Woven bags printing plate making machine.

354,000 - 354,001 Per Piece

Currently, we are manufacturing Flexography photopolymer plate making Equipment, including Rubber Stamp Making Equipment, Letterpress Plate Making Equipment, pad printing photo polymer plate making equipment, Label photo polymer plate making equipment , Varnish photo polymer plate making equipment, Flexo Solvent Recycling unit, Liquid Resin Stamp making equipment, Nylon Block making equipment , Water Wash photo polymer plate making equipment , Flexo plate making equipment, Flexo photo polymer plate making machine All type of stamp making series , Embossing plate making equipment, Pharmaceutical Batch plate making equipment, Woven sack photo polymer plate making equipment, flexo photo polymer die making machine , flexo photo polymer block making machine , photo polymer batch coding machine , flexo stereo photo polymer plate making machine , and all type photo polymer plate making machine series …….for flexographic printing ..

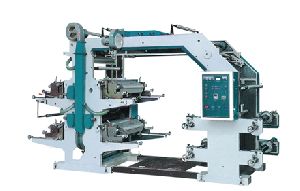

Woven Bag Roll to Roll Printing Machine

Get Price Quote

01 Set(s) (MOQ)

We are offering woven bag roll to roll printing machine. We at fuma have put all our efforts into making each of our machines the best of its kind. We manufacture printing machines up to six colors. Multi color can be combined freely by changing the direction of cloth threading. When machine stops, the ink transmission mechanism will work continuously and wait for re-start. It can reduce forming waster. Each color can be controlled separately. feature • excellent price – performance ratio. • exceptionally reliable and accurate • very compact and high end technology. • easy maintenance and operator friendly design. • both type of winders offered – machinical and turret. • auto tension control system for unwinder. • perfect registration of print • in-line perforation unit offered as option. • up to 100 mtrmin speed of printing and cutting. • up to 800 mm printing width and up to 1000 mm cutting length. • individual gearbox with inbuilt plenetary system at each printing station. • special designed anilox and ink roller for maximum milage and minimum splashing of ink at higher speed. • both type of ink drying option offered – hot air and infrared heaters. • offered vertical gusseting system as optional. • central control cabinet with ac drive system. • for roll to roll printing, surface winder also offered optionally. • available with both type of bag cutter – for laminated and for unlaminated. • igbt technology based latest corona treater.

Best Deals from Woven Bag Printing Machine

Woven Bag Printing Machine

Get Price Quote

We are offering woven bag printing machine. a flexographic print is made by creating a positive mirrored master of the required image as a 3d relief in a rubber or polymer material. flexographic plates can be created with analog and digital platemaking processes. The image areas are raised above the non image areas on the rubber or polymer plate. The ink is transferred from the ink roll which is partially immersed in the ink tank. Then it transfers to the anilox roll (or meter roll) whose texture holds a specific amount of ink since it is covered with thousands of small wells or cups that enable it to meter ink to the printing plate in a uniform thickness evenly and quickly (the number of cells per linear inch can vary according to the type of print job and the quality required).[5] to avoid getting a final product with a smudgy or lumpy look, it must be ensured that the amount of ink on the printing plate is not excessive. this is achieved by using a metal scraper, called a doctor blade. The doctor blade removes excess ink from the anilox roller before inking the printing plate. The substrate is finally sandwiched between the plate and the impression cylinder to transfer the image.[6] the sheet is then fed through a dryer, which allows the inks to dry before moving on.in the case a uv ink is used, the sheet does not have to be dried, but is dried from uv rays. basic parts of the press unwind and infeed section"- the roll of stock must be held under control so the web can unwind as needed printing section- single color station including the fountain, anilox, plate and impression rolls drying station- high velocity heated air, specially formulated inks and an after-dryer can be used outfeed and rewind section- similar to the unwind segment, keeps web tension controlled.

Woven Bag Printing Machines

140,000 Per Piece

1 Piece (MOQ)

Woven Sacks Bag Flexographic Printing Machine

Get Price Quote

Buy from us a huge range of sturdy and high performing Woven Sacks Bag Flexographic Printing Machine that are widely used for packaging and labeling printing. These machines supply an excellent ink transfer and coverage that guarantees in best printing result. Ink is then evenly transmitted to the photo polymer on plate mounting which print directly to the application. Ink is design to meet the hardest wash resistance and can also replace screen printing to print solid white in black. Features: Resistant to corrosion & wearing Quality tested High performance

Flexographic Printing Machine 6 Colors for HDPE Woven Sack Bags

Get Price Quote

Our Company. Flexo India offers wide range of high quality HDPE Woven Sack and Non Woven Bag Printing Machines. The offered Machines include 8 Colour HDPE Woven Sack Flexo Bag Printing Machine, Flexo Printing Machine, Flexo Printing Machine for HDPE and Woven Sack Bags etc. and Non Woven Bag Printing Machines are as, 6 Colours High Speed Flexographic Printing Machine, Non Woven Flexographic Printing Machine 2 Colours etc. We use superior grade raw material and components, procured from the reliable and certified vendors of the industry. Further, these machines are manufactured under the expertise supervision of our highly qualified and experienced professionals of the company. This facilitates us to offer world class Machines at the industry leading prices. The Special Features of our Machine is as under:● Cost Effective,● Longer Service life.● Energy Efficient,● Robust in Construction● High Speed,

PP Woven Bag Printing Machine

650,000 Per Piece

Woven Sacks Bag Printing Machine

Get Price Quote

With the constant support of our expert crew of professionals, we are fulfilling the varied requirements of clients by offering optimum quality Woven Sacks Flexographic Printing Machine. This machine is used for printing various types of HDPE / PP woven sacks bags and sheet. Our offered machine is manufactured by our trained professionals using supreme grade components and cutting-edge techniques in adherence to set industry standard. HDPE / PP Woven Sacks Raffia Bags Machinery Bag Printing Machine Print Speed Max Bag Print Speed upto 3000 / Bags / Hour Features Compact size Unmatched quality Low maintenance Areas of Application Prints on various types of (HDPE / PP) Woven Sacks Bags/Sheet.

Flexographic Printing Machine 6 Colors for HDPE Woven Sack Bags

Get Price Quote

Our Company Palm Paper Machines manufactures a wide range of Colour Printing Machines, including Flexographic Printing Machine 6 Colours for HDPE Bags. Being a well-known manufacturer of Printing Machines, we are always strived to bring forth only the supreme quality Printing Machines’ range for you. Our quality range includes ‘6 Colours Flexographic Printing Machine for HDPE Woven Sack Bags’. It is one of the major Printing Machines used in the Printing Industry. Our manufacturing crew is enriched with expertise thus able to provide you a fine grade Flexographic Printing Machines with the help of our high tech machinery. Avail your Printing Industry with our quality and cost friendly Flexographic Printing Machine 6 Colours for HDPE Woven Sack Bags. Some of the key features of our Machines are listed below:● Easy to Operate● Low maintenance● Unmatched Performance● Customized Design● Budget-friendly

Woven Bag Printing Machine

Get Price Quote

The first benefit of of owning such an offset printing machine is the efficiency as it is designed for quick printing while still maintaining quality on both short and long run jobs. The cost per print is the minimum in a non-woven bag printing machine as compared to other printing machinery. Such printing machines are capable of performing half tone jobs, print pictures or images, print screen and background jobs all while maintaining the print quality even with high levels of production. One of the biggest advantages of owning a non-woven bag printing machine is the use of non-woven fabric which is extremely nature friendly. Every company wants to generate good will by supporting causes such as protection of the environment to appeal to various stake holders. For this purpose, non-woven bags comprising of 100% polypropylene filaments are ideal as they are recyclable, they decompose naturally and incineration does not produce any poisonous pollutants. The fabric is also 100% flexible, waterproof, stain-resistant, breathable and highly durable.

Woven Bag Printing Machine

Get Price Quote

Woven bag printing machine This machine will be attached in paper Bag Machine for online Printing. This machine is available in various specifications and can be customized.

Woven Bag Printing Machine

Get Price Quote

in the small size of commercial printing market, flexibility and full service play are becoming increasingly decisive factors. Your customers demand a variety of products that meet their unique needs but are also affordable. Minimum change over time to one job to another and easy to operate is becoming more and more necessary in order to remain competitive. salient features : weight of stock : 30 to 300 gsm paper thickness. machine available with d.c. Drive. water bottle. automatic wash up device save time & labour. chain delivery. multipurpose use for a aluminum plate and polymaster. easy mobility-munted on wheels and with jack-system. all setting adjusted through single handle-inking, damping, & impression. centralized oil lubrication system. oil tray. one man operate the machine easily. rigid construction and vibration free working. * speed range 1500 to 7000 i.p.h. Depending upon kind & condition of stock, thickness, type of ink used, weather, desired printing quality and other operating condition. * illusrations and specification are not binding and are subject to change without notice due to our continuous r & d of improvements / modifictions.

Woven Bag Printing Machine

33,000 Per Piece

1 Piece (MOQ)

WOVEN BAGS PRINTING PLATE MAKING MACHINE (18 X 25)

354,000 Per PERUNIT

All stainless steel. Exposing+drying+washout+treatment. 4 in one design very compact. Simple operation, best plate result

Woven Bag Printing Making Machine

Get Price Quote

DESCRIPTION : This machine is suitable for printing such packing materials as polyethylene, polypropylene plastic bag, glass paper and roll paper, etc. And it is a kind of ideal printing equipment for producing paper packing bag for food, supermarket handbag, vest bag and clothes bag, etc. Characteristics: 1. Easy operation, flexible starting, accurate colour register. 2. The meter counter can set printing quantity according to the requirements. Stop the machine automatically at the set quantity or when the material is cut off. 3. Lift and lower the printing plate cylinder manually, it will automatically stir the printing ink after lifting. 4. The printing ink is spread by the knurled cylinder with even ink colour. 5. Reliable drying system coordinated with high-speed rotation, it will automatically break circuit when the machine stops. 6. 3600 continuous and adjustable longitudinal register device. 7. The imported frequency control of motor speed adapts to different printing speeds. 8. There are inching/stopping buttons on the plate roller base and material rolling rack so as to make it easy operate the machine when the plate is installed.

Woven Bag Printing Machine

Get Price Quote

Woven Bag Printing Machine, Timber Runners, Shelf Bracket

Woven Bags Printing Machine

Get Price Quote

Woven Bags Printing Machine, Circular Weaving Machine, Nylon Gears

PP Woven Bag Flexographic Printing Machine

Get Price Quote

PP Woven Bag Flexographic Printing Machine, Side Sealing Cutting Machine

PP Woven Bag Printing Machine

Get Price Quote

Compact and sturdy construction Streamlined design for maximum speed Easy to maintain and economical No bush bearings, the machine is entirely based on ball bearings Pressure release device avoides unnecessary tinting of conveyor belts Strict quality controls Efficient after sales service

Woven Bag Printing Machine

Get Price Quote

Woven Bag Printing Machine