Vibratory Shakeout

Salient Features Vibratory Shake-out Machines are specialty designed to knock ojf the sand from the Mounding box. The construction is simple but rigid and dependable to Modern Engineering Practice. The Top Frames is integral with the heavy duty chute, which in turn is made integral with the heavy duty Eccentric shaft Assembly. The base frame is specially designed to withstand heavy shocks and over loads and which is provided with proper spring rests. The springs are designed in such a way that it will transmit very less vibration eject to the base frame. The Grid in which the top frame is bolted vibrates at great efficiency, which is constant over the entire area, and it will give the maximum achievable capacity. The Eccentric weights are made in such a way that it can be adjusted to meet the requirements. The bearings are protected from dust by housing and covers. Oil seals are provided to avoid sand interruption. Knockout can be supplied with High Efficiency Vibro Motors. TECHNICAL DATA

...more

Vibratory Feeder

Salient Features Vibratory Feeder is specially designed to feed the sand from one place to another The Top frame is made of Flats and Bars which is integral with the heavy-duty eccentric shaft assembly. The base frame is specially designed to withstand heavy shots and overload. The Upper and Bottom Frames are supported on springs, which is designed in such a way that it will Transmit very less vibration effect to the base frame. The Trough vibrates with higher efficiency, which is constant over the entire area, which gives the maximum achievable capacity The Eccentric shaft runs on heavy duty double row self aligned spherical roller bearings, which is protected from dust housing and covers. Oil tank is provided at the end of the shaft assembly to give the proper lubrication to the gears. The Total Trough will vibrate with the help of the springs mounted with the base frame and Trough, due to the vibration produced the sand particle will move from its place and it will discharge through the discharge open.

...more

uniflow conveyors

The Sand preparation is one of the important activity in the Foundry. In this, the sand is prepared for the manufacture of the Mould. The return sand from the return sand hopper is discharged through an uniform arrangement fed into the feeder belt conveyor for charging the sand into the two way chute. The New Sand from the hopper is conveyed to the Intensive Mixer through the two way chute by a vibro feeder kept below the New sand hopper discharge portion. After receiving the return sand, new sand and additives as a batch through Two way chute, the batch hopper will deliver the sand into the mixer shell. At the time of mixing the water will be automatically added into the shell and the mixing will be made uniform. After completion of the mixing process, the sand is delivered and fall into the surge hopper. From Surge hopper, the prepared sand is conveyed to the Moulding sand hoppers kept above the Moulding machines through the distribution belt conveyor.The surge hopper allows only uniform controlled sand to travel on the distribution belt conveyor. At distribution belt conveyor, Straight ploughs are placed for diverting the prepared sand into the Moulding Sand hopper.

...more

tumblast machine

The SSEC Tumblast cleaning machine offers favourable, convincing solutions for blast cleaning of small and medium size work pieces, in batch quantities. the TB series will accommodate batch weights of 180 kg to 1360 kg. The applications of these machines are especially variable :Blast Cleaning of iron castings, precision castings, and die castings. Descaling forgings or heat-treated work pieces. Shot peening for surface compaction. Deburring of metalic (e.g. stampings) and non-metalic work pieces. Surface finishing. Tumblast cleaning machines have been successful over several years and in thousands of applications, often in multishift operation. The TB series have proved to be economical for low production and optimum blast cleaning. The TB series offers the following advantages :Attractive Price / Value ration Rugged, Compact design Ease of operation High blast cleaning performance Quick and easy replacement wear parts DESIGN AND SEQUENCE OF OPERATIONSDepending on the weight, size volume, and flow rate of the castings to be cleaned, the machine can be loaded in a manual, mechanical, or automatic mode. The work pieces are then tumbled inside the blast cleaning chamber consisting of a continuous troughing rubber belt conveyor and lateral discs of highly wear resistant material. Specially designed rubber belt conveyor assure gentle tumbling and full exposure of all surfaces. Burrs, scale, or sand drops passes through the perforations to the bucket elevator and the separator. After passing through the separator for removal of impurities, the abrasive returns to the storage hopper. Mechanical loaders are used for the machine on special request. The Shot blast machines can receive the parts to be cleaned directly or using separate transport bins of the standard sizes. SSEC blast wheels are renowned for high capacity and maximum energy efficiency. These blast wheels come in various power ratings, giving a high degree of flexibility. With modifications it is possible to reverse the blast wheel rotation thus allowing a greater range of applications. The amount of abrasive can also be adjusted. The abrasive is mechanically pre-accelerated and delivered to the blast wheel in a continuous stream, this ensures optimal utilisation of the power from the drive motors. High wear resistant material ensures maximum service life of the blast wheel. Unique features allow for rapid and simple replacement of wear parts.

...more

Swing Frame Grinder

Salient Features Swing frame grinders are used to grind the heavy weight castings that a man cannot be handled manually. The Swing frame grinder is fabricated from MS Section can be hanged anywhere and can be used. The bearings used are heavy duty antifriction ball bearings. The Grinding wheel is protected with the covers and the 'V' Belts with belt guards. At the front end of the grinder; two handles are welded for handling the grinders while grinding. The rear end of the grinder is mounted with heavy duty electrical motor. TECHNICAL DATA

...more

SSEC MIXING BLADE

Mixing Blade mounted on output shaft of the bearing housing and coupled with the gearbox for smooth running. Periodical coating on blade surface with hard facing electrodes or with tungsten carbide brazing yields longer life. The curvature of blades ensures perfect mixing and makes it possible to discharge the entire mixed sand and keep the surface clean to receive the next quantum.

...more

SSEC BLENDING BLADES

Blending Blade rotate at high speed and in opposite direction to mixing blades. Additives are perfectly mixed and sand particles are evenly coated all around.

...more

Shots separation

The Shots separation is done in two stages. First stage by means of magnetic drum and the second stage by means of Air distribution system. The Magnetic drum separates the shots and dust in two levels. In the first level, the shots are evenly distributed with the heh of a screw feeding system by which most of the shots are separated and fed to the Air distribution system. The shots which are not picked up by the first level of the Magnetic drum goes to the second level for separation the shots are directed to the machine and the dust is collected separately.

...more

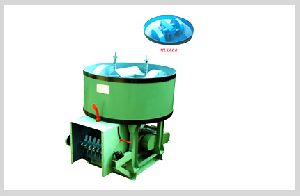

Sand Mix Mullar

SSEC Heavy duty sand Mixer / Muller are of sturdy construction and easy to maintain. The adaptation of a successful procedure to modern requirement of sand preparation at increased rotary speed and adjustable pressure. The possibility of adjustment of the Muller pressure creates the best conditions for all types of sand. Muller pan is protected with wear resisting replaceable bottom plates and the sidewalls within the zone of the scrapers. Two scrapers are so designed that one brings the sand under the Muller and the other takes it out. The scrapers are brazed with tungsten carbide tips. Crib is fabricated from MS Plates are reinforced at the top and bottom to prevent any disturbance while the machine is working. The crib is bolted to the pan base and is detachable for maintenance purpose. Best quality and tested raw materials are used and hence long life is ensured even at high working rate. Special housing assembly ensures no leakage of sand and water from the pan. OPTIONALS Pneumatic door Hood Skip Charger Built in Aerator Anti abrasive non sticking material liner Heavy duty scrapers for Flyash mixing.

...more

sand drier

Salient Features Unique Design of in-built Sand Feed Technology. High Efficient double shell design rotary sand drier which ensures uniform sand drying. Wheels are mounted on the base frame in such a way that while rotation there will be no slippage or improper transmission of power from the gear unit to the shaft. One end of the shell is mounted in the combustion chamber and it is connected with oil tubes and blower pipelines. The inside of the shell is welded with longitudinal flights for ease of travelling and effective drying.

...more

Sand Cooler

Return Sand Temperature, after the vibratory shake out in a mechanized green sand foundry is around ZOOGC. The sand temperature is highest arbacent to the metal surface and lowest away job it. The quantity of heat to be removed depends on the sand to metal ratio and the holding time of metal in the mould. The return sand temperature at the inlet of the cooled after passing through conveyor is around 1 OOOC. Mould of good quality and clean casting surface require well cooled sand,Sand Cooling requires a continuous and uniform flow to achieve the uniform flow and compensate for irregular Sand supply the sieved hot return sand is stored in a surge hopper from there; a belt transports the hot sand to the cooling conveyor which is designed with a perforated bottom plate. Fresh air is blown through the preparation holes and at the same time water is sprayed on to the sand from nozzles located above the conveyor vibrations of the conveyor and turbulence caused by the air blown through ensure that sand water mix well so that The water evaporates and the sand is cooled. The belt, the cooling conveyor and the sand spraying unit are controlled by level indicators located in the surge hopper the plant operates only if the sand in the surge hopper is between the maximum and minimum level.

...more

RETURN SAND IN GREEN SAND FOUNDRY

Return Sand Temperature, after the vibratory shake out in a mechanized green sand foundry is around ZOOGC. The sand temperature is highest arbacent to the metal surface and lowest away job it. The quantity of heat to be removed depends on the sand to metal ratio and the holding time of metal in the mould. The return sand temperature at the inlet of the cooled after passing through conveyor is around 1 OOOC. Mould of good quality and clean casting surface require well cooled sand. Sand Cooling requires a continuous and uniform flow to achieve the uniform flow and compensate for irregular Sand supply the sieved hot return sand is stored in a surge hopper from there; a belt transports the hot sand to the cooling conveyor which is designed with a perforated bottom plate. Fresh air is blown through the preparation holes and at the same time water is sprayed on to the sand from nozzles located above the conveyor vibrations of the conveyor and turbulence caused by the air blown through ensure that sand water mix well so that The water evaporates and the sand is cooled. The belt, the cooling conveyor and the sand spraying unit are controlled by level indicators located in the surge hopper the plant operates only if the sand in the surge hopper is between the maximum and minimum level. Sand Moistening Sand temperature are measured at the entrance of the cooler and in the third stage of the cooler An electronic thermometer controls the amount of water sprayed in several steps. Depending on the values, measured, a variable Number of spraying nozzles is engaged or disengaged. This ensures exact dosage of the water required for cooling and moistening. The nozzle units are engaged automatically in steps depending on the sand temperature. Salient Features Cooling system ensure constant temperature and moisture to the return sand Low maintenance due to absence of moving parts. Quick cooling by double ejfect water and air cooling. Sand movement effected by the fluidization property of sand and vibratory motion Balanced draft system ensures negative pressure above the bed Environment friendly Benefits Substantial reduction in rejection of casting. Saving in conversion cost of rejected castings. substantial Saving in bentonite consumption Excellent surface finish of casting Increased productivity No oolite formation occurs in mulling. Continuous online use of return sand Ease of maintaining permeability and hardness of the mould Saving in man power cost. Standard Models

...more

Reclamation Plant

SAND RECLAMATION PLANTThrough out the most Industrialized countries of the World, increasing environmental concerns and the costs of purchasing quality moulding sand make the recycling or reclamation of the used sand more attractive. To make acceptable moulds, several conditions of recycled sand must be achieved. The sand must be restoted to a condition where The grain size distribution The binder content on the grains The presence of foreign materials and metals. The moisture content. The Temperature all meet certain standards The reclamation system that allow the foundries to recycle upto 95% of the sand. Cutting New Sand addition down to as low as 5% without a loss in Mould quality. The Primary method SSEC uses to achieve these results is Attrition reclamation, that is wearing of binders from the sand grain through mechanical means. When the residual binder level is more the tensile strength of the mould surface finish are all lowered. SSEC Reclamation system removes the binders without damaging the sand grain structure or increasing the dust content in the sand. The main advantage of SSE C Reclamation system is that it produces rebondable sand at the lowest cost of per Ton of any other system achieving similar quality. The Reclamation system consists of Shakeout Lump Breaker Sand Elevator Sand Attrition unit Sand Cooler/ Classfier Dust Collection System Salient Features Shakeout Dis - integrates bigger lumbs by means of vibratory Motors. Shakeout is placed on a robust spring base. Second Stage lump breaker removes bigger particles by means of sieving and attrition. Centrifugal Attrition units remove the sodium silicate by means of mechanical attrition. Cooler Classifier removes fine dusts and solid by means of Fluidisation Technology. On - line and Continuous process Less Man power Less Maintenance and less space occupied Range I Ton/hr to I 0 Ton/hr

...more

Punch Out Machine

Salient Features Punch out Machine are designed for easy knockout of the sand fromthe Mould boxes to the Shakeout Machine. The Punch head is specially designed as per the Customer's Box size. Avoids damages to the boxes. Punch heads cleans the inner surfaces of the boxes during punching itself Hydraulically operated hence smooth operation for punching. Long travel can be given either mechanically or pneumatically. Long travel by Rack and Pinion system hence precise. Punch heads are precisely guided, hence no abnormalities during punching. VFD ensures smooth and perfect positioning for Long travel. The Total system is controlled by a separate control system. Ranges offered:As per Customer's Box size.

...more

Polygonal Sieve

Special Features Polygonal Siever is specially designed to sieve the Moulding sand to get the quality of castings. It consists of Sieve Drum, Main Casing, Receiving Chute, Delivery Portion, Disposal chute and Drive Unit. The Sieve Drum is a fabricated one made of Flats and MMM,Channels. The Sieve Drum resembles the shape of a Hexagonal Pyramid. The Receiving Chute is designed in such a way that the sand. will not chock anywhere in the walls of the chute and it will easily reach the sieving area. By the Rotary movement, the sand is sieved and also the lumps breaking operation also takes place which thereby Improves the recovery of the Return Sand. The Drive unit is through standard motor and a proper Gear unit. By coupling the Motor and Gear Box, the power is transmitted The output shape of the Gear Box is coupled with the shaft, which provides a trouble free transmission

...more

Pneumatic Conveyor

Salient Features Low-velocity Dense-phase Pneumatic Conveying Systems Economical and reliable transfer of almost all bulk materials through pipelines Dust and Spillage free with NO constantly moving parts Extreme Reliability and Low Maintenance Typical Materials are Abrasive, hot, moist and a mixture of dissimilar materials.

...more

Pedestal Grinder

Salient Features Pedestal Grinders are used to grind the cast pieces. At the same time two persons can grind at a time. The main body is fabricated with heavy MS section by that the vibration due to grinding will not be more. The plate’s side of the body is bolted with the frame for easy removal, handling and Inspection purpose. The Motor position can be adjusted up and down to get the belt tensioning.. Belt guard is provided at the top of the frame for safety purpose. The grinding wheels are protected by two separate side covers for safety purpose. There is a passage at the bottom of the cover for the grounded materials to fall on to the ground Pedestal Grinders can be supplied with Integral Dust Collection System TECHNICAL DATA

...more

Overhead Casting Conveyor

OVERHEAD CASTING CONVEYORSSSEC Over head casting conveyors are specially designed for handing high temperature and heavy castings from knockout area to the fettling shop. Over head conveyors can work in dusty atmospheres and operate in temperature of up to 250“ C Also steel structure s are designed to be versatile and can negotiate ups and downs and horizontal bends to suit existing layout and Equipments. High quality Chain wheels are used for casting carrying. Special features High strength forged link rivetless chains Two wheel trolleys with brackets forged out of high strength steel. Sealed wheels to withstand dust and corrosion. Handling of High temperature material to the considerable inclination and length. Low noise level and low power usage. Conveyor is equipped with variable speed drive as an optional. Component pitch can be varied according to the requirement.

...more

Moulding Machine

Engineering at its Best Free floating anvil for shockless jolting to protect your foundation. Precisely guided pin lift with Hydro-pneumatics. Hydro - Pneumatic swing in - swing out. Centralised Forced lubrication on every cycle to ensure longer life of wearing parts. Simple pneumatic controls for easy maintenance. Hand wheel operated squeeze plate adjustment. Short cycle time due to low amplitude, high frequency jolting mechanism to meet stringent conditions of automised moulding line.

...more

Moulding Box

Salient Features Rigid in construction. Provided with additional corrugation. Accurate pin centres with precision Drilling. Hardened Bushes. Ranges ojfered: 400 x 400 mm to 1500 x 1200 mm (Inner size) 75 to 350 mm height

...more

mould accessories

SSEC manufacture cast iron moulding boxes suitable t0 the customers requirements. SSEC also manufacture accessories like mould box bushes, closing pin, machine guide pins. `C ' clamps, match plates, etc., BUSHES Flat Bush Round Bush CLOSING PIN Round Pin Flat Pin Ranges ojfered: 400 x 400 mm to 1500 x 1200 mm (Inner size) 75 to 350 mm height

...more

Monorail Shot Blasting Machine

In the Monorail type Shot Blasting Machine, comes with Manual movement or Motorised movement of hangers into Blasting cabin. The movement of hangers through the machine is achieved by a Transport system moving in intervals continuously. With the advantage of number of hangers, loading and unloading of castings becomes easy and can be carried out while the machine is in operation. The doors are provided with Hydro Pneumatic system, which makes the door to open when the cycle is completed and the hanger movement is ejected by this arrangemement. Until and otherwise the blasting is stopped, the door will not open and after closing of door only blasting starts, which makes safety to the working of the machine. During the blasting cycle, the hangers are placed in two positions, which makes the efficient cleaning of the casting. The cabins are lined with high Manganese rolled plates which will eliminate the rubber avoid damage to the cabin, improves the live of the machine and reduce the maintenance cost.

...more

Monorail CONTROL PANEL

In - house design and manufacture of Shot Blasting control panel is a stand alone system consisting of Motor circuits for blasting units, bucket elevator, hook spinning, Motorised movement of the hangers and I. D Fan etc., These are enclosed in a sheet metal enclosure of highest quality. The operator interface, push button, selector switches, indicators, meters etc., are located ergonomically on the front door of the control panel for , easy operation. Optional features for operator inteiface includes mimic panel having dual colour LED lamps and LCD `il message display unit. The control equence are designed either using hardwired relay logic or state of art Programmable Logic Controller [PLC] depending upon the Application requirement. Chamber of sturdy steel fabrication : Areas directly exposed to shot stream is lined with wear resistant materials, other areas with heavy duty wear resistant rubber. Quick blade Change. Precise setting of shot stream for effective blasting. Dynamically balanced rotors. High rate of shot through put. Impeller wheels : Location and quantity to clean castings in one pass. Uniform Shot Stream. Exclusive wind swing arrangement. Dust extraction by means fabric filter bags arrangements. Ensures complete collection of dust particles , Magnetic Separation System. Hence leaves no dust to environment. OPTIONAL ACCESSORIES Fully Automatic / Semi Automatic Cycle System PLC Control System Overhead Conveyor Moterised Cassette Type Dust Collection High manganese lining of cabin Magnetic Separation System

...more

Line Aerator

Salient Features Line Aerator are simple robust and dependable to Modern Engineering Practise. Specially designed for continuous duty for aerating the prepared sand Aeration takes place by means of two high speed rotors. The Rotors blades are lined with high wear resistant plastic material. The inner side of Line Aerators are lined with high wear resistant rubber material. Sand are scooped from the conveyor by the rotor blades and thrownagainst the chains fixed on the opposite side of the rotors. Ranges offered:6 Tons/Hr to 100 Tons/Hr.

...moreBe first to Rate

Rate ThisOpening Hours