Water Tube Boiler

Get Price Quote

1 Piece (MOQ)

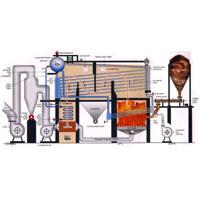

Water Tube Boilers has unique design with ample water holding capacity, tall furnace for complete combustion of fuel particles within the furnace zone. High Pressure Boilers with highly advance technology enables the most efficient combustion of fuel as well as makes the boiler highly fuel flexible. Water circulation through the boiler is also either natural circulation because density distinction or by forced circulation.High Pressure Boilers has wide applications in wide range of industries like paper, textiles, chemicals, distilleries, rubber solvent, pharmaceuticals, food processing etc. High Pressure Boilers operates with different type of furnaces like, FBC, traveling grate, pulsating grate, dumping grate etc.Features : High Thermal efficiency Fluidized bed combustion, Travelling Grate & Dumping Grate for high ash/low grade fuels as per fuel requirement Membrane panel construction for fuels with low ash fusion temperatures Clean boiler house environment through enclosed and mechanized fuel feeding and ash retrieval system Automatic fuel feed control to ensure steady the steam flow Easy of maintenance : Total accessibility to pressure parts and furnace from both inside and outside Quick and easy start ups and relighting made easy

Water Tube Steam Boiler

5,000,000 Per Units

Best Deals from Water Tube Boiler

Water Tube Boiler

Get Price Quote

The Water Tube Boiler is marked by the quality that it offers. The use of premium quality materials in the manufacturing makes the Water Tube Steam Boiler is a long lasting one. Developed in the latest upgraded technology, the Water Tube Steam Boiler is totally safe to be used. We are counted among the Flexible Water Tube Boiler Manufacturers in India.

Single Drum Water Tube Boiler

Get Price Quote

The material that is used for the production complies with high quality standards and quality-proved by the experts. Also, we make sure that the raw material is sourced from the trusted places. As we are supported by wide distribution network and fastest transportation facilities, we deliver the orders on time. Our single drum water tube boiler is available with a quality warranty of 12months.

Multi Fuel Water Tube Boiler

Get Price Quote

Composite type boiler is combination of smoke tube & water tube design. This construction gives benefits of both types of designs. Membrane panel type water tube structure is attached to smoke tube type shell. Furnace is made of channels & beams which is covered by refractory bricks & fire bricks. Multiple fuel feeding doors & ash doors are provided as per capacity of Boiler. ID and FD fans are provided for maintaining balanced draughtAll type of grates like fixed grate, Fluidized bed, Controlled air combustion, Dumping grate, Pulsating grate, Travelling grate, chain grate can be fitted according to fuel availability & capacity of Boiler. Product Range : Capacity - 2000 kg/hr 15,000 kg/hr Pressure - 10 kg/cm2 to 25 kg/cm2(g) Fuels - Solid fuels such as Wood, Coal, Briquettes, Sawdust, Bagasse, rice husk, coffee husk, palm shell, Groundnut shell, coconut shell etc. Special Features : These Boilers are multifuel type boilers. The firing system can be modified for burning multiple fuels. Multiple doors are available for manual fuel feeding & ash handling. Easy for installation. Most customized type design. Accessories like Air pre heater, economiser, water pre heater can be provide to enhance output and efficiency. The furnace is also external to the boiler to enable combustion of high moisture agro-fuels like bagasse. Particulate emission controlled using Multicyclone Dust Collectors, bag filters and ESP.

water tube type boiler

Get Price Quote

Water Tube Coil Type Boiler

Get Price Quote

REVOSTEAM is the conventional forced circulation type water tube coil type boiler incorporating the unique principle of combustion known as ‘Reverse Flow’. This flow of flue gases enhances the combustion efficiency and also allows a high rate of heat release to the surrounding water coil. It can be offered in both IBR and Non-IBR designs

Water Tube Cum Smoke tube Boilers

600,000 - 15,000,000 Per Set

1 Set(s) (MOQ)

We are offering water tube cum smoke tube boilers are most suitable for steam generations upto 1214 tph. They give the advantage of water tube boiler such as higher efficiency, higher heat transfer areas, higher combustion area and advantages of smoke tube boilers like higher water hold-up and good response to variations in steam pressure. We offer upto 1 mw back-pressure steam based power generation with these boilers. Its economical, if you are generating power from the steam you are consuming in process. Co-generation is a great opportunity for industries, fighting to reduce their operating costs. We can help you with economical solutions.

Water Tube Boiler

Get Price Quote

We have innovative and extensive range of Water Tube Boiler available with us at the market leading price. Our Water Tube Boiler can handle different capacities and pressure specified by the customers. We have expertise in supplying bulk orders of Water Tube Boiler. Our supplying unit is well equipped to examine the quality of the Water Tube Boiler before the final dispatch. Suitable For Multiple Fuel Options Coal Husk Wood Biomass gas

water tube boilers

Get Price Quote

We are a trusted name in manufacturing Water Tube Boilers & all the pressure parts such as main Steam Drum / Water Drum / Furnace Tubes / Super Heater Tubes / Economizer Tubes / Boiler Headers / Super Heater Header / Atemprator Header & Economizer Header Our concern manufactures all most every pressure part of any make / model. We can also customize these products in specifications required by the clients.

Water Tube Boiler

Get Price Quote

Smoke Tube water wall Membaren Type Steam Boiler

1,000,000 Per Piece

J.D.ENGINEERS is manufactured with Water cum Smoke Tube design that makes it doubly advantageous. It provides a water-cooled furnace which is paneled to prevent heat loss. The tall shape of the furnace provides sufficient residence time for complete combustion of fines & volatiles and reduces the carry over. The vertical configuration of evaporative tubes enables better circulation of steam. A boiler quality strip provided in between the water wall tubes makes the furnaces leak-proof The large sized drum makes available greater steam-water interface area thus ensuring Dry Steam. Features Optimum thermal efficiency due to higher combustion volume & large grate area. Minimal radiation losses due to water membrane wall mounted on furnace. Minimum maintenance required due to less refractory work. Better response to fluctuating steam load as large water & steam holding capacity. Dry steam due to large steam to water interface area. MULTI -FUEL OPTIONS Coal, lignite, wood and all type of agro waste. FIRING OPTIONS Manual firing FBC - Over bed feeding FBC - Under bed feeding Pneumatic firing Dumping grate Pulsating grate Reciprocating grate Travelling grate

Drum Water Tube Boiler

Get Price Quote

Rakhoh enterprises is one of the leading manufacturers and suppliers of drum water tube boiler. We have an expertise in the domain of manufacturing of drum water tube boiler, owing to our 17 years of experience. We design our product as per the latest amendments of the ibr code and other internationally recognized codes and are provided with more than all mandatory safety requirements. Suitable to burn different type of fuels : bagassehuskwood chipsbricketscoal benefits : less refractory work, hence less maintenance.high overall efficiency combined with reliable operation achieved through accurate computerized thermal and mechanical designs of boiler.provided with grates like fixed grate/dumping grate/pulsating grate/travelling grate/fbc grates.quick steam generation and can take care of changing requirement of the steam in the process.provided with accessories like super heater, economizer, air pre-heater, de-aerator tank, multi cyclone dust collector etc. As per requirement for better performance of the boiler.longer life of super heater as it is placed behind screen tubes in the furnace.multi-passes in convection bank make the boiler efficient and more economical.

Water Tube Boiler

Get Price Quote

A water-tube boiler is a type of boiler in which water circulates in tubes heated externally by the fire. Water-tube boilers are generally used for high-pressure boilers. Fuel is burned inside the furnace, creating hot gas which heats up water in the steam-generating tubes. In smaller boilers, additional generating tubes are separate in the furnace, while larger utility boilers rely on the water-filled tubes that make up the walls of the furnace to generate steam. The heated water then rises into the steam drum. Here, saturated steam is drawn off the top of the drum. In some services, the steam will reenter the furnace in through a superheater in order to become superheated. Superheated steam is used in driving turbines. Since water droplets can severely damage turbine blades, steam is superheated in order to ensure that there is no water entrained in the steam. Cool water at the bottom of the steam drum returns to the feedwater drum via large-bore 'downcomer tubes', where it helps pre-heat the feedwater supply. The feedwater is supplied to the steam drum and the downcomers supply water to the bottom of the waterwalls. To increase the economy of the boiler, the exhaust gases are also used to pre-heat the air blown into the furnace and warm the feedwater supply. Water tube boiler is sub-classified as –1. Bi-drum Boiler ( It has two drums )2. Single drum Boiler ( It has only one drum )

Water Tube Combo Boiler

1,200,000 Per Piece

Water Tube FBC Steam Boiler

Get Price Quote

4 Pass design, ensures better heat utilisation & ultimate thermal efficiency. Fluidised Bed Combustion furnace ensures very high combustion efficiency, up to 95% even with fuel, having very high ash & fine contents and having very low calorific value. Straight tube in generating bank enables manual cleaning & easy inspection. The rectangular headers are of welded type box headers with individual opening against each tube at both ends of generating bank. Hence, for cleaning & maintenance of any single tube only single door cap, weighing just 1.5 kg has to be opened. Larger tube diameter in generating bank, i.e. 76.2 mm OD, enables easy manual cleaning. Intermediate tube supports in the generating bank, which prevents tube sagging contributes to higher boiler life. Wide gap in tube spacing i e. 160 mm pitch, prevents inter tube space plugging by soot deposition, which permits trouble free operation without external cleaning as clogging of tube space with soot does not take place. Free floating front header takes care of longitudinal thermal expansion. Hence, thermal stresses are not developed during heating. This design enhances boiler life too. Man hole opening at both sides of the drum for easier access to drum internals. Larger diameter drum coupled with drum internal steam separators ensures dry steam even at full main steam valve opening. Moderately larger furnace area and higher free board height, above grate, makes the boiler capable to burn low grade, high volatill3 & ash contained solid fuel efficiently without reducing rated steam generating capacity. No inventory of spares, since nothing special is employed which is necessary to be procured urgently from us or which is not available in the free market.

Water Tube Coil Type Boiler

Get Price Quote

This is the conventional forced-circulation type water tube coil type boiler incorporating the unique principle of combustion known as ‘Reverse Flow. This increases the combustion efficiency and allows a high rate of heat release. It can be offered in both IBR and Non-IBR designs. Construction The boiler comprises of a jacketed MS shell housing a helical coil. The combustion air is forced through the jacketed shell by means of a centrifugal blower thereby getting pre-heated. The flame travels downwards inside the coil and the flue gases reverse upwards thereby giving two passes in the radiant zone ensuring complete combustion and higher heat flux. The third pass of the flue gases is in the convective zone between the coil and the inner shell. Flue gases then travel to the Economiser forming the fourth pass. Advantages Fully Automatic unit Unique four pass design High efficiency and low running cost Minimum site-work, low installation costs Instant steaming within 5 minutes of cold start Built-in economiser increases the operating efficiency Fail-safe design and dependable operating instruments Capacity Range Water Tube Coil Type Boiler is available in capacities from 100 Kg/hr to 1200 Kg/hr

Boiler Smoke Water Tube Solid Fuel

Get Price Quote

Smoke and water tube combination , external furnace solid fuel fired boiler with flexibility in fuel use. Capacities 2 TPH to 10 TPH.

Water cum Fire Tube IBR Steam Boiler

Get Price Quote

This design can burn a variety of fuels like Coal, Lignite, Rice Husk, Wood, Bagasse, Groundnut shells, and several other fuels thus providing you with lowest energy costs depending upon the fuel availability in your area Product Features : » This is a unique design membrane water wall type boiler combining the advantages of water tube & smoke tube designs. » The radiation zone of the furnace is covered on three sides by water tubes forming the first pass and the conventional smoke tube shell has tubes lined up forming the second and third pass of flue gases. » Thus the water wall furnace recovers the radiation heat of the furnace and the smoke tube shell provides large water & steam holding capacities to give maximum advantage. Advantages 1. Flexibility of fuels with choice of agro-waste fuels.2. Combines the advantage of water tube and smoke tube designs.3. High thermal efficiency and low operating costs.4. Dependable quality of components like valves, pumps, safeties & instruments.5. Can be converted to liquid / gaseous fuels as well.6. Heat recovery unit may be offered for increased efficiency.7. Easy access for cleaning and inspection.

Water Cum Smoke Tube Hybrid Steam Boiler

Get Price Quote

We, Triveni Boiler Pvt. Ltd. have established a reputation of renowned Manufacturer, Supplier and Exporter of Water Cum Smoke Tube Hybrid Steam Boiler, Water Cum Smoke Tube Boiler, Draft System and Boiler Mounting & Valve. In addition to this, we are also a service provider engaged in offering Consultancy Services and Technical Services of Boiler. Range: 1 TPH to 15 TPH Pressure: 10.54 Kg to 17.5 kg/ cm2 g Type: Water Cum Smock Tube Boiler Membrane Water Wall Panel Lined Radiant Furnace with Shell & Tube Boiler Pressure: Pneumatic Auto Firing Dumping Grate for Bagasse Firing Travelling Grate for Higher Capacities Steam Super Heating Provision for FBC Conversion Salient Features: Ideal for Fuels with higher Volatile Content & Lighter Fuel e.g. Lights, Rice Husk, Bagasse Ground Nut Shell etc. Very High THERMAL EFFICIENCY due to efficient Combustion & Minimum Radiation Losses Higher Free Board Space & Large Combustion Volume Minimum Choking hence Lower Cleaning Frequency Large Water Holdig & Steam Space Better Response to Fluctuating Steam Load Quicker Initial Steaming Superior MEMBRANE TECHNOLOGY In Packaged & Large Boilers Minimum usage of Refractory in Furnace hence Lower Maintenance Minimum Air Leakage Easy in Operation, Maintenance & Cleaning