Customised Precision Wire Cut Components

Get Price Quote

100 Piece (MOQ)

Customisation is available

Wire Bending Component

3 - 15 Per Piece

500000 Piece (MOQ)

Best Deals from Wiring Components

Wire Components

Get Price Quote

With the assistance of our highly skilled professionals, we are engaged in offering Wire Components to our clients. Our offered product is specially designed to fulfill the needs of several industries. These are available in various specifications, to suit the variegated industrial applications. We are well-capacitated to deliver them in bulk quantities, within the promised time frame. We offer them at competitive prices to our esteemed costumers.

Brass Wiring Components

Get Price Quote

100 Piece (MOQ)

Automotive Wire Lever

Get Price Quote

wiring harness components

Get Price Quote

We deal in components required for wiring harness. We are the importers of connectors, terminals and other components of ket, tyco etc

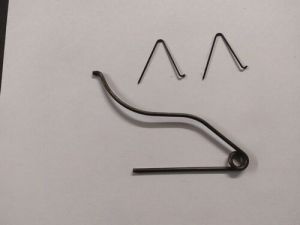

wire bending

5 - 12 Per pieces

1000 pieces (MOQ)

Wire bending is a specialized manufacturing process that involves the manipulation of wire or metal rods into various shapes and configurations, often with precise angles and curves. This technique is widely used across multiple industries, from automotive to electronics, construction, and crafts. Here is a detailed description of the wire bending process: 1. Diverse Applications: Wire bending is employed in numerous applications, including the creation of wire forms, springs, custom hooks, fasteners, decorative elements, and intricate components for machinery and appliances. Its versatility allows it to adapt to a wide range of industries. 2. Materials: Wire bending can be applied to various materials, including steel, stainless steel, aluminum, copper, and even plastic or composite materials. The choice of material depends on the specific application's requirements, such as strength, corrosion resistance, or electrical conductivity. 3. Precision and Customization: One of the key advantages of wire bending is its ability to achieve precise and customized shapes. Advanced bending machinery and computer numerical control (CNC) technology enable the production of intricate and highly accurate wire components to meet exact specifications. 4. Bending Techniques: Wire bending can be accomplished using a variety of techniques, including manual bending, semi-automated machinery, and fully automated CNC bending machines. CNC technology allows for the efficient production of complex wire shapes with consistent precision. 5. Wire Diameter and Thickness: Wire bending can accommodate a wide range of wire diameters and thicknesses, from fine, delicate wires used in jewelry to thick, robust wires employed in industrial applications. The bending process is adjusted to suit the specific wire characteristics. 6. Tools and Dies: Specialized tools and dies are used to shape the wire accurately. These tools are designed to create bends, loops, angles, and curves according to the desired design or engineering specifications. 7. Quality Control: Quality control measures are implemented to ensure that each bent wire component meets the required standards. This includes checking for dimensional accuracy, uniformity, and the absence of defects. 8. Efficiency and Speed: Automated wire bending machines can produce large quantities of bent wire components quickly and efficiently, making it suitable for high-volume manufacturing processes. 9. Versatility in Industries: Wire bending is found in a wide range of industries, such as automotive, aerospace, electronics, construction, medical devices, and consumer goods. It is used in everything from wire harnesses in cars to intricate springs in electronics. 10. Customization and Prototyping: - Wire bending is particularly valuable for prototyping and small-batch production, as it allows for rapid customization and adjustments to design changes without the need for expensive tooling. In summary, wire bending is a versatile manufacturing process that transforms wire or metal rod materials into precise and customized shapes to meet the demands of various industries. Its adaptability, precision, and efficiency make it a valuable technique in the creation of wire-based components and products, from simple wire forms to intricate mechanical parts. Description of Wire Bending Wire bending is a specialized manufacturing process that involves the manipulation of wire or metal rods into various shapes and configurations, often with precise angles and curves. This technique is widely used across multiple industries, from automotive to electronics, construction, and crafts. Here is a detailed description of the wire bending process: 1. Diverse Applications: Wire bending is employed in numerous applications, including the creation of wire forms, springs, custom hooks, fasteners, decorative elements, and intricate components for mach

Vespa Bajaj Classic SL Chetak 99 Magnet Wire Component

10 Per Piece

Vespa Bajaj Classic SL Chetak 99 Magnet Wire Component Fit Vespa Bajaj Classic SL Chetak 99 Models ISO 9001:2008 Certified High Quality | Best Performance | MGE Trust

Sheet Metal Wire Components

Get Price Quote

We bring forth a wide array of Sheet Metal Wire Components from Punjab. The Sheet Metal Wire Components offered by us are manufactured in adherence with international quality standards. High durability, abrasion resistance and strength are some of the attributes of our Sheet Metal Wire Components. Rigorous quality-tests ensure that only defect-free Sheet Metal Wire Components reach the buyers. Our company is a renowned Manufacturer, Supplier and Exporter of Wire Components from Punjab.

cnc wire cut machine components

Get Price Quote

We are offering cnc wire cut machine components. We use high-quality materials to fabricate cnc wire cut machine components. Additionally, our professionals utilize the latest techniques to make cnc wire cut machine components. Clients can avail cnc wire cut machine components in required specifications from us. We are a preeminent cnc wire cut machine components manufacturer and supplier in ludhiana (india). highlights better production outputcompact designhigh performanceuser-friendly operationsturdy constructionless power consumptioneasy maintenanceextreme strength.

CNC Wire Cut EDM Components

Get Price Quote

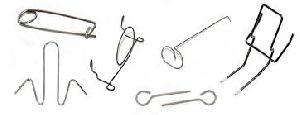

Wire Forming Components

Get Price Quote

The company is a well-known Manufacturer, Supplier and Exporter of Wire Forming Components. We specialize in steel wire forming using spring wires in diverse shapes such as flat, round, square & rectangular. We use a variety of metals ranging from steel & copper, to annealed materials, bronze, & alloys, as per needs. Our trained wire forming specialists as well as the use of precision machines are capable of providing Wire Forming Components in varying dimensions depending on the material or the specific requests of customers. Technical Specifications Wire thickness : 0.1 to 10 mm wire thicknessMetal : iron, high carbon steel, stainless steelWire forming components : 0.10 mm to 15 mmWire forming components : 0.10 mm to 15 mm

Wire Bending Component

Get Price Quote

Wire Bending Component

150 Per Piece

wire component

Get Price Quote

Balled Tungsten Wire Components

Get Price Quote

Balled Tungsten Wire Components We have good capability to manufacture and supply Tungsten & Molybdenum Formed Wire Parts (used in Electro-Surgical Devices) at economical prices.

Wire Bending Components

Get Price Quote

An ISO 9001-2008 Certified Company, we make available the Wire Bending Components at market leading prices. The Wire Bending Components we offer is manufacture using high-grade raw material and under the supervision of experts. We only offer the Wire Bending Components that are durable, sturdy and are precisely designed and developed. We are capable of fulfilling the bulk requirements of customers all over the world.

Wire Bending Component

Get Price Quote

Wire Bending Component

10 Per Piece

Wire Bending Component

80 Per Piece

Electrical Brass Components / Electrical Wiring Accessories

Get Price Quote

Electrical Appliance ComponentsContact Block Lock Brass PartsElectrical Insulating ComponentsElectrical ConnectorsAuto Electrical Parts And EquipmentsElectrical Fuse ConnectorsElectrical TerminalsElectrical PinsElectrical Valve PinsElectrical Cord PinsElectrical SocketsPlastic Moulding PartsInserts For MouldingBrass Electrical Earth Pins Brass Terminal For Telecommunication Telephone PartsAutomotive Electrical PartsSwitch Gear AccessoriesPlastic Electrical Industry ProductFixing InsertsGear ComponentsIndustrial ComponentsBrass Sheet Cutting ComponentsHose FittingsPipe FittingsEarthing AccessoriesPanel Board AccessoriesBrass AnchorBrass HingesNeutral LinksTerminal BlocksBattery Terminals Product Details: SOHAM PreciMek [INDIA], manufacturing all kind of electrical brass components and electrical wiring accessories for many applications. We produce components as per customer’s requirement which change accordingly customer application.We export brass components to USA, UK, France, Italy, Australia, Spain, Mexico, Bulgaria, Poland, Greece and German country.

wire edm components

Get Price Quote

Sterling Silver Wire Guardians

Get Price Quote

Sterling Silver Wire Guardians are meant to protect wire from getting damaged by clasps or other sharp components used in jewellery making.

wire form components

Get Price Quote

Cables and Wiring Components

50 - 60 Per

1 Piece (MOQ)

Cables and Wiring Components, MAX30100 Pulse Oximeter Heart Rate Sensor Module

Wire Forming Components

Get Price Quote

Wire Forming Components, Press Tools, Hard Disk Holder Plate

wire forming sheet metal components & filter inserts

Get Price Quote

wire forming sheet metal components & filter inserts, Springs, Coils

Wire Bending Components

Get Price Quote

An ISO 9001-2008 Certified Company, we make available the Wire Bending Components at market leading prices. The Wire Bending Components we offer is manufacture using high-grade raw material and under the supervision of experts. We only offer the Wire Bending Components that are durable, sturdy and are precisely designed and developed. We are capable of fulfilling the bulk requirements of customers all over the world.

Wire Rod Finishing Components

Get Price Quote

UGI Engineering has extensive portfolio of equipment to cover the complete range of final processing needs. From counting to bundling and stacking – every thing can be arranged for a smooth final production process.

industrial wire form components

Get Price Quote

industrial wire form components, Sheet Metal Components, Torsion Springs