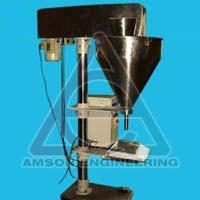

Weighmetric Powder Filling Machine

Get Price Quote

Thanks to our excellence at meeting customer needs, we have positioned ourselves as a prime Manufacturer, Exporter & Supplier in the industry. We offer Weighmetric Powder Filling Machine in a wide range of designs and specifications to choose from. Our outstanding quality team runs various quality tests to make sure we exceed the quality standards. These quality checks make certain its durability, fine finish and impeccable quality. Structure and Working : Powder filler is made strong and vibration free by its specially designed Pillar structure. This is made from Mild steel ROUND Pipe section of good thickness Hard chrome Plated, which holds drive unit, hopper and related parts. A drive motor and an electromagnetic clutch brake assembly are driving the Augur. A safety cover is provided to this assembly to protect from accidents and to avoid dust from drive. Main driven shaft connected to the drive shaft through a Bearing housing holds and rotates freely when the machine is operated. A stirrer blade provided separately which is operated independently over the driven shaft. The driven shaft is holding an accurately machined stainless steel AUGUR which performs the filling inside the Nozzle. The lower parallel flights of the auger within the funnel are machined to a constant pitch so that, when filled, each pitch has a precise volume. The auger drive rotates the auger at constant speed to produce a continuous dosing flow. The agitation blade, generally separately driven and controlled, rotates in the opposite direction to the auger breaking any bridge that tends to form in non-free flowing powders. The agitation blade extends right down to the throat of the funnel preventing rat-holing and cavitation and ensuring that the flights are fully filled. The start/stop signals to the auger drive control the pre-set weight in Weigh metric fillers. Technical Specifications Afae1000 Machine size - 1000 L X 700W X 2100mm height. Drive Motor - 1 HP 230VAC 50Hz, 1440 rpm. with VFD(Variable Frequency Drive) Power - 220VAC 50Hz Single Phase Stirrer motor - 1 Hp 32RPM 230VAC Worm Geared Electromagnetic Clutch- Brake - HSCBC 100, 24 VAC Cryotron Make All material contact parts in S.S. 304 Stainless steel 304 Augur (Screw) type filling. Hopper size - 40 Litres (S.S 304), 18 Gauge, mirror finish for AFAE1000 Fill capacity - 50-1000 gms at a time as per set time, Weigh balance - Maximum load capacity - 3 Kgs. Maximum Fill capacity - 1000gms, as per set weight on weigh balance.(easily settable) Output - 15 fills per minute Additional features : Augur Based filling equipped with digital Weigh balance (load cell). One touch Start by a foot-switch Drive through electro-magnetic clutch brake system to get high accuracy filling. High output and increased efficiency. Slow speed geared motor attached to stirrer helps to feed augur uniformly Output of 15 fills/minute can be achieved. High Accuracy up-to +/- 0.5% of fill volume. Low maintenance needed in this model.

Digital Control Particle Weighing Filling Machine

16,000 Per Piece

1 Piece (MOQ)

Best Deals from Weighmetric Filling Machine

Bulk Powder Weighmetric Filling Machine

Get Price Quote

1 Piece (MOQ)

Weighmetric Filling Machine

Get Price Quote

We follow strict quality strategy, guidelines and thus, to sustain good quality standards, we carry out stern examination of the raw inputs used at the initial stages. Place orders with us, timely deliveries of the same are our prime responsibility! Features Precision engineered Smooth operation User-friendly

Weighmetric Filling Machine

Get Price Quote

Weighmetric Filling Machine

15,000 - 45,000 Per Piece

Weighmetric Filling Machine

305,000 Per Piece

Weighmetric Filling Machine

Get Price Quote

1 Piece (MOQ)

Weighmetric Filling Machine

Get Price Quote

Machine is vertical filling machine for tea, sugar, pulses, grains, wafers, namkeen, dray fruits in pouches, jars, bottles or containers. Manually the container or pouch will be kept for filling the product. Filler weighs the filling material in individual pan mounted on the load cell to get maximum output and accuracy. The load cell output is processed directly by the PLC and its modules. The vibrators and Pan opening is controlled by PLC itself. Two separate vibrator controllers are provided to adjust the feed rate of the vibrator feeders. As soon as the set weight is achieved the vibrators are switched off and the ready pay is discharged into the pouch as and when required. After filling the desired quantity the pouch will be taken for sealing or if it is a container will be taken for capping

Linear Weighmetric Filling Machine

250,000 - 280,000 Per Piece

1 Piece (MOQ)

Linear Weighmetric Filling Machine is used for filling bottles and containers in different capacities. It is made by using latest technologies under the stern guidance of our diligent professionals keeping in mind the set industrial norms. Further, our offered filling machine is checked by our quality controller on different quality parameters before delivering to our valued customer ends. This Linear Weighmetric Filling Machine is available in different specification and praised for their unique features like energy efficiency, less maintenance, easy to operate and flawless performance.

Weighmetric Filling Machine

Get Price Quote

Weighmetric Filling Machine

55,000 Per Piece

Weighmetric Filling Machine

Get Price Quote

VFFS MACHINES Weighmetric filling machine is Weigh-Metric basis filler, Weighmetric filling machine is suitable to fill 50gm 1Kg & (5Kg Multiple Strokes of 1Kg) of PulsesGranules in Readymade Laminates Pouches Wighmetric filling machine is widely used for free flowing granules, vffs machine suitable Chips, Puffed Snacks, Namkeen, Dry Fruits, Wrapped Candies, Macaroni, Biscuits, Pasta, Seeds, Breakfast Cereals, Chips, Puffed Snacks,Dry Fruits, Wrapped Candies, Macaroni, Biscuits, Pasta, Breakfast Cereals, Potato Chips, Kurkure, Macroni, Indian Namkeen, Nuts, Soya Chunks, High Counts Biscuits etc Vffs Pouch packing machine with latest version filling technlogies

Weighmetric Filling Machine

Get Price Quote

1 Piece (MOQ)

Weighmetric Filling Machine

Get Price Quote

We make sure that our payment procedure is safe and simple. We offer our clients methods like online payment gateway, electronic funds transfer, cash, bank deposits and various others. Ranked amidst the established names, we deliver the truly appreciable products from Mumbai(India).

Weighmetric Filling Machine

400,000 Per Piece

1 Piece (MOQ)

Weighmetric Filling Machine

Get Price Quote

Machine is vertical filling machine for tea, sugar, pulses, grains, wafers, namkeen, dray fruits in pouches, jars, bottles or containers, Manually the container or pouch will be kept for filling the product, Filler weighs the filling material in individual pan mounted on the load cell to get maximum output and accuracy, As soon as the set weight is achieved the vibrators are switched off and the ready pay is discharged into the pouch as and when required, After filling the desired quantity the pouch will be taken for sealing or if it is a container will be taken for capping.

Weighmetric Filling Machine

Get Price Quote

We are the leading exporters and supplier of this products.

Weighmetric Filling Machine

Get Price Quote

Weighmetric Filling Machine

Get Price Quote

Weigh Metric filling machine can handle most any type of product that will move over a vibratory feed pan. The product moves over a vibratory feed pan (or several feed pans) into a weigh hopper. The hopper is mounted on one or two strain-gauge load cells that communicate with the microprocessor. When the programmed weight is reached, the vibratory feed stops and the hopper dumps into a bag, box or other selected container. Changeover to different size and types of packages is quick and easy. And each product setup can be stored in the microprocessor for easy recall.