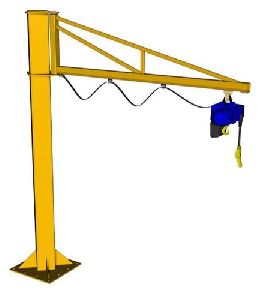

Jib Crane

Get Price Quote

Jib Crane

Get Price Quote

01 Piece(s) (MOQ)

We have in store for our clients a qualitative range of Jib Cranes. These products are manufactured under the close supervision of experienced and qualified professionals. All our products are widely used for heavy equipment loading, material loading and unloading and light assembling work. Post-procurement, these products are stringently inspected by experienced quality controllers on certain parameters in order to rule out every possibility of defect

Looking for Jib Crane Services Providers

Pillar Mounted Jib Crane

125,000 Per Piece

1 Piece (MOQ)

Jib Cranes

100,000 Per Set

1 Piece(s) (MOQ)

JIB Cranes are suitably used for workstation jobs and as maintenance cranes. These are mainly utilized in railway, automobile, pharma, tool rooms, machine shop departments to part the work-cycle and loads of E.O.T Cranes. The lifting capacity ranges from 0.5 Ton to 15 Tons. Application sector gives span range from 2-15 meters and lifts up to 10 meters. Depending on the supports and space availability Jib Cranes are categorized as follows: a FLOOR MOUNTED 1. Free Standing Jib Crane 2. Double Boom Jib Crane 3. Mast Jib Crane 4. Free Standing Workstation Jib Crane 5. Free Standing Articulating Jib Crane 6. Portable Jib Crane 7. Foundation less Jib Crane b WALL OR COLUMN MOUNTED 1. Wall Cantilever Jib Crane 2. Wall Bracket Jib Crane 3. Wall Cantilever Work Station Jib Crane 4. Wall Mounted Articulating Jib Crane 5. Ceiling Mounted Articulating Jib Crane 6. Wall Travelling Jib Crane RBS Cranes has wide experience of custom made Jib Cranes, which we can supply in very short time of period and rare economical prices.

Jib Crane

1,200,000 Per Piece

1 piece (MOQ)

We have made our mark as the distinguished Manufacturer, Exporter and Supplier of Jib Crane from Punjab, India. The Jib Crane is fabricated by skilled professionals who adhere to the norms set by industrial regulatory bodies. Owing to our efficient logistics network, customers can rely on us for delivering small or bulk orders of Jib Crane within the allocated time. More about Jib Crane :Our product range, Pillars & Wall Mounted Jib Cranes is directly available at workplace where a worker can lift, quickly transport & precisely deposit all kinds of work pieces. Usually these cranes are used where other materials handling equipments can’t be used for any structural reasons, These are completely free standing workplace cranes & can be used for outdoor storage yards & loading ramps.Manually handling and combining or moving relatively light loads is often not only time-consuming, but also an ergonomic burden for employees. In this way, setting up and idle times can be significantly reduced and periods of waiting for workshop cranes to become available can be completely eliminated. Further strengths of our pillar and wall-mounted slewing jibs include: Light and fast load handling Ease of operation and high operating safety and reliability Load capacities up to 5,000 kg. Simple installation using fittings included in the system. Available up to 5mtrs of swing arm. Up to 360 degrees of swings Manuals & Motorized Swings.

Jib Crane

201,000 Per Piece

1 Piece (MOQ)

Jib Crane

4,500,000 Per Piece

1 Piece (MOQ)

A hoist, wire ropes, chains, and sheaves are all parts of a crane. These cranes are used in many different ways in our daily lives. Industries set their preferences for various crane models based on capacity. Industries take extra effort to ensure a good decision by examining manufacturer specs and comparative advantages. Jib cranes typically have fixed jibs, however occasionally they may also have movements. The fundamental design of a Jib Crane is one of its key features. To ensure safety and effectiveness, a high specification constructed in conjunction with top quality manufacturing is crucial. Pipe and rolled steel pieces must be used in the fabrication. Another element to be on the lookout for is rigid columns. This stiffness is provided by broad base plates and M.S. gusset plates. Jim arm, which is made from a large section beam and a triangular truss structure, reduces deflection to acceptable levels One has to seek for double roller self-aligned bearings with thrust and roller bearings in them to handle the vertical and horizontal stress in addition to the radial thrust. It's necessary to consider swivelling. Jib Crane enables simple swivelling with the aid of the chain at the jib arm's end and/or manual cranking. Another option is to go with an electrically powered swivel integrated system. Brass swing springs that are completely insulated and equipped with pantograph current collectors guarantee a full 360-degree rotation

Pillar Mounted Jib Crane

Get Price Quote

1 Piece (MOQ)

Jib Cranes

Get Price Quote

Features Tough and tensile Easy to use Low maintenance Greater load capacity Long lasting

Jib Cranes

Get Price Quote

Our exclusive Horizontal Jib Cranes are the outcome of our employment of cutting-edge technology. Owing to the same, our Heavy Duty Jib Cranes conform to IS 807 as well as IS 3177 which ensure optimum quality of the product. These Jib Cranes occupy less space and are easy to install. At the same time, it can be mounted on any structure. The entire range is available at the most competitive prices. Today, we are counted as the leading Vertical Jib Cranes Manufacturer in the market. Features : Conforms to IS 807 and 3177 Mast Fabricated from Pipe/Rolled Steel Sections M. S. Gusset plates/thick base plate for rigidity Double roller self aligned type bearings with thrust & roller bearings for horizontal & vertical loadings as well as radial thrust Positive full 360 degree rotation duly insulated brass swing springs with pantograph current collectors provided Base plate readily drilled to take six/eight holding down bolts

Jib Crane

4,000,000 Per Piece

1 Piece (MOQ)

Jib Crane

Get Price Quote

As a trusted Jib Crane Manufacturer and Supplier from India, we offer a powerful material handling equipment for various industries. Featuring a mast constructed from pipes or steel rolled sections, the Jib Cranes have cover plates or fabricated girders to offer a powerful performance. With mild steel Gusset plate/thick base plate fabrication, the Jib Cranes have enhanced rigidity in their structure. Features and Specifications : Construction and Design : as per I.S. 807 and I.S. 3177 Mast : Pipe or Rolled Steel Sections are used in construction Plates : For additional column rigidity, the Mild Steel Gusset plate or thick base plates are used, where the base plates take 6-8 holding down bolts through drilling. Jib Arm : Construction is done in the following manner to reduce deflection LUJC-I- heavy section I beam LUJC-2 and LUJC-3 - triangular truss constructions Bearings : For vertical, horizontal and radial loadings, the self-aligned bearings are used that include types for thrust and double roller types Swiveling : This is done by chain located at the Jib Arm�s end or manually by cranking with hands. In SMJC-3 jib crane swiveling can be done by electrical operation mechanism (on request). If a full and positive 360° rotation is needed, then current collectors of pantograph type are provided that are constructed using brass swing springs with insulation.

Pillar Mounted Jib Crane

150,000 Per Piece

1 Set (MOQ)

Jib Cranes

250,000 - 900,000 Per piece

1 piece (MOQ)

Jib Crane

Get Price Quote

Backed by an industrious team, we are able to offer precision make Jib Crane in the industry. Suitable to be used for all types of mineral mining area, the Jib Crane is widely demanded by Mining industry. The Jib Crane we offer is known for the high performance and sturdy construction. The clients can avail the Jib Crane from us in various specifications at highly affordable price.

Jib Crane

450,000 - 1,000,000 Per piece

1 Piece (MOQ)

Jib Crane

75,000 - 375,000 Per piece

1 Piece (MOQ)

Jib Cranes

Get Price Quote

We are a prominent Jib Cranes Manufacturer recognized as an Exporter and Supplier in India and around the world. Designing and production of the Jib Cranes is done to give different types as per the capacity. Made using heavy-duty components, the Jib Cranes are made to have a long functional life and offer reliable performance in handling material safely for a long time. Construction MastCarbon steel pipe of various sectionsThickness : As per loading conditions, boom length, height etc.Armsection or as per specificationsAlso made from Zero friction rail to suit ergonomic handling systemsVertical ArmStandard sections or built up sectionsAs per capacity and sizes of craneElementMade up of robust bearing assemblyLess maintenance requiredGuide Ring360o rotation type jib craneVertical arm rotates over thisRequires regular cleaning and greasingGuide Wheel AssemblyConnected to the vertical arm that rotates on guide ringNeeds regular cleaning and greasingSpanThe arm length of craneHook HeightWhen it is in IOD position, it stands for maximum height of hook hoistOverall HeightMaximum crane height over which no crane part is extendedBaseM.S. Plate, with size as per crane size and capacityFoundation bolts or Chemical Anchoring can be providedMechanical StoppersTo restrict arm rotation to operating area Installation (Plumbing Mast) Usually installation is done using chemical anchors bolts and by foundation bolts in heavy-duty cranesDrop plumb line from top of mast, using fixture or equivalentAt point 50 mm below the top mast plate, set plumb line a distance of 100 mm from the surface of the mast pipeAt point "Y", 1500 mm below point "X" (approximately where rollers will contact mast pipe), the distance between plumb line and the surface of the mast pipe should also be 100 mmWhen mast is plumb and grout (FS300l) has cured; fully tighten the anchor bolt hardwareVerify mast is plumb or notTo prevents doom drifting Mast should be plumb Salient Features Standard Variable Frequency Drive (VFD)VFD ideal for single or multiple speed requirementsExcellent load control is offered by VFDPositioning from slowest to maximum speed is easily possibleUp to 25 times smoother than ballast resistor controlsProduces very less heatAccurate starting and stoppingEasily adjustable speed controlControl panel with simple keypad for adjustingAcceleration rateDeceleration rateRotation speedLow cost of maintenanceNo need for magnetic reversing contractorsReduces wearable componentsPanel wiring dig and VFD Manual is provided with crane Maintenance Instructions Periodicity greasing of main elements in between 6 to 12 months as per operational frequencyChecking of foundation bolt fittings should be done at fixed intervals to avoid arm rotation imbalanceGreasing of Guide Ring should be done on a monthly basis or earlierLoosening of Gear meter bolts must be checked to see gear and pinion alignment is proper or not Demanded by Steel PlantsConstruction industryChemical industryRefineriesDefense sectorMining industryNuclear power plants

Jib Cranes

Get Price Quote

1 piece (MOQ)

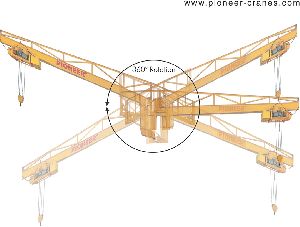

Jib Cranes

Get Price Quote

Pioneer Cranes bring forth an extensive range of JIB Cranes that is manufactured as per international quality standards. These cranes can be easily mounted to various applications including facility floors, walls, foundations, columns, pillars etc. Playing an active role in lifting material, these cranes are known for their unmatched quality and long service life.Jib cranes are highly adaptable, and fit well to various workshops and industries. They are a cost-effective method of handling construction materials of up to 10000 kg. Advantages of Jib Cranes Load Bearing Capasity upto 10000 kg. Easy Installation and Relocation, saving on both production downtime and the cost of installing or moving the crane. Self supporting, mounted on wall or column provides flawless support to it. Available in Rotation Angle of 180, 270 and 360 degrees.