Spiral Tension Wound Crimped Fin Tubes

Get Price Quote

Spiral crimped finned tubes are manufactured at TAAM engineering on specially developed high speed finning machines. Our machines are capable of finning tubes in lengths up to 18 meters (60 feet). We make finned tubes with base tubes of carbon steels, stainless steels, copper and copper alloys like cupro-nickels, admiralty brass, aluminum brass with copper fins, stainless steel fins and GI (galvanized iron) fins. The base tubes of our standard edge wound crimped fin tubes range from 16 mm to 25.4 mm with fin heights ranging from 3 mm to 13 mm.

Crimped Fin Tube (Spiral Tension wound Fin Tube)

5,001 Per Meter

10 Piece (MOQ)

Best Deals from Wound Tube

-Spiral Wound Finned Tube

200 Per Meter

10 Number (MOQ)

We are the manufacturer of Spiral Finned tubes

Spiral Wound Finned Tube

Get Price Quote

Filament Wound Epoxy Tubes

Get Price Quote

100 Kilogram (MOQ)

Wire Wound Finned Tube

Get Price Quote

Our Wire Wound Finned Tube are constructed out of wire loops soldered to the base of the tube and come with an enhanced turbulence feature thus ensuring proper cleanliness. These are excellently designed by our efficient team to incorporate a high heat transfer design and excellent quality. The material used for manufacturing these tubes is premium quality copper, brass and cupro nickel for base and tinned copper for wire winding.

LEVEL WOUND COPPER COIL Copper Tubes

Get Price Quote

Level Wound Coil (LWC) Copper Tubes feature minimum copper content of 99.9% as per IS-191 and are available in Forged / Hot Rolled / Extruded as well as Cold Worked finish in different dimensions and specifications. These are also available in hard, half-hard as well as soft conditions. As the tubes comprise de-oxidized copper, it is not affected through reducing atmosphere and is well suited for welding and brazing applications. Applications Areas: Application Areas are not just limited to the below mentioned uses. Copper Coil has a vast usage in today’s dynamic world.

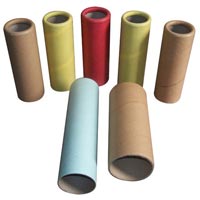

spiral wound paper tubes

Get Price Quote

We are engaged in manufacturing and supplying of Spiral Wound Paper Tubes in all over India. We provide these Spiral Wound Paper Tubes in a wide range of sizes to address many common industrial packaging applications, as per the customers� demands. The Spiral Wound Paper Tubes can be availed from us at affordable prices. Made From Craft PaperCone boardParchment paperVarious type of Glues Used In Paper millsPharmacies Yarn spinningMachinery part manufacturing unitsCello & BOPP tape manufacturing units

Wound Paper Tubes

Get Price Quote

10000 Piece(s) (MOQ)

We are offering Wound Paper Tubes to the global market at ineffective rates. Our company is one of the distinguished Manufacturers, Exporters and Suppliers of Wound Paper Tubes from Himachal Pradesh, India. We are making available a variety of Tubes in different thickness, designs, colors, and sizes for the market. In addition, we abide by the international standards of quality while manufacturing Wound Paper Tubes. Buyers can obtain Customized Paper Tubes that are wounded either from one side or from both sides.

wire wound fin tubes

Get Price Quote

We are one of the largest Wire Wound Fin Tube Manufacturers in India . Wire Wound Fin Tube is our star product becauseof its superior efficiency. It consists of wire loops wound that are Solder bonded to the external surface of a round tube.The variable density of wire loops allows for optimal thermal selection. With our flexible manufacturing process these tubeare now very cost effective for both small and large volume applications.

wire wound finned tubes

Get Price Quote

The range of the Wire Wound Finned Tubes is offered in several sizes and dimensions as well as varied technical specifications. The longer service life makes the array of the Wire Wound Finned Tubes reliable, and high heat transfer efficiency is ensured as well. The company stands tall as a Manufacturer and Supplier of Wire Wound Finned Tubes.

wire wound fin tubes

Get Price Quote

Our company is well-reckoned as renowned Manufacturer, Exporter and Suppliers of precision-engineered Wire Wound Fin Tube. Made using CAD/ CAM technologies and premium raw materials, our Wire Wound Fin Tubes are the best in the market. They are robust, corrosion resistant and durable. We guarantee our Wire Wound Fin Tubes will retain their physical properties even under extreme conditions. Buyers can purchase Wire Wound Fin Tubes from us at market leading prices as per requirement.

Level Wound Coil Copper Tubes

100 - 150 Per Kilogram

200 Kilogram (MOQ)

Helical Tension Wound Finned Tubes

Get Price Quote

Backed by our eminent workforce, we are able to manufacture, supply and export finest grade Helical Tension Wound Finned Tubes. These Helical Tension Wound Finned Tubes are appreciated by our clients for their durability, dimensional accuracy and excellent finish. The offered range of Helical Tension Wound Finned Tubes is manufactured by our dedicated workforce following set manufacturing procedures. Moreover, these Helical Tension Wound Finned Tubes are tested on certain well-define parameters set by the industry to make sure zero manufacturing defects. Features : Dimensionally accurate Robust construction Durable Corrosion resistant

Filament Wound Tubes

Get Price Quote

We are engaged in offering comprehensive range of FRP Filament Winding Tubes that is manufactured using the best quality of raw material. Our tubes are produced using a filament wound technique that gives the tube, both hoop and axial strength. ARC FRP tubes have high durability, high stability and high performance. We do complete quality checking of these Filament Winding Tubes to ensure quality and durability. Our FRP Filament Winding Tubes also find use in Waste Water/Pollution Control Petro Chemical Cooling Towers Oil Air/Ventilation Water Fume Extraction Transport

Carbon Fiber Fabric wound Tubes

Get Price Quote

50 Piece(s) (MOQ)

We are offering carbon fiber fabric wound tubes. Carbon fiber has a negative coefficient of thermal expansion, meaning it expands as the temperature lowers. The resin matrix, on the other hand, has a positive coefficient. The net result is virtually no expansion or contraction of the composite over a wide range of temperatures. Advantages • light weight • high tensile strength • high modulus of elasticity • corrosion resistance • very high strength • low thickness application • reduce pollution

Wire Wound Tube

Get Price Quote

spiral wound paper tubes

5 Per Piece

5000 Piece (MOQ)

Filament Wound Carbon Fiber Tube

2,000 - 5,000 Per rs

Spiral Wound Paper Tube

35 Per Kilogram

1 Container (MOQ)