Brass Stove Welding Rods

435 Per Kilogram

200 Kilogram (MOQ)

PP H Sheet Rod Welding Rod Parts Machining Components

Get Price Quote

10 Set (MOQ)

Polypropylene Homopolymer (PP-H) is the most widely utilized. PP-H offers a high strength to weight ratio and is stiffer and stronger than copolymer, this combined with good chemical resistance and weldability allows this material to be used in many corrosion resistant structures.POLYPROPELENE GRADE OF MATERIALPP-H (Polypropylene - Homopolymer)PP-H RangeSheets (standard and customer sizes), rods, welding rods, cut-to-size blocksPP-H Area Of Uses Chemical production & treatment installations Civil engineering area Food production equipment Farming and agriculture zone Pharmaceuticals and bio industry Water process construction

Best Deals from Welding Rods

aluminum welding rod Er4043

480 Per kg

5 Kilogram (MOQ)

Copper Brazing Welding Rods

Get Price Quote

The company is a reliable Supplier of Copper Brazing Welding Rods. The Welding Rods offered by us are manufactured using quality-tested copper material and sophisticated technology. We ensure that the Rods offered by us are manufactured in adherence with set industrial norms. We hold the expertise to deliver bulk orders of these within the stipulated time. Buyers can obtain these at market-leading rates from us. Features : Rust proof Fine finish Easy maintenance

Friction Welded Induction Hardened Drill Rods

28,500 - 36,500 Per no

10 Piece(s) (MOQ)

brass welding rods

350 - 450 Per Kilogram

35 Kilogram (MOQ)

Plastic Welding Rods

Get Price Quote

Welding Rods

Get Price Quote

10 Pack (MOQ)

Stainless Steel Mangalam Welding Rods

3,200 Per Pack

2 Pack (MOQ)

PP Welding Rod

160 Per Kilogram

100 Kilogram (MOQ)

Hdpe Welding Rod

24 - 25 Per Meter

1000 m (MOQ)

We specialize in manufacturer of high quality HDPE WELDING ROD extruded products since many years, with specialization in the manufacture of HDPE WELDING ROD Size 1mm,2mm,3mm,4mm,5mm

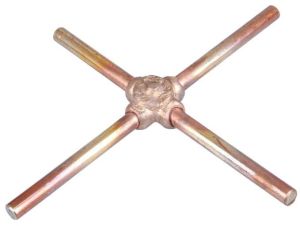

Welded Clamp Copper Bonded Earth Rod

500 - 2,000 Per Piece

200 Piece (MOQ)

Features: High quality Reasonable price Corrosion resistant

stainless steel welding rod

290 - 350 Per Kilogram

5000 Kilogram (MOQ)

Hdpe Welding Rod

Get Price Quote

HDPE welding rods are specialized thermoplastic rods used in the process of welding or joining High-Density Polyethylene (HDPE) materials. Here is a description of HDPE welding rods: Material Composition: HDPE welding rods are made from the same material as HDPE sheets or components. They are composed of high-density polyethylene, a durable and strong thermoplastic polymer. Compatibility: HDPE welding rods are specifically designed to be compatible with HDPE materials. This ensures optimal fusion and bonding during the welding process, resulting in strong and reliable joints. Form and Size: HDPE welding rods are typically available in the form of solid cylindrical rods. They come in various diameters and lengths to accommodate different welding requirements. Common diameters range from 3 mm to 6 mm, depending on the specific application. Color: HDPE welding rods are usually produced in a natural or translucent color. This color is similar to the natural color of HDPE material, allowing for a seamless appearance in welded joints.

Exothermic Welding Earthing Rod

4,500 - 5,500 Per Piece

1 Piece (MOQ)

Earth Rod Welded With Clamp

255 Per Piece

100 Piece (MOQ)

Welding Rods

150 - 300 Per Kilogram

2 Ton (MOQ)

Welding rods for shrinkage in casting effectively fill gaps and rectify defects caused by metal contraction. They guarantee robust, suitable for use with a wide range of metal alloys. Properties: Gap Filling Defect Rectification Seamless Repairs Strength

Welding Rods

Get Price Quote

We offer a variety of general purpose welding electrodes. These are being used in huge quantities by the fabricators, plant makers etc.

welded rods

Get Price Quote

308L (including ER308LSi) is predominately used on austenitic stainless steels, such as types 301, 302, 304, 305 and cast alloys CF-8 and CF-3. For high temperature applications such as in the electrical power industry, the high carbon 308H electrode provides better creep resistance than does 308L. 316L (including ER316LSi) filler metal should be used with 316L and 316 base metals. CF-8M and CF-3M are the cast equivalents of 316 and 316L, respectively. Use 309L (including ER309LSi) when joining mild steel or low alloy steel to stainless steels, for joining dissimilar stainless steels such as 409 to itself or to 304L stainless, as well as for joining 309 base metal. CG-12 is the cast equivalent of 309. Some 308L applications may be substituted with 309L filler metal, but 316L or 316 applications generally require molybdenum and 309L contains no molybdenum. Type 347 stainless steel filler metal is ideal for 347 and 321 base materials because it matches these stabilized grades. CF-8C is the cast equivalent of 347. Type 347 filler metal is also suitable most 308L filler metal applications.

Welding Rods

Get Price Quote

To rejoin plastic products is a tough task. For the same, we have introduced Plastic Welding Rods in varied specifications and colors to meet varied requisites of the application and clients. We are also listed amidst the most dependable Welding Rods Exporters and Suppliers in India. The use of optimum quality materials used in the manufacturing of the General Purpose Welding Rods ensure countable features like high durability and resistivity to various climatic conditions. Specification : Standard Size – 1 mm to 5 mm Color – All color

L&T EWAC Welding Rod

800 - 900 Per Pack

50 Pack (MOQ)

pvc welding rods

Get Price Quote

100 Kilogram (MOQ)

Welding Rods

1,500 - 2,500 Per Piece

1 Piece (MOQ)

Welding Rods

Get Price Quote

Our company manufactures top quality Mild Steel Welding Electrodes. The mild steel wielding electrodes offered by us are fabricated from X-ray quality mild steel and processed through technically adva.....

pvc welding rod

450 Per Kilogram

10 Kilogram (MOQ)

Welding Rods

Get Price Quote

HANDAZ-XL is our superior quality AWS-6013 welding electrodes. It is an ISI MARKED product. It is available in different sizes from 2.50mm to 5.50 mm.The benefits of using our electrodes are as follows1. Cost Effective.2. Very Low smoke & spatter.3. Strong and binding weld metal deposit.4. Uses very low amperes, thus saving of electricity.5. Smooth finish.6. Easy slag removal 7. Environment-Friendly.8. Works perfectly in all welding types and positions including vertical down.

Welding Rod

Get Price Quote

We are offering 904l welding rod. Brand available (aws specification) recommended applications weldfast 904l (e 385) welding of matching chemistry steel (sandvik 2rk65), suitable for production of organic acid, sea water cooling systems etc. Ampco-trode 10 (e cu al - a2) al bronze using smaw processes. Suitable for welding of cast iron, high and low carbon steels, copper, bronzes and copper-nickel alloys. Ampco-trode 40 (e cu mn ni al) suitable for welding of cast ship propeller conforming to mil-b-21230 used for high resistance to corrosion, erosion and cavitation. Also used for welding of dissimilar metals. Ampco-trode 46 (e cu ni al) suitable for welding of cast and wrought nickel- aluminum bronze. Cr-mo grades (imported brands such as kobe).

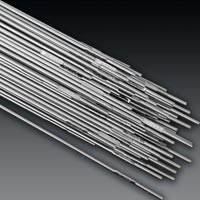

Stainless Steel Welding Rods

Get Price Quote

We are well-known Stainless Steel Welding Rods Supplier in India. The Stainless Steel Welding Rods, we offer, are acclaimed for features like excellent inter-crystalline corrosion-resistance, high strength, good blowhole-resistance and welding performance. The Stainless Steel Welding Rods, offered by us, are largely used for the production of equipment of synthetic fiber, chemical fertilizers, petroleum, etc. Specifications Diameter : 2.5 mm, 3.2 mm, 4.0 mm, 5.0 mm Length : 300 mm, 350 mm, 400 mm Features Wide melting range Low fluidity Reasonable cost Durable and reliable quality

silver brazing welding rod

Get Price Quote

We supply high quality Silver Brazing Welding Rods, which are available in different percentages and sizes. Procured from reliable vendors, these Silver Brazing Welding Rods are known for their superior quality. We offer Silver Brazing Welding Rods at market leading prices. Features : High conductivitySuperior performanceDurableAffordable prices

High-Quality Welding Rods

129 - 299 Per Kilogram

5000 Kilogram (MOQ)