Zero Discharge System

20,000 Per Piece

5 Piece(s) (MOQ)

We are amidst the dependable Manufacturers, Exporters and Suppliers of the Zero Discharge System. The Zero Discharge System evaporates water from Pretreated Effluent in almost the same way as thermal evaporators, employing the principle of diffusion at normal temperature. To recapitulate the basic aspects of the novel design : Braj Projects Pvt.Ltd. design basically differs from conventional evaporators in the underlying principle; the former uses heat to evaporate water, whereas the later (Braj Projects Pvt.Ltd.'s design) employs the natural phenomenon of diffusion of water which does not require heat. The natural process of diffusion is as such slow, but can be greatly enhanced by, large inter facial area between air and water, turbulence, finer particle size of water and large air to water ratio. It has been proven scientifically in the highly reputed universities and renowned institutions in the West that at sub-micron size of the water particles in the normal atmosphere, the natural process of evaporation, called diffusional evaporation, ensures that it is completely vaporizes before it hits the ground, if released at sufficient height. In order to utilize this well-proven principle for practical and effective evaporation of effluent into water in the atmosphere, the effluent has to be adequately stripped off all its dissolved organic and inorganic contents beforehand, besides removal of turbidity, suspended solids etc. This process of natural evaporation would be dependent on the atmospheric conditions like humidity, wind speed, temperature etc and therefore should be harnessed and designed for the adverse combinations of governing parameters so that at all other time higher evaporation would occur. Braj Projects Pvt.Ltd. does not claim that it has Invented Natural Evaporation By Diffusion, but it does claim that it has harnessed this principle for practical, effective evaporation of effluent into water by perhaps more user-friendly method suitable for the Indian conditions With above background, it becomes clear that the effluent has to be properly pretreated before it is pumped into Braj Projects Pvt.Ltd.'s ZDS involving; equalization, pH control, removal of volatile organics, removal of suspended solids and turbidity, and lastly adequate removal of dissolved impurities. There are basically two types of dissolved impurities in the effluent, organic and inorganic, manifesting themselves as COD, BOD,TOC, etc. and TDS. Firstly, the effluent has to be passed through a packed bed of activated carbon, granular form, with app surface area about 80-100sq meter per gram. It is well known that activated carbon of good quality possesses extremely good adsorptive for most of the organic impurities present in the textile effluents. Therefore, after passage thru carbon bed ,most of the dissolved organics of the effluent would be removed, with optimum contact time and sufficient depth of the bed, say,.5m to 1.0meter and dia of about 0.5 to 0.75m.The carbon bed as usual would have distributors, supporting plate, mild steel shell, inlet and outlet and so on. After removal of organics in the carbon bed of adequate quantity, the effluent is passed through a mixed bed of anionic and cationic resins which are well known to remove inorganic salts from the effluent by the ion exchange process. This would be also made from mild steel shell lined with epoxy to withstand corrosion by the effluent. It would be a packed bed with usual connections like inlet, outlet, distributor etc. The anionic and cationic resins would be in the form of spherical particles packed to sufficient depth and adequate residence time. Both the carbon granules and resins are available in India and have been used in the industry for effluent/water treatment with a high degree of success over the last several decades. Their designs have been standardized in our country. The Overall Picture of Our ZDS Is As Follows Equalization VOC removal by vigorous aeration (optional in the textile effluents) pH control Removal of suspended and turbid particles in a multimedia filter Removal of dissolved organics by the activated granular carbon bed Removal of highly concentrated portion of waste water as recycled stream in effluent storage tank or sludge drying beds Removal of dissolved inorganic(TDS) in a packed bed of ion exchange resins, anionic and cationic both, and then pumping the so pretreated effluent into our ZDS along with compressed air through diffuser modules mounted at 50-60 feet elevation. Typical Characteristics Of The Equalized Textile Effluent pH : 6.5 -8.5 S S : 150-400ppm C O D : 800-3000ppm B O D : 200-450ppm Color : Moderate Oil and Grease : 5-30 ppm Ammoniacal Nitrogen : 50-150 ppm TDS : 5000-15000 ppm Toxicity : Not detected Typical Characteristics of the Pretreated Effluent before Zero Discharge System pH : 6.5 -7.5 S S : 10-500 ppm COD : 70-50,000 ppm BOD : 20-3000 ppm Color : Almost colorless Oil &Grease : 2-100 ppm TDS : 100-2, 00,000 ppm The packed beds of activated carbon and ion exchange resins are cylindrical, vertical columns with valves, pressure gauges, drains, level indicators, opening lids and man holes for cleaning and are self -supporting structures of about 2-3 feet diameter and 4-6 feet cylindrical heights, made from mild steel of about 4-6 mm plate and coated with epoxy paint. The present study on a pilot plant at Braj Projects Pvt.Ltd. over two years and exhaustive study of the commercial plant at a local chemical industry over the last 1.5 years have shown that there are no adverse effects of any kind either on the local climate or human beings or plantations in the vicinity of the ZDS plant as well as in the long ranges by the emissions from the ZDS. This is on the expected line technically also, because what is being discharged from the ZDS is water vapor well mixed with large amount of air and that too at highly elevated level of 50-60 feet from the ground. If we compare this with the discharges of the greenhouse gases from the boilers, driers, thermic fluid heaters and even multiple effect evaporators already approved by the regulatory authorities emitting vapors without mixing with air or the much -touted incinerators' gaseous emissions comprising carbon dioxide, carbon monoxide, heat and toxic substances as byproducts of combustion of the fossil fuels used for generation of heat/steam. This method of zero discharge is superior and much more eco-friendly on equivalent basis. Needless to mention, that like all other novel technologies emerging in the horizon in the global environmental scenario, the ZDS is also not cent per cent perfect, it does have a few limitations, however, if the industry has to opt for a zero discharge system that is very near to the sustainable, practical, cost effective and eco-friendly method of ensuring no liquid discharge. Braj Projects Pvt.Ltd.'s ZDS provides and tries to fill in the vacuum amongst the plethora of pseudo- zero discharge systems available in the Indian market. During the developmental process of the Zero Discharge System Braj Projects Pvt.Ltd. learnt that in one of the highly developed countries, such systems of very large capacities at industrial scale have been operating successfully for over 10-15 years. Now Braj Projects Pvt.Ltd. also has gone up to a full-fledged commercial plant employing this novel concept and it is of the opinion, based on exhaustive trials so far, that the system is techno-economically viable and sustainable remedy to the Zero Discharge compliance problem of the industry has ultimately arrived on the Indian horizon. Outcome of the Zero Discharge system Treated trade effluent disposal problem of a land locked industry will be solved on a sustainable way. Compliance of Zero Discharge norm will be achieved by the industry. Occasional underground pollution of the water strata will be solved. Price Range : Ranging from Rs. 5 Lakhs to 2 Crore

Zero Liquid Waste Discharge System

Get Price Quote

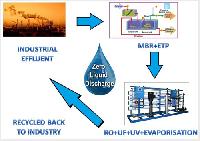

Zero Liquid Discharge System for all kind of effluent, A ZLD system is a treatment process which is used to remove all the liquid waste from a system. The goal of ZLD water treatment is to reduce wastewater economically and produce potable water that is fit for normal use. Zero liquid discharge system is an advanced treatment method that comprises ultrafiltration, reverse osmosis, evaporation and fractional electro deionization. And we are a well-known supplier of ZLD systems.

Best Deals from Zero Liquid Discharge Systems

zero liquid discharge system

Get Price Quote

1 Set (MOQ)

Zero Liquid Discharge Plant

55,000 Per Unit

1 Unit (MOQ)

ZLD System for Chemical Industries

565,000 Per piece

1 Set (MOQ)

zero liquid discharge system

Get Price Quote

Zero Liquid Discharge System to Maximize Wastewater Reuse and Eliminate Liquid Waste – Pollucon Engineering, a Environmental Engineering services company, Manufacturing and installation of water treatment plant incorporating ZLD (Zero Liquid Discharge) systems for the Different Categories of factory.

Zero Liquid Discharge Plant

Get Price Quote

1 Piece (MOQ)

Zero Liquid Discharge Plant

Get Price Quote

Zero liquid discharge (ZLD) is an engineering approach towater treatment where all water is recovered and contaminants are reduced to solid waste. While many water treatment processes attempt to maximize recovery of freshwater and minimize waste, ZLD is the most demanding target since the cost and challenges of recovery increase as the wastewater gets more concentrated. Salinity, scaling compounds, and organics all increase in concentration, which adds costs associated with managing these increases. ZLD is achieved by stringing together water treatment technology that can treat wastewater as the contaminants are concentrated.

Liquid Overfeed System

Get Price Quote

We offer Liquid Overfeed System in different sizes as per the requirement in Ammonia Plant. Liquid Overfeed Systems (re-circulation system) are those in which excess liquid is forced, mechanically or by gas pressure, through organized-flow evaporators, separated from the vapor, and returned to the evaporators. This ensures no oil in the evaporators and no liquid slugs in the compressor leading to high saving in power and maintenance. We present carefully designed Liquid Overfeed System in domestic as well as international markets. Positioned as one of the leading Liquid Overfeed System Suppliers, we offer them at reasonable prices by us. Advantages Even refrigerant distribution Protection of compressors Hot gas defrosting No effects of fluctuating ambient and condensing conditions Zero pressure drops in the evaporators / overfeed lines Ease of operation Low maintenance Materials Used Steel Tube Pipe Channel Angle Seamless pipe Shell Laval gauge Liquid pump Valve flow control Attributes Compact design Power saver Fully automatic operation Truck size plant Easy transportation Applications Cold Storage Ammonia refrigeration plant

Zero Liquid Discharge Plant

Get Price Quote

Our products are the preferred choice of many, as they are grade assured and as per international quality management systems. The packaging of our products is done using high-grade packaging material. Moreover, we are assisted with advanced machines and packaging experts for safe packaging of the products. Our zero liquid discharge plant is designed for easy installation, simple operation, low maintenance and long service life.

zero liquid discharge systems

Get Price Quote

We expertise in providing Zero Liquid Discharge Solution to our customers thus abiding by the stricting pollution norms and contributing to environment. We first try to limit the source of effluent and then work upon its recycling .Our well designed ETP on latest MBR based technology provides better quality effluent which gives us an edge over other treatment systems available in the market.

zero liquid discharge system

Get Price Quote

Features: Effective on contaminated water Easy installation Modular construction User friendly operation Long lasting performance

Zero Liquid Discharge Plant

150,000 - 2,000,000 Per Piece

1 Piece (MOQ)

A Zero Liquid Discharge (ZLD) plant is a wastewater treatment system designed to eliminate all liquid waste streams that are typically discharged into the environment or sewer system. In a ZLD plant, wastewater is treated using a combination of physical, chemical, and biological processes to remove pollutants and contaminants. The treated water is then reused, while the remaining solid waste and brine are either disposed of or further treated to recover valuable resources.

zero liquid discharge system

Get Price Quote

zero liquid discharge system

2,850,000 Per Piece

"To attain the maximum satisfaction of our clients, we are engaged in offering supreme quality range of Zero Liquid Discharge System. This product is extensively used as an excellent Water treatment at various industries. Furthermore, clients can avail this product at market leading prices. Features Easy to operate Eliminate liquid waste Better efficiency

Zero Liquid Discharge Plant

8,000,000 Per Piece

Liquid Overfeed System

Get Price Quote

Our Liquid Overfeed System is acclaimed for its high efficiency. Having association with the leading names enable us to deliver high quality products to our worthy clientele. In addition to this, we procure the basic material from the trusted places only. We have gained complete customers satisfaction as we make maintain proper schedules for the delivery of the consignments

Zero Liquid Discharge Plant

Get Price Quote

1 Piece (MOQ)

The genesis of Antichem Equipments can be traced to 2005. when a group of technocrats with years of experience in diverse fields decided to pool their combined talent and create an engineering company that would be a projection of their personality and achieves their goals. Antichem Equipments is the outcome. commenced Reg. Office at Salem, District, Tamil Nadu. we having a factory Facility for Fabrication at Perundurai. providing technical consultancy to diverse industries while commencing the manufacture of a range of evaporators, distillation columns, and dryers. Today we have experienced core staff with numerous contractors and sub-contractors. In a short time, we established ourselves as the leading manufacturer of Evaporator, ATFD, Distillation Column, Heat Exchanger, etc., in TN. Our approach is based on knowledge, concept, design, planning, and execution, especially when it came to specialized Falling Film Forced Evaporator and Thin Film Evaporation technologies. Our competencies covered the entire gamut of Zero Liquid Discharge systems, Multi-Effect Evaporator, and ATFD technologies allowing us to design and deliver solutions to meet client needs. ANTICHEM EQUIPMENTS Leads under superior engineering design capabilities, manufacturing excellence, and a project-based approach for commitment to delivery with high performance for total evaporation solutions customized to client’s requirement. Our Product Range Falling Film Evaporator Plant Forced Circulation Evaporator Plant Rising Film Evaporator Plant ATFD Product Concentration Plant Stripper Column Distillation Plant

zero liquid discharge system

5,000,000 - 20,000,000 Per Per Number of Plant

1 No. of plant (MOQ)

Zero Liquid Discharge Plant

300,000 Per Piece

1 Piece(s) (MOQ)

Zero Discharge System

Get Price Quote

Zero liquid discharge consists of industrial wastewater treatment processes developed to totally wipe out all liquid discharge from the industrial facility.a zero liquid discharge is a procedure that is beneficial to industrial and municipal governing bodies as well as the environment because it saves money and no liquid effluent, are discharged from the facility.

zero liquid discharge systems

100,000 Per Set

1 Set(s) (MOQ)

Zero Liquid Discharge (ZLD) represents the ultimate cutting-edge treatment system for the total elimination of wastewater effluent into neighboring waterways. The ZLD System removes dissolved solids from the wastewater and returns distilled water to the process (source)

AKVAZEN

Get Price Quote

1 Piece(s) (MOQ)

Biznustek�s � Innovative Zero Liquid Discharge System AKVAZEN� treats the process water to obtain clear water which can be re-used in the Industrial Process, thus lowering the cost of fresh water replenishment. The residue obtained after treatment is concentrated which minimises the cost of disposal.

Zero Liquid Discharge Plants

1,500,000 - 5,000,000 Per Nos

1 Number (MOQ)

zero liquid discharge systems

1,000,000 - 5,000,000 Per Piece

zero liquid discharge system

500,000 Per Piece

zero liquid discharge systems

1,500,000 - 2,500,000 Per Piece

zero liquid discharge system

4,000,000 Per Piece

Zero Liquid Discharge Plant

1,000,000 Per Piece

Zero Discharge System

Get Price Quote