PVC Insulated Submersible Pump Cable

25 Per Meter

Hi Tensile Barbed Wire

5,500 - 5,900 Per Roll

10 Roll (MOQ)

Best Deals from Wires

Brass Wires

70 - 80 Per Kilogram

500 Kilogram (MOQ)

Flat Cables

Get Price Quote

We are instrumental in offering to the clients Flat Cables that are manufactured using high quality electro metric materials. These Flat Cables are offered in varied capacities, designs and specifications. Moreover, we also customize the Flat Cables as per the specifications and requirements of the clients.Our customers can avail from us superior grade Flat Cables. The cables offered by us are manufactured by our skilled professionals by making use of modern machines and tools. Our vendors facilitate us with high quality materials, which are used to manufacture top-class cables. These cables are used for wiring electrical appliances and machines. Keeping in mind the various requirements of our customers, we are able to offer these Flat Cables in many lengths.Features: High conductivity Heat resistant Water proof Durable

Stainless Steel 904L Wire

1,500 - 1,550 Per Kilogram

5 Kilogram (MOQ)

Sankalp Alloys Overseas is a reliable creator, producer and supplier of the best SS 904L wires. Under the bearing of experienced specialists, these wires are conveyed using premium-grade normal substances got from trustworthy dealers. Our things are of the best quality and viable. We offer ideal movement in a serious period.These Stainless Steel 904L wires offer different benefits due to the impressive characteristics of the blend. These SS 904L wires have extraordinary assurance from high-temperature conditions containing moderate sulfur parts. Moreover, this steel 904L wire shows appealing permeability. These wires can be welded by standard welding cycles, and they give strong assembling features. They perform well in raised temperatures. Incredible SS 904L wires enjoy wonderful benefits like extraordinary disintegration resistance, pitting hindrance, and oxidation check. The wires give more useful properties like strength, incredible layered accuracy, constancy, and world class execution. These wires are impenetrable to push disintegration breaking and gap utilization.Stainless Steel N08904 Welding Wire, Competitive Price Of Stainless Steel 904l Wires, Stockist Of Asme Sa 580 904l Ss Spring Wire Mumbai, N08904 Stainless Steel Wires Trader, Ss N08904 Wire Bobbin, Stainless Steel 904l Coil Wire, Ss 904l Cold Heading Wire, Stainless Steel 904l Wire Rope, Ss 904l Bright Wires, Stainless Steel 904l Wires Exporter In India.SPECIFICATION OF SS 904L (UNS N08904) WIRE SPECIFICATIONS: ASTM A580 ASME SA580 / ASTM A313 ASME SA313, AMS 5514 WIRES DIAMETER: 0.0004" to 0.040" 10 microns to 1.0 mm Other Sizes on Request STANDARDS: DIN, ASTM, ASME, BS and all International Standards Wire Density: 8.89 g/cm3 DIMENSIONS: ANSI/AWCI – 01 -1992 and ASTM E 2016-11 and RRW 360 ULTIMATE STRENGTH (≥ MPA): 580-750 LENGTH: Cut Lengths: 0.125" to 72" No Limit on Spooled Lengths WIRE RESISTANCE (ΜΩ.M): as standard TEMPERS: Tempers range from dead soft annealed to ultra spring temper WELDED WIRE MESH: Roll Width: 24inch, 36inch, 1Metre, 48inch, 72inch, or 84inch Roll Length: 100feet or 150feet WIRES MESH WEAVING METHODS: plain weave, twill weave, dutch weave WIRE TECHNIQUE: Cold Rolled, hot rolled

Aluminium Electrical Wire

Get Price Quote

10 Roll (MOQ)

Wires and cables are the most effective devices for transferring electrical current and communication signals in any electrical circuit. Your electrical appliance precautions are now better thanks to the best wires and connections that S3 Engineers as Aluminium Electrical Wire Suppliers can provide. S3 Engineers can end your incredible search for a wide selection of Wires & Cables in India in different types and brands all at one location. We are committed to providing consumers with the greatest brands and goods at the best rates as one of the leading suppliers, dealers, and distributors of electrical equipment online in India. Our catalogue is designed with user-friendly features that let you rapidly select things from your wish list so that you can start your online shopping right away.

Shaped Profile Wires

Get Price Quote

500 Kilogram (MOQ)

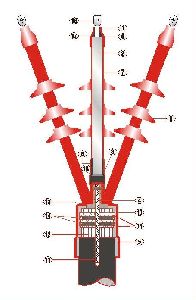

YXO/E-1524 Series 3 Core Insulation Cable

Get Price Quote

CTL Electrical Heat Trace Cables

Get Price Quote

Our company is a renowned CTL Electrical Heat Trace Cables Manufacturer, Exporter and Supplier from Haryana (India). The CTL Electrical Heat Tracer is used to maintain product temperature inside vessels, tanks, pipeline or equipments. It keeps viscous fluids in flow state avoiding choking of pipelines. Our CTL Electrical Heat Tracer is a constant wattage, parallel circuit heat tracer comprising twin parallel bus wires of multistrand copper. It is insulated with PTFE or Silicon Rubber or LSZH, depending on the temperature application. Types : CTL PT Electrical Heat Tracer (PTFE insulated) and CTL SR Electrical Heat Tracer (Silicon Rubber insulated) is positioned to serve virtually in every process industry - Oil & Gas, petrochemical, power, chemicals & fertilizers, metallurgical, cement, pharmacy, food and edible oil industries. CTL-ZH Electrical Heat Tracer (Polyolefin insulated) finds application for freeze protection in the Refrigeration industry.

Black Annealed Wire

62,000 - 75,000 Per Metric Ton

1 Metric Ton (MOQ)

Silver Alloy Wire

90,000 Per

10 Kilogram (MOQ)

Aluminium Rivet Wires

220 Per Kilogram

200 Kilogram (MOQ)

3.5 Core Aluminium XLPE Armoured Power Cables

Get Price Quote

100 Meter (MOQ)

Lead Wire

180 Per Meter

1000 Meter (MOQ)

Copper Coated Wires

Get Price Quote

copper coated ms filler wire

Stitching Wires

Get Price Quote

Plastic Heald Wire for Water Jet Loom

5 Per Piece

1000 Piece(s) (MOQ)

We are leading mfg and exporter of plastic heald wire for water jet loom suitable for textile jacquard machine.

2 Core Armoured Cable

30 - 1,200 Per Meter

100 Meter (MOQ)

Concertina Wire

500 - 1,500 Per Coil

50 Coil (MOQ)

PET Black Wire

85 Per Kilogram

1000 Kilogram (MOQ)

Stainless Steel Wire

Get Price Quote

10 Kilogram (MOQ)

Stainless steel wire, two wires twisted togwther for max strenght. multiple thickness, multiple sizes available.

Fire Alarm Cable

40 - 80 Per Meter

100 Meter (MOQ)

FRLS 1.5 Sq. mm Armoured Cable used in Fire Alarm System Colour- RED

2 Core Transparent Speaker Wire

28 Per Meter

2000 Meter (MOQ)

Barb Wire

Get Price Quote

Providing quality Barbed Wire in Raipur have strengthened our business and made us able to reach the heights of success. Till now, the company has outmatched its competitors and achieved a competitive edge worldwide. Ensured according to latest industrial standards & norms, we offer excellent Barbed Wire in Raipur that is usually renowned due to its exclusive features like durability, various coating colours, easy to handle, and robust construction.

Blue Multi Strand Wire

325 Per Roll

50 Roll (MOQ)

PTFE Insulated Heating Wires

Get Price Quote

500 Meter (MOQ)

We offer the best quality heating cables made of the premium quality materials. The latest technology is used in the manufacturing process of the products to mage them durable to the highest extent. The underfloor heating cables are efficient enough for under-floor wiring. The insulated heating cables are insulated properly to ensure total safety. That is why, we are counted among the leading exporters of heating cables by supplying the products of international standard in terms quality, durability and performance.

CCTV Cable

Get Price Quote

We offer precision engineered CCTV Cable designed and developed by the experts in compliance with international standards. Our CCTV Cable is strictly tested on various parameters of quality by which we guarantee for its performance and efficiency. Brand Name : POLY UNIFLOW Salient Features Rugged construction Suitable for virtually any installation Available with proper ends Long life Made To Connect your CCTV Surveillance Cameras to any of your DVR, VCR, or PC Based DVR System. Specifications TYPES COAXIAL CONTROL CABLES Inner Conductor 7 x 0,19¸ mm Stranded Tinned Copper 16 x 0,20mm Section : 0,50 mm2 + 14 x 0,15¸ mm Section : 0,25 mm2 Stranded Tinned Copper Insulation 2,10 mm FOAM PE¸ 1,50 mm PVC + 1,20 mm PVC Screen Tinned Copper Braid 85% Coverage Al-Foil Shielded 100% Coverage Outer Sheath PVC Gray RAL 7001 Min. Bending Radius 15 x Cable Diameter Standard Packing 100. -m Roll / 500 m Wooden Spool

Annealed Fuse Wire

Get Price Quote

Aluminum Wire

Get Price Quote

1 Core PVC Coated Binding Cable

72 Per Meter

500 Meter (MOQ)