Cementing Rubber Plugs

Get Price Quote

We deal in Cementing Rubber Plugs are offering cementing rubber plug designed with plastic core and aluminum core. This helps to compliment its line of plugs to decrease drill out times. The Cementing Rubber Plug is used for separating the cement slurry from the mud. Our range of Cementing Rubber Plugs have solid top plug and the bottom plug is hollow. They can all be drilled out with PDC bits. The material of the Cementing Rubber Plug body is Acrylonitrile- Butadiene rubber. It is heat-resisting and tough and the core is made of a glass-filled high strength Phenol resin core. Attributes : The tapered base fits the cavity of the bottom plug for a positive seal. The fins and tail section provide positive wiping action. Fins also serve as a seal while cementing A rubber diaphragm at the top of the plug ruptures after the plug is seated allowing cement to flow through. The cementing rubber plugs are available in sizes 4 12" to 20". It prevents the mud from blending into the cement slurry to influence the cementing quality.

Cementing Plugs

Get Price Quote

aluminium core cementing plug to Compliment its line of plugs to decrease drill out times. The cementing plug is used for separating the cement slurry from the mud .It can prevent the mud from blending into the cement slurry to influence the cementing quality. Structure features: The top plug is solid .The bottom plug is hollow. They can all be drilled out with PDC bits. The material of the plug body is acrylonitrile- butadiene rubber. It is heat-resisting and tough. The core is made of a glass-filled high strength phenolic resin core. The tapered base fits the cavity of the bottom plug for a positive seal. the fins and tail section provide positive wiping action. Fins also serve as a seal while cementing. A rubber diaphragm at the top of the plug ruptures after the plug is seated allowing cement to flow through.

Best Deals from Cementing Plugs

Cementing Plugs

Get Price Quote

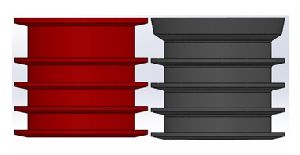

Plugs are used during cementing operations to help remove dispersed mud and mud sheath from the casing inner diameter and minimize the contamination of cement. A bottom plug is pumped ahead of the cement slurry and behind the spacer. It wipes any remaining dispersed mud from the inner diameter of the casing as it moves down the string. The top plug wipes center from the inner diameter of the casing and then seal at the float collar, resting on the on the bottom plug and causing a pressure increase at the surface including that the cement has been displaced. Top and bottom plugs are always different color. Bottom plugs are red and top plugs are black.

top cementing plugs

Get Price Quote

top cementing plugs, Centralizer, Float Shoe, bottom plugs, Hammer Union