Screenings Plant

trailbazer - world class mobile washing plants with innovative features that result in reliability and versatility. The "ws" series of wasing plants are designed for washing and screening of iron ore aggregates, manufactured sand, etc., for removal of silt, excessive fine materials, and other impurities. And to improve quality of product. Feed to screening plant from mobile belt feeder unit, model wf1200.

...more

VSI tertiary plant

railbazer - world class mobile crushing and screening plants with innovative features that result in reliability and versatility. The range includes plants that will attain capacities from 125 tph to 250 tph in demanding applications from iron ore to aggregate to recycling of construction rubble. Bazer crushers and feeders are modern equipments designed for heavy duty operation and long life. the "wv" series plants are fitted with bazer vertical shaft impact crushers and a hopper for pay loader or excavator loading. each "wv" series plant comes complete with crusher, belt feeder, discharge conveyor, hopper, chutes and electrical - "all in one" chassis. To start operations the vsi plant is positioned within feeding and receiving conveyors, connected to an electric supply source and crushing can begin. Each crushing plant is designed for ease of access to facilitate maintenance. The chassis are designed for rapid deployment and are easily transportable.

...more

Vertical Shaft Impactors

1 Piece (MOQ)

We are offering Vertical Shaft Impactors. These are built with an exclusive combination of standard features that provide value, performance and durability. These vsi are equipped with hydraulic lid lifter and available in rock-on-rock, rock-on-steel and steel-on-steel configurations. capacity range: 30 - 300 tph

Brand Name : BAZER

...more

Vibrating Screen

1 piece (MOQ)

We are offering Vibrating Screen bazer si/sh screens are packed with a host of features that make it reliable, robust and easily adjusted to a variety of tough applications in the aggregate, mining, cement and steel industries. These are available in single, double, tripe or four decks. Models available: a) inclined screens si1030 (size: 1000x3000 mm); si1535 (size: 1500x3500 mm); si1545 (size: 1500x4500 mm); si1850 (size: 1800x5000 mm); si1860 (size: 1800x6000 mm); si2060 (size: 2000x6000 mm). B) horizontal screens: sh1550 (size: 1500x5000 mm); si1850 (size: 1800x5000 mm).

...more

Vibrating Feeder

1 Set(s) (MOQ)

bhp is proud to introduce the bazer range of vibrating - feeders, packed with a host of features that make it reliable, robust and easily adjustable to a variety of tough applications in industries like aggregate, mining, cement, steel etc.bazer vibrating feeders provide greater efficiency with a longer service life over a wider range of rigorous applications. The feeder design allows for maximum equipment utilization. By decreasing your overall operating costs you get a longer payback and higher return on your investment. description of vibrating feeder parts: vibrating trough assembly static skirt assembly electromechanical vibrator vibrating trough mounting structure assembly helical coil spring hold on bolts

...more

Vertical Shaft Impactor Plant

We are offering vertical shaft impactor plant. Trailbazer - world class mobile crushing and screening plants with innovative features that result in reliability and versatility. The range includes plants that will attain capacities from 125 tph to 250 tph in demanding applications from iron ore to aggregate to recycling of construction rubble. Bazer crushers and feeders are modern equipments designed for heavy duty operation and long life. the "wv" series plants are fitted with bazer vertical shaft impact crushers and a hopper for pay loader or excavator loading. each "wv" series plant comes complete with crusher, belt feeder, discharge conveyor, hopper, chutes and electrical - "all in one" chassis. To start operations the vsi plant is positioned within feeding and receiving conveyors, connected to an electric supply source and crushing can begin. Each crushing plant is designed for ease of access to facilitate maintenance. The chassis are designed for rapid deployment and are easily transportable.

...more

Vertical Shaft Impactors

1 Piece (MOQ)

We are offering bazer range of vertical shaft impactors, which are built with an exclusive combination of standard features that provide value, performance and durability. These vsi are equipped with hydraulic lid lifter and available in rock-on-rock, rock-on-steel and steel-on-steel configurations. capacity range: 30 - 300 tph

...more

Vertical Shaft Impactor

bhp is proud to introduce bazer range of vertical shaft impactor, which is built with an exclusive combination of features that provide value, performance and durability. Hydraulic lid lifter. modular oil lube system externally adjustable feed large feed hopper with tube system for more feed tube life rock-on-rock design heavy-duty pedestal drive with double internal crushing self-aligning spherical roller bearings chamber fully protected motor mount and adjustable take-ups cast tub and lid liners auxiliary electrical control panel with: fully linear wear areas rpm gauge vibration detector hour meter open-lid crusher safety cut-off

...more

Track Screen

We are offering track screen. The tracked double-deck screen can be operated as a standalone screen to separate excavated soil, sand and gravel, plus building rubble mixed with high levels of earth and fine grain material. Thanks to the hydraulically opening feed hopper with oversized grain grating, the ts3600 can also be fed direct from a mobile rm100. Three defined final grain sizes can be produced in a single pass in combination with the rm100 and os100 power package equipped with oversized grain re-feeding system.

...more

Stone Crusher

1 piece (MOQ)

We are offering stone crusher we are offering full range of stone crushing and screening equipments viz. Jaw crusher, cone crusher, vsi, hsi, screens, feeders, conveyors ets. capacity range: 50 - 400 tph

...more

Screw Conveyors

BHP is proud to introduce its BAZER's Fine Screw Washer SW0900, packed with a host of features that make it reliable, robust and easily adjusted to a variety of tough applications in the aggregate, mining, cement and steel industries. BAZER Fine screw washer is ideally suited for removing material in application such as fines recovery, sand manufacturing, concrete reclamation, and municipal waste removal. Built with large, three stage gearboxes and outboard lower bearing assemblies, the units are designed for operating life and maintenance ease. BAZER's washing equipment is fabricated with heavy duty tubs, ensuring an operating life that will exceed that of the competition. The best feature of BAZER's washing product involves the extreme duty gearbox, designed for maximum torque, and slow speed operations. With oversize gears, these most critical components of the sand screw provide added safety for today's demanding operatorsOperating Principal Feed material enters the feed box and is distributed into the washer's setting pool. Internal and external baffles control the feed velocity and limit water current speeds and turbulence, enabling the washers to retain fines. Lighter products such as silt, excessively fine materials and other deleterious materials do not have time to settle and are carried away with the water over the long, adjustable side and end weirs. The settled material is augured up the washers by the spiral flights. Additional cleaning takes place by the abrading action of the material fractions. Excess water is drained back to the pooling area as the material is conveyed up and out the upper end of the trough.

...more

screening plants

trailbazer - world class mobile crushing and screening plants with innovative features that result in reliability and versatility. The "ws" series of wheeled screening plants are designed for heavy duty operation at mines and quarries and for contract screening. The screening plants are fitted with either circular motion inclined screens or elliptical motion horizontal screens.the trailbazer "ws" series screening plant has a double deck vibrating grid that screens out oversize, and a generous feed hopper from which a variable speed belt feeder extracts material onto a heavy duty double deck or triple deck vibrating screen, from which onboard product conveyors discharge the required sizes of product. The result is that the standard screening plant produces three or four sized products.the standard wheeled chassis comes complete with all equipment and conveyors including electrical control panels. To start operations, the screening plant is simply connected to an electric supply source, the conveyors are opened and screening can begin. Each screening plant is designed for ease of access to facilitate maintenance and replacement of screening media.

Type : Wheeled Inclined Screen

Power : External 46.7 KW

...more

Screening plant

We are offering screening plant. trailbazer - world class mobile crushing and screening plants with innovative features that result in reliability and versatility. The "ws" series of wheeled screening plants are designed for heavy duty operation at mines and quarries and for contract screening. The screening plants are fitted with either circular motion inclined screens or elliptical motion horizontal screens. the trailbazer "ws" series screening plant has a double deck vibrating grid that screens out oversize, and a generous feed hopper from which a variable speed belt feeder extracts material onto a heavy duty double deck or triple deck vibrating screen, from which onboard product conveyors discharge the required sizes of product. The result is that the standard screening plant produces three or four sized products. the standard wheeled chassis comes complete with all equipment and conveyors including electrical control panels. To start operations, the screening plant is simply connected to an electric supply source, the conveyors are opened and screening can begin. Each screening plant is designed for ease of access to facilitate maintenance and replacement of screening media.

...more

Sand Plant

1 Piece (MOQ)

We are offering sand plant. The bazer modular dry sand making plant ds 100 equipped with vertical shaft impactor vs1800, triple shaft horizontal vibrating screen sh1550-3a, tubular feeders, feed hopper, surge hopper and enclosed conveying systems like bucket elevator, screw conveyor etc. The main equipment and the transfer points are de-dusted through a bag filter.

Brand Name : BAZER

...more

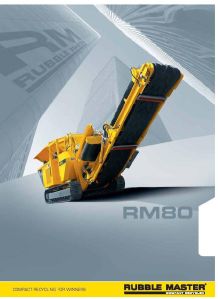

rubble master

The RM60 is the most compact RM crusher and perfect for newcomers to recycling. This semi-mobile crusher can be transported using a truck with drag-on hook system (for example) and is ready for operation in just 10 minutes. With a transport weight of just 12 tonnes, the crusher produces up to 80 tonnes of cubic high-quality grain per hour from rubble, asphalt and concrete. The RM60 is easy to operate and all service work can be carried out from the ground. With high-performance components such as pre-screens and final screens, you can create a complete recycling centre. Construction companies can then offer their services to businesses and communities, creating clearly defined, cost-effective recycling systems. Features: Adjustable throw angle, from 30 degree to 60 degree with 5 degree intervals Adjustable speed, variable from 675 to 875 rpm Huck bolted screen frame More efficient screening due to lower travel rate of material Oil splash lubrication system Crown shaved steel gears Lower overall height Self aligning spherical roller bearings Side plates of high strength alloy steel Adjustment of operating parameters to suit screening different material Discharge lips with liners Bolt on feed box with liners V-belt drive with drive guards Pivoted motor base Easy access to replaceable wear parts Side tension screen rails with hardware Applications Aggregate & construction industries Iron ore mines & plants Mining & mineral industries Sponge iron plants Options Available in double and triple deck designs for various applications Rubber deck / polyurethane / self cleaning deck

...more

Track Crusher

We are offering track crusher bhp infrastructure recently introduced the rubble master rm60 compact impactor plant and the rubble master rm80 track mounted impactor plant on behalf of hmh engineering gmbh of austria. We have also introduced the revolutionary rubble master ts3600, a track mounted screening plant with a vibrating grid. We are proud to inform you that we are distributors for hmh and market & support their products in india. capacity range: 100 - 300 tph founded in 1991 with the vision of creating perfectly compact crushing systems for a market in its infancy, hmh has developed into a strong international brand with high quality ideals: rubble master compact crushers have become a synonym for mobile crushing with an ever growing number of enthusiastic regular customers.

...more

Impact Crushing

1 Set (MOQ)

We are offering impact crushing bhp infrastructure recently introduced the rubble master rm60 compact impactor plant and the rubble master rm80 track mounted impactor plant on behalf of hmh engineering gmbh of austria. We have also introduced the revolutionary rubble master ts3600, a track mounted screening plant with a vibrating grid. We are proud to inform you that we are distributors for hmh and market & support their products in india. capacity range: 100 – 300 tph founded in 1991 with the vision of creating perfectly compact crushing systems for a market in its infancy, hmh has developed into a strong international brand with high quality ideals: rubble master compact crushers have become a synonym for mobile crushing with an ever growing number of enthusiastic regular customers.

...more

Recyclers

We are offering Recyclers. rubble master compact recyclers are the compact class for profitable recycling: versatile in use, powerful and stable in value. the produces homogeneous, cubic, high-quality grain from construction waste and natural rock on site economically and can be transported without special permits. thanks to innovation, top manufacturing quality and the extensive rm lifetime support program, rubble master users are able to fulfill the necessary tasks and requirements on all job sites and in any surroundings cost-effectively, and use the outstanding quality to earn a reputation as recycling specialists. because we are only satisfied when our customers are successful!

...more

Pan Conveyors

BHP Pan conveyors are designed to meet your material handling requirements, convey material both horizontally and up to 60 degrees inclination. Various designs of aprons and pans are available including the AFT pan design, deep bucket conveyor design and apron pan designs to meet any application requirements. The AFT pan design incorporates precision formed overlapping steel pans with lip contact between adjacent pans and between adjacent side plates of pans. Spillage is minimized even at steep inclines or when the pans articulate over the head or tail shafts. This design of pans is ideally suited for handling hot clinker in the cement plants or for conveying materials from fines to 150 mm lump size. The deep bucket conveyors are offered for handling materials up to 60 deg. steep inclination. Various apron conveyor designs are offered for diverse applications of primary crushed ore and rock, cement clinker, sugar cane, casting, solid waste, baled paper, slag, coal, pellets, hot sinter, steel pellets etc.BHP has supplied pan conveyors with center distance in excess of 110 meters and have the reputation of having supplied one of the world's largest pan conveyors to Indonesia with a vertical lift of 65 meters and inclination of 45 deg.

...more

nclined Vibrating Screens

BHP is proud to introduce its BAZER range of Inclined Vibrating Screens, packed with a host of features that make it reliable, robust and easily adjustable to a variety of tough applications in the aggregate, mining, cement and steel industries, these are designed and manufactured to satisfy the extreme operating duties found in different applications. Our Inclined Vibrating Screen includes double, triple and four deck configurations ranging from 1000 x 3000 mm to 2000 x 6000 mm. All units are built to meet the needs of today's demanding producers. The screen is shipped complete with sub-frames, motor mounts, v-belt drive guard, springs, and lined cross members. The result is a line of screening products that will compete in performance and durability with any comparable products available in the market. BAZER ranges of vibrating screens are available with options of: Circular motion inclined screens Linear motion horizontal screens Multiple flow banana type vibrating screens ( circular/linear motion) Dual flow vibrating screens ( circular/linear motion) Washing and dewatering screens Features: High strength steel side walls for durability Complete bolted design to avoid residual stress Generous sizing of bearings for long operating life Replaceable modular deck with carbon steel/spring steel/stainless steel wire mesh State of art oscillator - compact and rugged with adjustable lead and steel weights for stroke adjustment Amplitude variation from 50% to 100% Pivoted spring base allows variation of 2 degrees in deck angle setting Self tensioning motor base Easy access to replaceable wear parts Wire mesh tensioning by threaded bolts with self-aligning spherical washers Special design snubbers for smooth operation, preventing lateral movements Options Available in double, triple and four deck designs for various applications Rubber deck/polyurethane/self cleaning deck V- Belt drive or cardan shaft drive

...more

Mobile Crushing Plant

1 Piece (MOQ)

We are offering complete range of mobile crushing & screening plants for aggregate and mining applications, viz. Jaw crushing plants, cone crushing plant, vsi crushing plants, hsi crushing plants. Capacity of our plants ranging from 50 - 400 tph.

Brand Name : BAZER

...more

Jaw Crushing Plant

TRAILBAZER - world class mobile Crushing and Screening plants with innovative features that result in reliability and versatility. The "WJ" series of JAW CRUSHING PLANTS are designed for heavy duty operation at mines and quarries and for contract crushing. The range includes plants that will attain capacities from 150 TPH to 400 TPH in demanding applications from iron ore to aggregate to recycling of construction rubble. BAZER crushers and feeders are modern equipment designed for heavy duty operation and long life. The "WJ" series plants are fitted with BAZER single toggle jaw crushers and with BAZER heavy duty grizzly feeders that have a scalping option. The "WJ" series comes standard with a hopper for payloader and excavator loading. A stand-alone extension hopper is available for Dumper loading as an option. Each "WJ" series plant comes complete with crusher, feeder, discharge conveyors, chutes and electricals - "All in One" chassis. To start operations the jaw plant is positioned within feeding and receiving conveyors, connected to an electric supply source and crushing can begin. Each crushing plant is designed for ease of access to facilitate maintenance. The chassis are designed for rapid deployment and are easily transportable.The standard WJ 900 plant is also available in a skid design that is containerisable in a 40 foot container.

...more

Jaw Crushing Machine

HP Infrastructure brings you the BAZER range of versatile single toggle jaw crushers. BAZER Jaw Crushers offer customers high capacity, low maintenance and application versatility. Quality BAZER Components ensure reliable operation. With a moderate investment cost, our jaw crushing system offers operators the flexible production and high capacity output necessary to remain competitive. BAZER Jaw Crushers are suitable for all types of applications like aggregate, quartzite, sandstone, iron ore and other metallic ores. Designed to excel in even the most difficult working conditions, BAZER jaw crushers have proven their worth as the true workmate in various crushing applications. Features: Large eccentric shaft for greater stroke in the upper chamber High angle toggle plate increases stroke in lower chamber Large flywheels have greater inertia for crushing in toughest applications Deep pitch gripper jaws for maximum reduction Jaws available in options of half bellied and full bellied High rib concentration for toggle support Drop forged, heat-treated shaft to withstand the pressures of high reduction Heavy duty stress-relieved welded steel base for higher durability Spherical self-aligning roller bearings Hydraulic toggle seat adjustment Close tolerance machining of jaw backs and seating surfaces Reversible key plates for extended life

...more

jaw crushing

TRAILBAZER - world class mobile Crushing and Screening plants with innovative features that result in reliability and versatility. The "WJ" series of JAW CRUSHING PLANTS are designed for heavy duty operation at mines and quarries and for contract crushing. The range includes plants that will attain capacities from 150 TPH to 400 TPH in demanding applications from iron ore to aggregate to recycling of construction rubble. BAZER crushers and feeders are modern equipment designed for heavy duty operation and long life. The "WJ" series plants are fitted with BAZER single toggle jaw crushers and with BAZER heavy duty grizzly feeders that have a scalping option.The "WJ" series comes standard with a hopper for payloader and excavator loading. A stand-alone extension hopper is available for Dumper loading as an option. Each "WJ" series plant comes complete with crusher, feeder, discharge conveyors, chutes and electricals - "All in One" chassis. To start operations the jaw plant is positioned within feeding and receiving conveyors, connected to an electric supply source and crushing can begin. Each crushing plant is designed for ease of access to facilitate maintenance.The chassis are designed for rapid deployment and are easily transportable.The standard WJ 900 plant is also available in a skid design that is containerisable in a 40 foot container.

...moreBe first to Rate

Rate ThisOpening Hours