WAVE SPRING UNBALANCED SEAL

6,800 Per Piece

10 Piece (MOQ)

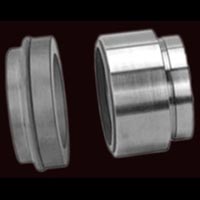

Wave Spring Mechanical Seal

700 Per Bag

1 Piece (MOQ)

Features For plain shafts Single seal Unbalanced Super-Sinus-spring or multiple springs rotating Independent of direction of rotation Variant with PTFE secondary seals for high chemical resistance Advantages Universal application opportunities Efficient stock keeping due to easily interchangeable faces Extended selection of materials Insensitive to low solids contents Flexibility in torque transmissions Self cleaning effect Short installation length possible (G16) Pumping screw for media with higher viscosity (M7..F) Operating Range Shaft diameter: d1 = 14 … 100 mm (0.55 ” … 3.94 “) Pressure: p1 = 25 bar (363 PSI) Temperature: t = -50 °C … +220 °C (-58 °F … +428 °F) Sliding velocity: vg = 20 m/s (66 ft/s) Axial movement: d1 = up to 25 mm: ±1.0 mm d1 = 28 up to 63 mm: ±1.5 mm d1 = from 65 mm: ±2.0 mm Materials Seal face: Special cast CrMo steel , Silicon carbide , Aluminium oxide (V) Seat G9: Carbon graphite antimony impregnated , Carbon graphite resin impregnated Silicon carbide Secondary seals: EPDM , NBR FKM , FFKM Springs: CrNiMo steel Metal parts: CrNiMo steel , Duplex (* Cannot be combined with seal face made of S Standards and approvals EN 12756 Recommended applications Process industry Chemical industry Pulp and paper industry Water and waste water technology Shipbuilding Lube oils Low solids content media Water / sewage water pumps Chemical standard pumps Vertical screw pumps Gear wheel feed pumps Multistage pumps (drive side) Circulation of printing colors with viscosity 500 … 15,000 mm2/s

Best Deals from Wave Spring Seals

Wave Spring Seals

Get Price Quote

we are prime manufacturer, exporter and supplier of wave spring seals in maharashtra, india. Wave spring seal (lie/711) is made as per industry standards and suitable for the most general applications. Offered at the competitive market prices, they are widely admired owing to their compact designs and high strength. more about wave spring seals : these seal can be also used in dirty application, as springs clogging do not take a place. These are no sticking or clogging making the design rubbed and reliable. Major advantage of this seal is that it is compact, axial length but no sticking or clogging. It reduced length of seal and no any spring clogging which help for long lasting of seal.

Wave Spring Mechanical Seal

Get Price Quote

10 piece (MOQ)

WAVE SPRING UNBALANCED SEAL

1,500 - 3,000 Per Unit

5 Unit (MOQ)

Description: Cost-effective single component seal Bi-Directional Easy to repair and clean Face materials can be easily changed Single unwelded wave spring or multiple springs Built to DIN 24960 Retainer with pumping screw available

Wave Spring Seal

5,100 - 31,922 Per piece

5 Piece (MOQ)

Wave Spring Mechanical Seal

2,200 Per Piece

10 Piece (MOQ)

Wave Spring our DW51 & DW56 group is widley used in centrifugal pumps and High Viscosity Handling pumps in purification plants, pulp & paper, chemical, petrochemical and sugar industries, brewery and pharmaceutical applications, abrasive media ,water, oils, fuels, low aggressive chemical substances and liquids containing solid particles, etc. . .

Wave Spring Seals

1,250 Per Piece

100 Piece (MOQ)

Wave Spring Mechanical Seal

1,200 - 9,000 Per Piece

1 Piece (MOQ)

Wave Spring Seals

3,000 - 6,000 Per piece

5 Piece (MOQ)

WAVE SPRING SEALS Wave Spring Seals are designed for bi-directional use and work with highly viscous, abrasive media, water, oils, fuels, light aggressive chemical substances and liquids containing solid particles. Most of the components are interchangeable, hence it proves economical and easy to maintain. All components are held together by snap ring which helps in easier installation and removal. Industrial Application: Sugar, Waste Water, Oil Refinery, Paper & Pulp Industries etc. Face Materials: Tungsten Carbide, Carbon, Silicon Carbide, Ceramic, Special Cast. Metal Component: S.S 304, S.S 316. Secondary Seal: Viton, PTFE, EPDM, NBR, FKM. Operating Limits: Pressure : 16 bar Temperature : -50˚C to 250˚C Speed : 20 m/s

Wave Spring Mechanical Seal

1,500 - 3,000 Per Piece

1 Piece (MOQ)

Wave Spring Mechanical Seal

1,400 - 15,000 Per Piece

Wave Spring Mechanical Seal

1,000 Per Piece

Wave Spring Seals

Get Price Quote

Wave Spring Seals

2,500 - 4,000 Per piece

1 Piece (MOQ)

Wave Spring Seals

Get Price Quote

We are instrumental in offering superior quality Wave Spring Seals in the BCS-WS Series. Our Wave Spring Seals are designed to work in fluids with suspended particles, sledges, high viscosity liquids, etc. The uniform force that a Wave Spring Seal provides gives consistent axial movement and dynamics. The design features of crest-to-crest wave spring which reduces the risk of corrosion and fracture can be experienced with this Wave Spring Seal. Compact in design, these Wave Spring Seals can be utilized in smaller stuffing boxes.

Wave Spring Seals

Get Price Quote

Wave Spring Seals

Get Price Quote

Wave spring seals, Spring Steel & Stainless Steel in 2 3 4 waves, gap type, overlap type, double wave type A wave spring is made from coiled flat wire with waves added to give it a spring effect. The on-edge-coiling process creates a circle with one or more turns to specifications in any diameter and any number of specific designed waves. When compared with typical coil springs, wave springs have equal performance with about half of the overall free height. This not only provides for space savings, but also smaller assemblies that use less materials, hence lower production costs. Wave springs are a precision spring and available in many styles and materials.

Wave Spring Mechanical Seals

Get Price Quote

Designed to match the clients requirements, our Wave Spring Mechanical Seals meet the highest quality standards across the entire industry. These Wave Spring Mechanical Seals are manufactured using superior raw material and are quality tested using CAD, Solid Edge, 3D Mex facilities. Widely used for various purposes, we make our Wave Spring Mechanical Seals available at very moderate price. Applications Highly corrosive chemicals High temperature applications Petroleum refinery

WS7 Wave Spring Seals

Get Price Quote

1 Container (MOQ)

MTS WS7 is a positively, driven wave spring seal, utilising crest to crest wave spring technology, offering excellent axial movement capabilities. Designed to suit DINCharacteristics Unbalanced Mechanical Seal. Independent of direction of rotation. Operating Limits p: <20 Bar ; V: <15 m/s T: -20 / +180ºC Temperature is based by material selection. Operating limits are based on PV factor.