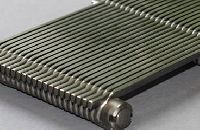

Wedge Wire Sieve Bend Screen

99 - 100 Per Pieces

We are offering wedge wire sieve bend screens. Champion wedge wire sieve bend screens can be custom made and designed for application in a wide range of industries. Used to separate solids from liquids, the curved screen of a sieve bend provides greater capacity than flat wedge screens due to increased gravitational forces on material flowing against the curve. Sieve bend screens are also known as side hill screens, parabolic screens, run down screens, gravity screens and dsm screens. at champion our high quality sieve bend screens consist of a concave curved profile wire screen mounted in a frame with the screen openings either perpendicular or parallel to the flow.

Wedge Wire Screen

6,000 - 95,000 Per Pc

1 Piece (MOQ)

When you require the most effective method to remove solids, trust our ClearBlu wedge wire waterfall systems. View five reasons our products are the best.GWWSL manufacturers wedge wire waterfall screens as a highly efficient and cost-effective alternative to other solids removal systems. A number of factors make these wedge wire screens an excellent choice.Wedge wire screen The wedge wire screens have a very steep angle. This allows water flow to push screened material off into a dewatering hopper. .5 mm screens will actually separate material as small as .25 mm. Automatic spray bars keep dried material from clogging the wedge wire screens. Because they are timer activated, they use 90% less water than rotary screens. Stainless steel construction means acidic wastewater is no challenge. Screening solids before pH balancing can reduce chemical consumption by 60%. Solids can soak up significant amounts of the chemical. Models0-150 GPM Wedge Wire ScreenThis wedge wire screen is designed for flows from 0 to 100 GPM for hydro screens. GWWSL screens are unique in that they have a 60-degree slope and are self-cleaning in most applications. They have no moving parts. The concept is simple: run the wastewater over a weir and down over a wedge wire screen. The solids are pushed off the screen and the liquids pass through the wedge wire.Wedge wire screenThere are several important factors in selecting a good waterfall filter. First, the spacing between the wedge wire bars can vary. Second, the top of the wedge wire is flat (wedge wire is made of flattened tubing) and the tops should be canted slightly so that they trap the water. Third, there needs to be sufficient runway at the top so that the water can gain velocity. This is accomplished by placing a smooth section of stainless just below the weir at the top. Fourth, the slope of the wedge wire needs to be steep. This is counterintuitive. It would seem that you would want a low slope to slow the water. Instead, you want a steep slope so that you don't build up solids on the wedge wire screen. Water is heavy and will pass through a steep screen. Manufacturer: MiTMWaterfall screen150 to 250 GPM Wedge Wire ScreenThe Model 2 waterfall screen has six square feet of wedge wire screen surface and is half the size of the Model 3. This wedge wire screen effectively removes solid particles from a waste stream. Like the other types, this model uses very little energy and requires only a minimum amount of maintenance. It's ideal for many different applications including agriculture and manufacturing.400 GPM Wedge Wire ScreenThis unit will handle flows up to 400 gallons per minute. It has a 1 MM wedge wire screen. The key to hydro screens is having the correct angle on the screen and having enough runway for the water so that it gains sufficient velocity over the wedge wire screen. This seems counterintuitive. Most manufacturers lower the slope and try to slow the water. This creates clogging and water bypass.Our unit has a 60-degree slope. The screen is 48" wide and 36" long. The unit is stainless steel.Wedgewire Waterfall ScreensWaterfall screens are ideal for effectively removing fibrous and solid particles from a waste stream. An automatic self-cleaning spray bar runs on a timer to continually keep the screen free from debris buildup. These screens use very little energy and require very little maintenance.Applications: Wineries Breweries Food Processors Agricultural Industrial (garbage companies,municipal yards, etc) Wedgewire waterfall screens are available in three sizes: Number One, 0-65 GPM Number Two, 65-150 GPM Number Three, 150-300 GPM. Standard wedge wire is available in 0.5 mm and 1 mm spacing, but custom spacing is available. All models are available with stands in carbon or stainless steel. For solids handling, self-dumping dewatering hoppers from ¼ yard to 5 yards in size are available. Dewatering screens are stainless steel mesh behind stainless steel perf plate with ½" openings. The hopper is carbon steel with an option to come painted or galvanized.

Best Deals from Wedge Wire Screen

Wedge Wire Screen

Get Price Quote

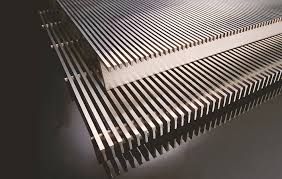

We are engaged in manufacturing, exporting, importing, and supplying Wedge Wire Screen of optimum quality. The Wedge Wire Screens offered by us are manufactured using Triangular wires rigidly welded to rods or flat bars to form a precise opening. These fabricated Wedge Wire Screen offers narrow opening with high strength which normal wire mesh screens cannot offer. Clients can avail the Wedge Wire Screen from us at market leading price. Construction : Wedge wire screen construction. The total thickness of the construction is calculated as follows: T = Profile Wire Height +Support Height -(IMM) welding penetration Wedge Wire Screens Applications : Liquid / Solids Separation Resin Traps & Pressure Screens Strainers for Pumps or Compressor Protection Support Grid For Uniform Fluid Collection In Filter Hub & Header Lateral Screens Systems Solid Removal From Process Wastewater Salt Water Intake Screens & Fiber Removal Screens Cylinder for Rotary Screens Recovering Solids & Pulps Thickening Applications Heavy Media Recovery & Product Dewatering Screens Sieve Bend Screens & In-line Strainers Nozzles for Tube Sheets Up flow Clarifiers Gravity Filters Under Drain Systems Specifications : Number Width mm Height mm Angle L - 30 0.75 1.3 13o L - 43 1.10 2.20 13o L - 63 1.52 2.54 13o L - 80 2.00 4.15 08o L - 90 2.26 3.53 13o L - 109 2.82 4.45 13o L - 128 3.00 5.60 13o L - 133 3.35 6.20 13o L - 138 3.50 6.60 13o L - 155 3.90 6.81 13o

Wedge Wire Screen

Get Price Quote

We Manufacture and Supply high quality Wedge Wire Screens that are made from looped wires formed into a deep wedge-shaped section. According to buyer’s needs, we can make available Wedge Wire Screen in various shapes and forms including flat panels, curved sieve bends, conical baskets and cylinders. Our testing team ensures that Wedge Wire Screen passes all quality checks before supplying. Our clients trust us for delivering only premium Wedge Wire Screen at reasonable price. We always deliver all orders on time. Advantages : Wedge Wire Screens provide a unique combination of the most important features required for maximum screening efficiency - Free Clearance : The wedge-shaped sections of the wire from aperatures that become progressively wider in a downward direction, thus ensuring rapid flow of material through them. Clogged and blinded aperatures are reduced to an absolute minium. Lateral Strength : In our opinion no form of screening surface witl i apertures as fine as those of wedge wire screens, can compare with the mechanical strength and working efficiency of wedge wire. Percentage Open Area : For a given aperature size, wedge wire screens have a much larger percentage of open area than conventinal sieves. Wearing Life : Owing to a greater wearing area being provided by hat top surfaces, wedge wire screens retain their aperature for a longer duration than round wire screens. Some other advantages of Looped type of wedge wire screens over other type of screens and also other type of wedge wires are : Self Supporting High Abrasition resistance Low pressure drop High resistance to Vibration Looped Wedge Wire Screen construction is particularly recommended when high Vibration resistance and fine accurate aperture are needed. Types Of Screens : Flat Panels Curved Screens / Sieve Bends & Cylinders Centrifuge Baskets Rotary Wedge Wire Screens Run Down Screens Industrial Applications : Wedge wires can be employed in almost all industrial processes which require very fine and uniformly accurate aperture, combining rapid discharge of material and high mechanical strength. Some of the specialized applications of these screens are given below -Wedge wire screen used in industries for water, oil filtration equipments like Filteration Equipments Filtration Systems. Filters. Wedge Wire Screen. Also Used In : Coal and Coke Washeries : Flat and curved wedge wire screens and Centrifuge Baskets with suitable re-inforcements are used for dewatering processes on stationary and moving frames, suction filters and centrifugal driers. Ore Beneficiant Plants : In Iron and other Ore benificiant plants, wedge wire flat screens, Curved screens and Centrifuge baskets of fine and very fine aperture are used for efficient Dewatering and recovery of fines. Sugar Mills : Flat, curved and cylindrical wedge wire screens are used for Juice Filtration and Bagasse Separation drainage in tanks in conjunction with scraper conveyors as well as for draining crushed sugar cane supply in D.S.M. Screens. Cement, Chemical and Fertilizer Plants : Flat panels, Curved wedge wire screens, Cylinders and Centrifuge baskets with cylindrical type, conical type and pusher type have many and varied applications in these industries. Cellulose, Wood and Straw Pulp and Board Industries : Wedge Wire cylinders, Flat panels and Centrifuge baskets are used for preliminary screening for knot catchers and for efficient fibre recovery Wedge wire screens ensure greater efficiency than the conventional perforated or machined slotted plates. Sewage, Effluent and Water Treatment : Flat wedge wire decking in final settlement tanks provides tertiary treatment for the reduction of suspended solids. It is also the medium used in a technique for the consolidation of sludges where the rate of filtration is controlled at low operating pressures. Sewage, aluminium hydroxide, iron hydroxide and other industrial sludges are being successfully dewatered on wedge wire. Cross Rods Diameter And Pitch : The Standard sizes of Cross rods and pitch provided are - 7.6mm diameter cross rod at 70mm pitch. 12mm diameter cross rod at 70mm pitch. 7.6mm diameter cross rod at 66mm pitch. 12mm diameter cross rods at 66mm pitch. 5mm diameter cross rod at 70mm pitch with two spacing lugs on the profile wire. 5 mm diameter cross rod at 66mm pitch with two spacing lugs on the profile wire.

Wedge Wire

150 - 500 Per Kilogram

600 Kilogram (MOQ)

Specification Shape : Wedge Shape Dimension : as per customer requirements Feature : Good Quality/ Ready to Use / Weldable Finishing : As Drawn Grade : SS316L, SS410, SS304 Description Widely used in paper and pulp manufacturing industry welded in wedge screen to dewater the slurries. This is manufactured in SS316L Prime Material with perfect edges, angles and dimensions to ensure it meets it's end use precisely. Contact us to know more about this product and how such Bulb Type designs can be manufactured and developed for your end use.

Wedge Wire Screen

Get Price Quote

Designed with perfection, Wedge Wire Screen is developed as per the exact specification of the clients. Manufactured using V Wire, Wedge Wire Screens that we provide are highly demanded in the markets. Wedge Wire Screens are extensively used in sugar mills for effective separation of bag gase form juice. Wedge Wire Screens are obtainable at highly competitive rates. Features Precise dimensions Light in weight Resistance to abrasion Longer working life High tensile strength Durable Minimal maintenance Applications Fertilizer Plants Foundries Paper & Pulp Industries Sugar industry Stone Quarries

Wedge Wire Screen

Get Price Quote

Wedge Wire Screen is used in various industries for solid-liquid separation, mining processing cement etc. Our Wedge Wire Screen is the unique combination of the most crucial features required for maximum screening efficiency. With high friction and thermal strength, our Wedge Wire Screens have gained many accolades from the customers. Our Wedge Wire Screen has the surface made of either looped wires assemble on cross rods or all welded constructions. We are offering Wedge Wire Screen in slit opening starting from 0.25mm. Avail from us Wedge Wire Screen in the required size, shape and form with assured durability. We are counted among the leading Wedge Wire Screen Manufacturers, Exporters and Suppliers from India.

Wedge Wire Screen Cylinders

1,500 Per Meter

Wedge wire screen cylinders are initially manufactured as cylinders with the slots and wires running radial around the outside and support rods internal and axial.In each application every intersection of wedge wire and support rod is welded for strength.Various wire and support rod sizes can be used to produce screen designs for your particular application.

Wedge Wire Screen

Get Price Quote

Wedge wire screen is a type of filtering screen, which is composed of profile wires and support rods. The profile wires are commonly triangle wire and the support wire of wedge wire screen can be triangle wire, round bar, flat wire or wedge wire. Wedge wire screen has various types and specs. The classification of wedge wire screen are mainly according to the shape of screen.

Wedge Wire Screen

Get Price Quote

Wedge wire screen to attain their desired & specific opening. Patter of Weave depends mainly on the Application. Wire of any diameter & composition can be used.

Wedge Wire Screen

100,000 - 1,000,000 Per pcs

5 Piece (MOQ)

Wedge Wire Screen Panel

Get Price Quote

10 Piece(s) (MOQ)

We are offering Wedge wire flat screen panels,Sieve Bend,Centrifuge baskets ( Any Make),Poly wedge flat screen panels.

Wedge Wire Screen

220 Per Square Feet

Ss Wedge Wire Screen

Get Price Quote

We are pleased to introduce jagtap engineering works as one of the leading manufacturers and suppliers of welded wedge wire filtration products. We also take pride to be india�s first to introduce the in-house developed proprietary metal-to-metal fusion technology for manufacturing jagtap's welded wedge wire screen products. jagtap welded wedge wire screen is a different type of manufacturing technique, rather than resistance welding or looped system of wedge wire screens. jagtap�s wedge wire screens are available in flat panels, conical baskets, centrifuge basket, cylinders, tubes, sieve bend and also complete structures for salt, coal & ore, sugar, food, mineral, waste processing, petrochemical and chemical industry. Welded wedge wire elements of our range includes basket, screen drums, sieve bends, candles, resign traps, support grids, laterals, under drain pipes and other custom-made wedge wire components. please feel free to get in touch with the undersigned for any clarification or information ph: + 91-265-2645415 and mobile: +91 9898023982 or mail us at viejayjagtap@gmail.com for more details pelase visit our website : www.jagtapengineering.com thanking you, & we look forward for a long mutually beneficial association. yours faithfully for jagtap engineering works mr. Viejay jagtap jagtap engineering works your reliable filtration partner an iso 9000:2008 company 679-680 gidc makarpura industrial estate, vadodara � 390010 (gujarat), india t : +91 265 2645415 m : +91 9898023982 e-mail : viejay@jagtapengineering.com / viejayjagtap@gmail.com / info@jagtapengineering.com website : www.jagtapengineering.com

Wedge Wire Screen, Rotary Screen

Get Price Quote

We are offering wedge wire screen rotary screen dsm sieve bend screen. we jagtap engineering works are the manufacturer of wedge wire screen, rotary screen, rotary screen drum, rotary juice screen, sieve bend screen, dsm screen, wedge wire flat panel screen, rotary screen drum

Wedge Wire Screen

Get Price Quote

Consists of conical section wires resistance welded on to special cross bars. This provides a straight and continous, uninterrupted slots for free and easy flow. The feed is evenly distributed over the entire screen area, resulting in higher open area and increased life.

Wedge Wire Screen

Get Price Quote

It is a sieve made from looped wires formed into a deep Wedge-Shaped section. It is used for stringent filtration requirement. Individual wedge wires are built into ‘panels’ by threading cross rods of suitable diameter through loops. The whole is then clamped & made secure usually by riveting or putting rings nuts over the cross rod ends or by welding. The Wedge Wire Screens can be supplied in various shapes & forms as per requirement. Special screens can be developed for customized applications. These Screens are used in Foundries, Sugar Mills, Fertiliser Plants, Stone Quarrys, Paper & Pulp Industries etc.

Rotary Wedge Wire Screen

Get Price Quote

Ganesh wedge wire has developed rotary screens complete with side flanges and support/drive drums of stainless still mainly for sugar and other chemical plants to achieve very efficient filtration. Our rotary screens have very strength coupled with very high open area and rigid construction. Rotary screen sizes from 1000mm to 5600mm long. Flow rates are depend on rotary screens area and size.

Wedge Wire Screen

Get Price Quote

We make Wedge Wire Screen of finest quality. These Wedge Wire Screens are suitable for variety of applications such as sugar coal, mining processing cement etc. The screen surface is either made of looped wires assemble on cross rods or has all welded constructions. A high open area, non clogging filter surface & high precision slots are typical of wedge wire filtration products. These Wedge Wire Screens are available in slit opening starting from 0.25mm & can be delivered as per customers requirement.

wedge wire juice screens

Get Price Quote

wedge wire juice screens, cane mud filters, Industrial Process Equipment