Aluminum JCB Pump Body Casting

300 Per Piece

10 Piece (MOQ)

Steel and CI Casting Components

300 - 6,000 Per PIECE

2000 Piece (MOQ)

We also undertake to supply Steel and CI Casting and Machined Parts as per drawings and specifications or samples ranging from 20gms to 5000 gms with high accuracy.

Best Deals from Casting Parts

Aluminium Die Casting

Get Price Quote

We provide Aluminium Die Casting that offers the desired performance for a long time due to its accurate dimensions, improvised design and use of high grade aluminium metal. The quality brought forth in this range makes our aluminium die casting a highly appreciated product amongst the clientele that we cater to.

Shot Sleeves

Get Price Quote

Brass Casted Two Piece Loop

100 - 500 Per Piece

10000 Piece (MOQ)

SUDHAN INDIA LIGHTING PVT. LTD. are Faridabad (India) based Manufacturer, Exporter & OEM Supplier of Precision Brass Turned Components Supplying all over India as well as offshore regions like USA, UK, Europe, Middle-east, Asian countries. Our components technologically advanced and have high level of performance that has earned them global recognition.

Aluminium EPS Mould Die For Crockery Set

250,000 Per Piece

1 Piece (MOQ)

EPS moulds play a vital role in the manufacturing of EPS products, offering versatility, efficiency, and sustainability. The ability to create complex shapes, coupled with streamlined production cycles, makes EPS moulds a valuable asset for various industries. With ongoing advancements in technology and design, EPS moulds continue to evolve, further enhancing the capabilities and possibilities of EPS manufacturing. As a result, EPS products will continue to be at the forefront of innovation, meeting the diverse needs of industries while promoting a greener and more sustainable future.EPS moulds are specifically designed tools used in the production of EPS products. They are typically made from high-quality aluminum or steel, ensuring durability and precision during the manufacturing process. The moulds consist of two parts: the male part, known as the core, and the female part, called the cavity. These parts fit together to create a hollow space that defines the final shape of the EPS product.Benefits of teflon coating mould: Nonstick Properties: Teflon coating is famous for its exceptional nonstick properties. It creates a smooth and low-friction surface that prevents sticking of various substances, such as food, adhesives, chemicals, and more. This property is especially useful in cookware, where it allows for easy food release, reduced need for oils or fats, and effortless cleaning. Heat Resistance: Teflon coatings have excellent heat resistance, making them suitable for high-temperature applications. They can withstand temperatures up to 260°C (500°F) without degrading, making them ideal for use in ovens, grills, and other cooking appliances. The heat resistance of Teflon coatings ensures durability and longevity even under extreme temperature conditions. Chemical Resistance: Teflon coatings exhibit exceptional resistance to chemicals, acids, solvents, and corrosive substances. This property makes them highly valuable in industrial settings where materials come into contact with aggressive chemicals. Teflon coatings provide a protective barrier that prevents chemical attacks, corrosion, and degradation of the underlying substrate. Water and Oil Repellency: Teflon coatings offer hydrophobic and oleophobic properties, meaning they repel water and oil. This feature is useful in applications where the prevention of liquid absorption or adhesion is required. Teflon-coated surfaces remain unaffected by water, oils, and other liquids, reducing staining, facilitating easy cleanup, and preventing surface damage. Electrical Insulation: Teflon coatings are excellent electrical insulators. They possess high dielectric strength and low surface energy, making them resistant to electrical current and minimizing the risk of electrical short circuits or malfunctions. Teflon coatings are commonly used in electrical components, wiring, and circuit boards to provide insulation and protect against electrical hazards. Abrasion Resistance: Teflon coatings offer exceptional abrasion resistance, providing protection against wear and tear. They can withstand friction, impacts, and mechanical stress, ensuring the longevity and durability of coated surfaces. This property is particularly beneficial in industrial applications where components are subjected to heavy use or abrasive environments. Easy Cleaning and Maintenance: Teflon-coated surfaces are easy to clean and maintain due to their nonstick and stain-resistant properties. Most substances can be easily wiped off the smooth Teflon surface, reducing the need for harsh cleaning chemicals or vigorous scrubbing. This feature is advantageous in various industries, including food processing, automotive, and manufacturing, where cleanliness and efficiency are paramount.

Centre Housings, Aluminium Pressure Die Casting Components

Get Price Quote

We are offering centre housings, aluminium pressure die casting components.

Aluminium Gravity Castings

325 - 500 Per Piece

Aluminium Gravity Die Casting Parts

Get Price Quote

100 Piece (MOQ)

Gravity Die Castings

Get Price Quote

From the sourcing of raw material till the final dispatch, our quality auditors keep a stern eye on every sage. We are strategically based in Haryana(India) and are in proximity with the resources required for easy production process.

Cast Iron Plungers

Get Price Quote

We are offering cast iron plungers of all sizes and dia duly grind and machined.

Plunger Tip

Get Price Quote

1 Piece(s) (MOQ)

Plunger Tip RAGA Manufactures quality Die Casting Consumables amongst which Plunger Tips and Shot Sleeves are one of the favorites with the die casters all over the world. RAGA’s R&D & Design with State of the art CNC/SPM manufacturing and inspection facility carry out continual research into application of Plunger tips. The ongoing quest for optimizing Shots has lead RAGA to indigenous and innovative designs for Plunger Tips.

Ci Casting

90 Per Kilogram

1000 Kilogram (MOQ)

die cast plastics moulding components

Get Price Quote

We are assisted by a team of professional quality experts who check our products at different stages such as production, packaging and delivery. We are highly acknowledged for delivering the orders within the stipulated time frame as we have excellent transit facility.

Press Tool Dies

Get Price Quote

With the help of our competent team of professionals, we have been able to manufacture, supply and export a broad array of Press Tool Dies. These dies are manufactured employing latest machines following standards & norms of the industry.

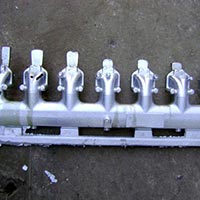

Traub Casting Stopper

700 Per Piece

1 Piece(s) (MOQ)

Customised Aluminium Die Casting Parts

10 - 2,000 Per Piece

100 Piece (MOQ)

At our state-of-the-art facility, we specialize in the precision crafting of aluminium die-casted and machined parts. Tailored to meet the diverse needs of industries ranging from automotive to energy, our products stand at the forefront of innovation. Whether it's for robust construction equipment, intricate agricultural machinery, or the sleek components of home appliances, our commitment to customization and quality sets us apart in the dynamic manufacturing landscape. Best source for aluminium die casted and machined parts from India.

Pressure Vessels

Get Price Quote

02 Piece(s) (MOQ)

We are offering pressure vessels. Pressure vessels for ro plant,softener plant,dimineral plant,industrial filtration plants. Are available in all size.

Aluminium Gravity Casting

Get Price Quote

We are the main supplier of this services.

Motor Cover Aluminium Die Casting

90,000 Per Piece

Die Casting Machine

Get Price Quote

Die Casting Machine under the guidance of qualified and highly experienced engineers. The machines are built with best quality materials and components.Machine base is extra strong structural construction, which supports the injection system on its extension. Part of the base is attached with oil reservoir to accommodate a good quantity of hydraulic oil and is provided with oil gauge and digital thermometer.

auto die casting

Get Price Quote

Being a pro in configuring a desired design with required quality; Star Auto Solutions have made a remarkable impact in the industry of engineered products. We have always met a client’s requirement without delay and the same promise holds true for our die casting engineering. Simple science about die casting says it is a process of metal casting—where molten metal is poured into mould cavities under high pressure. And second important point is that these are made out of non-ferrous metals. So, zinc, aluminium, lead, copper, magnesium and tin alloys are used for creating die casting parts. Precision engineering for die casting is possible through up-to-date infrastructure. Apart from customer satisfaction, we continuously work towards value engineering. We at Star Auto are engaged in research, improvement and upgradation of our products by new equipment and technology. This prepares us to face challenges and give standard product to our valued customers. Each product is taken care with an aim to provide durability and strength. We concentrate on saving cost for our customers and give them best in technology. You can rely on us for aluminium housings, Chassis brackets, aluminium brackets, aluminium pumps, aluminium hub covers, and aluminium frame covers, aluminium die casting products, industrial aluminium connectors, and white goods industry parts. We also supply the products with powder coating or wet painting. We have developed a niche in delivering customized products. We are quite flexible and fast in providing products either of high strength or leak proof or low porosity or any other. Further our trained and professional engineers take guarantee of quality and timely delivery of products. Each product is checked for quality by our team of engineers before being dispatched from workshop. Each is graded and then sent to sales and marketing team. At Star Auto Solutions, life is not easy for our technicians and engineers; they are continuously working to bring an improvement. Every day is a new challenge for them and our engineers are forever studying any new technological breakthrough in die casting, so they can incorporate it and deliver highly advance, durable and low cost maintenance products.

Die Casting Parts

Get Price Quote

we are offering Die Casting Parts. Star Auto Solutions Offer you Die Casting Parts Being a pro in configuring a desired design with required quality; Star Auto Solutions have made a remarkable impact in the industry of engineered products. We have always met a client’s requirement without delay and the same promise holds true for our die casting engineering.

Pressure Sensors

Get Price Quote

We are a well-known Pressure Sensors Manufacturer and Exporter. Pressure Sensors, offered by us, are made by using top quality raw materials. We make available premium Pressure Sensors that are highly appreciated for their accurate dimensions and reliability. We offer Pressure Sensors in various specifications to suit distinguished requirements of clients. Take Minimum Order Quantity : 250 pieces for all products

Gravity Die Castings

Get Price Quote

Our company is instrumental in bringing forth wide range of Gravity Die Castings by using high gravity system. These Gravity Die Castings are manufactured at our fabrication unit utilizing the highest quality raw materials coupled with cutting-edge technology. These castings are widely demanded in automobiles, plastic toys industries to fill molds with molten materials. Our Gravity Die Castings are dimensionally accurate and corrosion resistant.Details : In the permanent mould casting process, the molten metal is poured from a vessel of ladle into the mould, and the cavity fills with no force other than gravity, in a similar manner to the production of sand castings, although filling can be controlled by tilting the die. The advantages over sand castings include better surface finish, and better mechanical properties, which occur due to relatively fasted cooling rates that occur in, die-casting. Die-casting is a process in which the molten material is forced into a steel mold or die-casting. This process is usually accomplished using high-pressure injection systems. gravity die casting uses the force of gravity, instead of high pressure means, to fill a permanent mold, or die, with molten material

Pressure Vessels

Get Price Quote

We are the manufacturer of Pressure Vessels starting from 50 ltrs capacity to 100M3 capacities, both in horizontal and vertical design, for working pressures starting from 7kg/cm2(g) to 30kg/cm2(g), for various applications including compressed air, DM plants, CO2 storage.   The design codes followed are latest editions of IS2825, ASME, Section VIII, Div I.  The Material of construction is as per customer requirement / application which include IS2062 GrB, IS2002, SA516 Gr60 / 70, SS304, SS304L, SS316 etc. The manufacturing is done under strict quality control procedures adhering to our internal quality assurance plan (QAP), NDT testing including radiography, UT, MPI,  third party and customer inspections. We have successfully installed more than 8000 pressure vessels and still counting for more .

brass pressure die casting

Get Price Quote

In Pressure Die Castings, Liquid Metal With Immense Pressure Is Infused Inside The Metal Molds. It Is A Reliable, Abrupt And An Economical Technique To Manufacture Metal Components In A Bulk.

Die AND Mould Spares

Get Price Quote

Our collection of industrial products comprises of qualitative die spares that are procured from reliable vendors who are well-known for their quality standards. We import die spares such as Spool Retainers, Wear Plates, Guide Post/Pillar Sets, Cam Units and Ball / Pin Plunger (lifters) charged with springs as well as Nitrogen Gas from Italy and Japan against requirement of customers. We also offer Sprue bushes, Sine plate, Push back pins, Date marking pins, Date inserts, Parting locks, Ball Cages etc.

Pressure Sensors

Get Price Quote

We are offering pressure sensors.we are a prominent manufacturer and distributor of pressure sensors, which are manufactured using high grade materials. Popular among the clients for their good performance and matchless quality, our pressure sensors have helped us to carve a niche for ourselves in both the domestic and international markets. specifications : u.s. Made beryllium copper diaphragmvoltage : 6v to 24vtest standards in compliance with sae j1810 , is:5439 types : warning contact, common groundwithout warning contact, common ground.without warning contact, insulated return. features : robust constructionreliable even under tough environmental conditionsuseful for measuring gas or liquid pressurehighly accurate best used for : automotive useagricultural equipmentindustrial machinerymarine and off-road applicationsheavy duty diecast designgerman nickel chrome resistance wirephosphor bronze wiper with silver coated contact

Transfer Fingers

Get Price Quote