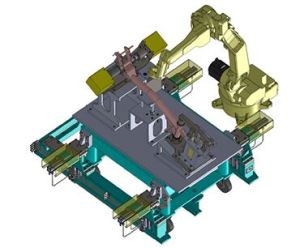

Robotic Welding Machine

800,000 Per Set

1 Set(s) (MOQ)

We are the leading supplier of this products.

Robotic Laser Welding Machine

Get Price Quote

1 piece (MOQ)

Description: SILROBOWELD it is modern 2 to 6 kw laser welding delivers high quality, high precision weld that is not possible with conventional CO2 welding. Fiber laser technology allows to processes different types of thickness and materials, including similar and different material. SILROBOWELD operates in standard laser safety booth to protect user from shorter wavelength emitted by fiber laser. SILROBOWELD its takes higher level of precision and productivity using fiber laser processes material such as brass, copper, and aluminum. Fiber laser technology is with unmatched beam quality and electrical saving, due to this requires less maintains to oscillators to generate beam. In SILROBOWELD teaching is done with inline CCD camera which is easy , fast and accurate teaching of welding path. Another key featuresis rotating mirror in welding head, which helps to rotate beam direct path of welding, it can make any shape of laser beam like 8, O, line (vertical or horizontal)

Best Deals from Welding Robot

Robotic Laser Welding Machine

2,500,000 Per Piece

1 Piece (MOQ)

Spot Welding Robot

Get Price Quote

RoboWeld - Robotic Laser Welding

1,200,000 Per piece

Yaskawa Welding Robot

1,000,000 Per unit

MULTISAMPLE ROBOTIC

Get Price Quote

The innovative Omni Prep Multi-Sample Laboratory Homogenizer is specifically designed to streamline the labor and time intensive homogenization process and to make it more comfortable for the user. The Omni Prep features our new Whisper Drive Technology – a brushless motor that is virtually maintenance free, is ultra quiet during operation, and uses about 10% of the power required to process 6 samples individually. Unlike brush motors, since the motor holds its processing speed to +- 1% accuracy throughout the homogenization cycle, Whisper Drive Technology guarantees accuracy and repeatability regardless of fluctuations in sample size or sample viscosity.

Robotic Welding Machine

60,000 - 100,000 Per Piece

Welding Robots

Get Price Quote

Welding Robot

100,000 Per Piece

Fanuc Welding Robot with Controller and Panel, Bj2002

100,000 Per Piece

ATOM 50 Welding Robot

3,000 - 7,000 Per piece

1 Piece (MOQ)

ROBOTmake : RRROBOTICA model : ATOM 50 Max. workpiece weight : 50 Kg

Spot Welding Robot

2,000,000 - 2,500,000 Per Bag

1 piece (MOQ)

Kawasaki Robotics – Spot Welding Solutions Kawasaki Robotics offers cutting-edge Spot Welding robots designed to deliver high-quality, precise, and efficient welding solutions for automotive, industrial, and manufacturing applications. Spot welding is a crucial process in industries that require the joining of sheet metal parts, and Kawasaki's robots are built to meet the demands of high-volume production lines. Key Features: Precision and Consistency: Kawasaki's spot welding robots are equipped with advanced controls to ensure precise, consistent welds, reducing defects and ensuring high-quality results. Speed and Efficiency: These robots are capable of performing spot welds quickly, contributing to reduced cycle times and increased overall production efficiency. Versatile Payloads: The robots are designed to handle a wide range of welding applications, from lightweight to heavy-duty tasks, making them suitable for various industries. Compact and Flexible Design: Kawasaki's spot welding robots are engineered with a compact design, allowing for easy integration into existing production lines and maximizing workspace efficiency. Advanced Technology: With cutting-edge control systems and sensor technology, Kawasaki robots can adapt to different welding conditions and materials, ensuring optimal performance across diverse applications. Whether you're manufacturing automotive components or working in any other industry requiring reliable and high-performance welding solutions, Kawasaki Robotics' spot welding robots provide the perfect combination of speed, precision, and flexibility. Enhance your production line with Kawasaki's state-of-the-art robotics technology.

Welding Robot

1,500,000 Per Piece

Panasonic Welding Machines and Robots

Get Price Quote

We are authorized distributor of Panasonic welding machines and Robots We have complete range of Panasonic welding machines and Robots Mig welding Tig welding Arc welding If any query regarding welding machine please call on 9041433848 7707810999 Best Regards Avinash Sharma Fairdeal Components Limited Panasonic India North India

Robotic Welding Machine

Get Price Quote

1 Piece (MOQ)

Robotic Walding Excellence : Our robolic welding machines are craftad with precision, harnessing the power of advanced robotics to deliver unmatched accuracy and repeatability. Whether it's automotive, aerospace, or heavy machinery, our robolic welding solutions ensure seamlass integration into diverse manufacturing processes. Customized Selutions : Recognizing the unique requiremsnts of sach industry, we pravide tailor-made welding solutions. Our team of engineers collaborates clossly with clients to understand their spacific needs, snsuring that cur machines not only meset but exceed expectations. Quality Assurance: Quality is at the heart of everything we do. Our manufacturing processes adhaere to the highest industry standards, and each welding machine undergoes rigorous testing to guarantee optimal performance, durability, and safety. Innovation and Sustainability: As a forward-thinking company, we are committed to sustainable practices and continucus innovation. Our R&D department is a hub of creativity, constantly exploring new technologies and methodologies to push the boundaries of what is possible in the world of welding. Conclusion: GO ROBO MECHATRONICS is not just a manufacturer; we are architeclts of progress, shaping the future of welding technology. With a relentless commitment to quality, innovation, and customer satisfaction, we invite you to join us on a joumsy where precision mests fusion, and excellence is not just a goal but a standard.

Spot Welding Robot

Get Price Quote

Spot welding robot Flexi Shunt for Spot Welding Robots CB1-300, CB1-350, CB1-525, 303S1005, 303S1004 ETC. as per Denyo and Obara, Robotics Gun Arms and Shanks D-09-1810, D-09-1805 etc.

Robotic Welding Machine

1,300,000 Per Unit

Robotic Welding Shank

Get Price Quote

1 Piece(s) (MOQ)

PARENTNashik offers excellent quality spot welding shanks, holders & gun arms for manual & robotic spot welding gun & systems. These shanks are available in cucrzr & becu copper alloy.

Motoman ARC Welding Robot

Get Price Quote

Motoman is the world leader in arc welding robotics with industry firsts such as patented multiple robot control and “Master Arc” MA-series robots. Integrated through-the-arm cabling improves weld accuracy, improves torch access, and reduces downtime. Motoman backs the performance of the MA-series robots with the industry’s first two-year torch cable warranty. This patented torch cable design was key to the success of the EA series robots and is not available from other companies. Motoman also was the first with an extended reach (>3.0 m) robot for arc welding (HP50-20) and has an extended reach MA-series robot (MA1900). Motoman is extending the success of these arc welding arms with the introduction of the first 7-axis arc welding robot. The flexibility of the VA1400 model can be used to reduce floorspace and achieve higher robot density for increased production. The unique “elbow” axis of the arm also allows the robot to reach around tall parts or reach into boxy parts.

ROBOTIC ROLLER WELDING Machine

Get Price Quote

FEATURES Used for full automatic welding for inner and outer circumferential weld of roller bearing block. Double-robot + Torch clean and wire-cutter device, realizing unmanned full automatic welding. Provided with special water-cooling torches, which work reliably. The system can make automatic adjustment to adapt to different pipe length and diameter without human intervention. Can be integrated into Roller Automatic Production Line, so as to reduce secondary invested cost for customers

Welding & Painting Robot

Get Price Quote

Robotic Tig Welding Machine

2,000,000 Per Piece

1 Piece (MOQ)

Welding Robots

Get Price Quote

PRODUCT DISCRIPTION & FEATURES To create a weaven pattern, you just teach the starting point, amplitudes, turning point and ending point. Time for teaching will be drastically reduced. Parallel Shift + RT Axis Rotating Function Time for teaching of some work pieces will be drastically reduced by those shift function. Overlap Function In case of interruption during CO2 / MAG welding, the torch is stepped back by reboot and resume the welding from the ending point of welding. Multi Welding Function One root controller can register maximum 5 digital welding machines. Manipulators Compact and wide working envelope Superior to environment resistance High speed and smooth movement by robust arm and latest software servo control Easy to expand to various systems Improved dust and drip proofing TECHNICAL SPECIFICATIONS

Spot Welding Robot

858,000 Per Piece

Welding Robot

Get Price Quote

We are the manufacturers and supplier of this products.

Motoman Spot Welding Robots

Get Price Quote

Motoman innovations in the robotic spot welding market include ES-series “Expert Spot” robots with an integrated spot harness. With spot utilities (power, water, air, motor and signal lines) integrated into the profile of the robot arm,

Spot Welding Robots

Get Price Quote

200000 Piece (MOQ)

Welding Robot

Get Price Quote

Robotic arc welding with MOTOMAN robots will increase output, reduce manufacturing costs whilst providing consistent high quality. It offers an ideal solution for customers with With over 30 years experience and continuous development we are in an ideal position to help you achieve improved productivity and quality. Choosing a YASKAWA robot welding solution gives you confidence and access to a complete range of arc welding related products, systems and services. edium to high production who need to compete in a challenging business climate.

Spot Welding Robot

Get Price Quote

To meet the stringent quality requirements for welding while ensuring 100% availability and reliability of the individual components and welding robots, controlled optimised cooling of the welding is imperative. Operators must therefore be in a position to quickly and accurately detect any leaks in the cooling system caused by worn electrode caps and other defects.