wiped film evaporators

Get Price Quote

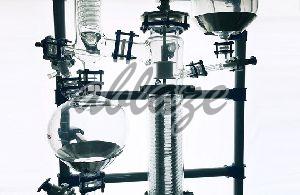

We are one of the corrosion resistant Wiped Film Evaporators Manufacturers based in India. Wiped Film Evaporator is a Thin Film Evaporator and consists of a jacketed glass / SS / other corrosion resistant pipe section in which is rotating a corrosion resistant PTFE / SS / other corrosion resistant wiper system with suitable rows of blades supported by suitable bearings. Wiped Film Evaporators give a high wiping frequency and therefore, an optimum renewal speed of the boundary layer, which are pre-requisites for thorough mixing of the liquid film and for high evaporation rates. The Thin Film Evaporators are forced against the evaporator wall by centrifugal force, and this can be varied via the speed of rotation of the drive, depending on the viscosity of the liquid. Inherent Features of Our Wiping Film Evaporators : Made of corrosion resistant materials Lowest possible working temperatures possible Very low residence time Visual observation while using Borosilicate glass Low Hold-up Modular system for all glass components that permits flexible design and rapid assembly of the unit Digital control of motor speed High level of automation (optional)

wiped film evaporator

500,000 Per Piece

1 Piece (MOQ)

Best Deals from Wiped Film Evaporator

wiped film evaporator

Get Price Quote

The TFE series Agitated Thin Film Evaporator has proven its efficiency as a device used for the distillation and the evaporation processes, where a scraper system is used to force the process of liquid film-forming. It can successfully undertake several unit operations together, such as defoaming reactions, deodorization, cooling, heating, and much more. Also, you can use it for the recycling process of the organic solvents found from industrial waste. The Agitated Thin Film Evaporator is commonly used in the food industry, pharmaceutical industry, light industry, environmental protection industry, petrochemical industry, and many more. Instrumental Features The scraper system pushes the liquid from a thin film through the rotation process, and hence it provides the appropriate evaporation efficiency and also reduces its operating time. The high-precision pipe made from glass allows the liquid to create a unified thin film over the hot surface. The Scraper system is built of SUS 316L and PTFE; all the other parts that come in contact with the liquid or gas are usually created from high borosilicate glass 3.3 and PTFE, as both the elements have an excellent corrosion resistance properties. The principle evaporation compartment is built from high borosilicate glass 3.3, which allows you to observe the process closely and clearly. You can control the temperature and keep it to the absolute level. The Agitated Thin Film Evaporator can reach up to 260°c temperature. We have a Self-cleaning roller Model film-forming system available with us. You can apply it to TFE-150, TFE-200, and TFE-300 models. We can make the most significant size up to DN300, which can help you reach an effective evaporation area of 0.6 meters Sq. A Self-cleaning roller Model, as well as the Scraper Model film-forming systems, are available with us. We also have Stainless steel material used in manufacturing the distillation barrels. Benefits of Wiped Film Evaporator or Agitated Thin Film Evaporator The Wiped Film Evaporator has a highly specific heat transfer capacity. It has a short residence time. It has a low-pressure drop capacity. It can operate under low vacuum scenarios. It has recorded the evaporation ratios up to greater than 95% without any recirculation. It is highly capable of processing high viscosity products. It is capable of processing the systems that create the deposits. It is super easy to clean. Applications of Wiped Film Evaporator or Agitated Thin Film Evaporator Wiped Film Evaporator can be installed to carry out the evaporation process without any mass transfer. It helps in moderating the evaporation ratios. You can apply or use the Wiped Film Evaporators for the viscous products. You can use it to feed the streams that contain solid particles. You can use the Wiped Film Evaporator to attain the high evaporation ratios of almost more than 95%. It can be applied to stripping.

wiped film evaporator

Get Price Quote

We are a reliable Manufacturer, Exporter and Supplier of Wiped Film Evaporator in Vadodara, Gujarat. Our Film Evaporator is highly demanded by our valued customers due to its supreme quality. We can make available Film Evaporator with customized technical specifications in order to satisfy our valued customers. Our Wiped Film Evaporator is available in different sizes and quantities at the most reasonable prices in the market. Description : Super offers jacketed reactors in all glass construction; jacketed reactors with glass lined steel, and jacketed reactors in Stainless steel. In all the cases the overhead equipment such as condensers, reflux dividers, receivers and piping components are of borosilicate glass. Borosilicate glass Spherical vessel (Cylindrical vessel could be offered on request) Borosilicate Glass flush bottom outlet valve Drive assembly with flame-proof motor Agitator shaft sealing with bellow type PTFE single mechanical dry running seal Borosilicate Glass thermometer pocket Borosilicate Glass dip pipe / sparger Electrical Heating mantle with temperature regulator Coil type heat exchanger The system is provided with the following instrumentation in a flame proof enclosure: Reaction mass temperature indicator (digital) Vapour temperature (Digital) Pressure / vacuum indicator (Digital) The reactor and the associated glass components are installed on Stainless Steel tubular supporting structure. This structure is highly versatile and flexible. Any later additions can be effected without difficulty.

wiped film evaporator

Get Price Quote

1 Piece(s) (MOQ)

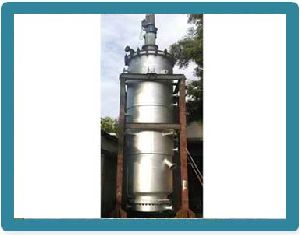

Rely on us for premium quality of the products as we make use of the finest grade raw material for preparing them. Also, we procure it from the reliable places after complete quality satisfaction. With the assistance of skilled professionals and high-grade packaging system, we can easily furnish customized packaging requirements of the customers. Features : Precision engineered Advanced technology Easy to maintaing

wiped film evaporator

Get Price Quote

We have parted our infrastructure into different units and one of them is warehouse wherein we keep our product lot for meeting urgent and bulk requirements of the buyers at a time. Our organization is graded among receptive and responsible Suppliers of Wiped Film Evaporator, involved in providing to purchasers across diverse marketplaces.

wiped film evaporator

Get Price Quote

We are one of the trusted companies in India, which is manufacturer and exporter of Wiped Film Evaporator. The system we provide is based on latest technology, which is mechanically designed and tested by our engineers so that it can give the best of its performance. Our system is fully customized to meet our client’s requirement.Wiped Film Evaporator is a Thin Film Evaporator and consists of a jacketed glass / SS / other corrosion resistant pipe section in which is rotating a corrosion resistant PTFE / SS / other corrosion resistant wiper system with suitable rows of blades supported by suitable bearings.These give a high wiping frequency and therefore, an optimum renewal speed of the boundary layer, which are pre-requisites for thorough mixing of the liquid film and for high evaporation rates. The wipers are forced against the evaporator wall by centrifugal force, and this can be varied via the speed of rotation of the drive, depending on the viscosity of the liquid.Features : Made of corrosion resistant materials. Lowest possible working temperatures possible. Very low residence time. Visual observation while using Borosilicate glass. Low Hold-up. Modular system for all glass components that permits flexible design and rapid assembly of the unit. Digital control of motor speed. High level of automation (optional)

wiped film evaporator

400,000 - 800,000 Per Unit

1 Set(s) (MOQ)

wiped film evaporator

Get Price Quote

wiped film evaporator

Get Price Quote

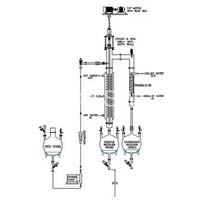

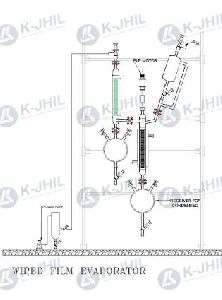

Agitated thin film evaporator (also commonly referred to as a "Thin Film or wiped film evaporator") consists of two main parts: a cylindrical jacketed body which is heated by means of steam or thermic fluid and a rotor inside the cylindrical tube. Product is introduced above the heated zone on a distributor plate. This distributor plate evenly transfers the liquid over the evaporator's inner surface. As the product spirals down the wall, the high rotor tip speed generates centrifugal force and due to low clearance between rotor blades and cylinder inner surface, it creates thin film. This thin film and heated surface create optimum heat flux and mass transfer conditions. Volatile components are rapidly evaporated via conductive heat transfer. Vapours flow either counter-currently or co-currently through the unit, depending on the application requirements. The vapours are passed through condenser and collected. Residual components are discharged at the outlet. Continuous agitation and mixing by the rotor blades minimizes fouling of the thermal wall where the product or residue is most concentrated. Advantages are less residence time, can handle heat sensitive materials and lesser space requirement.

wiped film evaporator

Get Price Quote

agitated wiped film evaporator is best suitable for heat sensitive product where product drying time and drying temperature are very critical and well acknowledged among the buyers..

wiped film evaporator

Get Price Quote

We are offering wiped film evaporator. The wiped film evaporator is used for concentration, distilling, stripping, dehydration and deodorisation of products which are heat sensitive or viscous. The equipment can handle a very wide range of feed compositions ranging from 1% to over 95% concentration. Wfe has several advantages as stated in the table below. The operation is continuous with a single pass; the self cleaning continuous contact wipers produce and renew the thin film. Such an operation improves product yield, avoids residue and colour formation. It has an internal condenser (optional) that minimizes the pressure drop and maintains vacuum

wiped film evaporator

Get Price Quote

Wiped Film Evaporator is designed to handle challenging evaporating requirements with materials that are heat-sensitive, highly viscous, or of low thermal conductivity. This technology involves separating volatile compounds by introducing a mechanical agitated thin film of feed material to a heated surface.

wiped film evaporator

1,000,000 Per Piece

wiped film evaporator

Get Price Quote

Wiped film evaporator is passed through the jacket of the shell thereby heating the internal surface of the shell to required temperature. The liquid feed is introduced at the top and spread across the shell internal by the rotating distributor. The agitator blades while rotating spread the liquid on the heated shell surface causing the evaporation of the solvent or water and the concentrated product is discharged at the bottom. If the feed contains solvent the evaporator is operated under vacuum and the vaporised solvent is passed through a condenser to recover the solvent.

wiped film evaporators

Get Price Quote

From Tamil Nadu, we are among the high-standing Manufacturers, Suppliers and Exporters of the Wiped Film Evaporators’ unbeaten range across the globe. Precisely constructed as per the industry laid standards, these Wiped Film Evaporators are most suitable for the heat sensitive materials. For client’s convenience, we offer the quality-assured Wiped Film Evaporators in the desired stipulations. Place order with us; medium or bulk & avail discounted offers. Specifications : Least residence time in heating one. Avoid over heating of the products. Inter cooler causes the immediate condensation of vapor hence no deterioration of distillate. Agitated Thin Film Evaporators High heat transfer.

wiped film evaporator

Get Price Quote

We manufacture and supply wiped film evaporators / agitated Thin Film Evaporator.

wiped film evaporator

Get Price Quote

Introduction The Wiped Film Evaporator is used for concentration, distilling, stripping, dehydration and deodorisation of products which are heat sensitive or viscous. The equipment can handle a very wide range of feed compositions ranging from 1% to over 95% concentration. WFE has several advantages as stated in the table below. The operation is continuous with a single pass; the self cleaning continuous contact wipers produce and renew the thin film. Such an operation improves product yield, avoids residue and colour formation. It has an internal condenser (optional) that minimizes the pressure drop and maintains vacuum.

wiped film evaporator

Get Price Quote

Our Wiped Film Evaporator are used to flash distill heat sensitive materials having various components under controlled temperature at atmospheric pressure or under vacuum whilst maintaining short residence time so as to prevent localized heating and thermal decomposition of the material.

wiped film evaporators

Get Price Quote

Most suitable for heat sensitive materials. Least residence time in heating one. Avoid over heating of the products. Inter cooler causes immediate condensation of vapor hence nodeterioration of distillate. Agitated Thin Film Evaporators High heat transfer coefficient. Less residence time. Falling Film Evaporators Handles more volume of solvents. Economical for pre concentration. Rising Film Evaporators or Forced Recirculation Evaporators High heat transfer co-efficient. Suitable for medium solid concentration.