also shields the screen from waste sticking inside the filtering mesh. By utilizing this plan, such blockages can be eliminated by rakes, permitting the screen work uninhibitedly; High dependability, accomplished by the shortfall of the turning parts in the submersible part Submersible parts like packaging, bars, chains and rakes are made of tempered steel to improve consumption obstruction in forceful conditions of wastewater; Improved ergonomics: the practicality of the screen because of openness of the principle units inactivity and screen lifting without demounting. Automation : Screen automation is possible as per various boundaries: Timespan. Wastewater level contrast upstream and downstream of the screen. Any modified program. Alert frameworks are accommodated the typical activity sign, the crisis stops, the wastewater high level in the channel and others. It is conceivable to move gear status information to a more significant level automated process control framework relying upon the customer’s necessities. The screen is provided with a security device jet lever to evade harm to the screen, for example, chain extending or breaking. The security gadget and stops the screen activity in case of any jam or mechanical hindrance to the chain development. Light and sound alerts turn on all the while when the safety device activates. The screens along with a conveyer, compacting press and slide doors are remembered for an elite complex for mechanical wastewater treatment. Outfitting the control system with programmable modules makes it conceivable to coordinate complex sub systems into one system with a common control centre and remote dispatching.

Adaptor And Plastic Filter Nozzle

Get Price Quote

With very rich years of working experience and sincerity, we are offering best and most perfect quality assortments of Adaptor and Nozzle. These strainers are contrived and designed by our qualified engineers with the use of best quality machines and skills. They are best in class and tested to keep them as per required level. These collections are cost effective in rates. Features: Metal finished Easy to install Best in class Specifications:

Micron Filter

25,000 - 200,000 Per Piece

1 Piece (MOQ)

Oil And Grease Trap

Get Price Quote

1 Piece (MOQ)

Wastewater Pump

Get Price Quote

Design End suction top discharge Mounting: Horizontal Stage: Single Casing with hand hole inspection cover mechanical seal/ gland packing large free passage up to 200 mm Grease lubricated antifriction bearing Application Municipal raw sewage transfer Sewage treatment plants Effluent treatment plants Dirty water in industry Sugar mills Special features / product benefits Mounting: Vertical Delivery flange orientation change possible Bush bearing Technical data Qmax: 8000 m3/hr Hmax: 70 m Temperature: up to 70°C Delivery Size: DN 50 – DN 800

Wastewater Pump

Get Price Quote

Drum Thickener, Flocculation Tank, Belt Filter Press, Mechanical Fine Screen