Dual Line Lubrication System

Get Price Quote

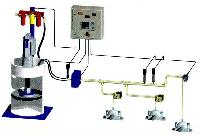

The Dual line Grease/oil lubrication system is a centralised lubrication system in which grease/oil is fed to lubrication points in measured quantity through dose feeders from a common source. In the system there are two main lines which work alternatively. The system has a control panel that helps in easy operation of the system. Components : Motorized Pump StationExcellent Control PanelReliable Dose FeedersQuality Tubing and FittingsEnd Pressure RelayInbuilt Filters Characteristics : Easy to work withCost- efficientUse of Advanced TechnologyHuge Discharge Capacity

centralised lubrication systems

Get Price Quote

Best Deals from Centralised Lubrication Systems

centralised lubrication systems

2,250 Per Piece

1 Piece(s) (MOQ)

Dual Line Lubrication System

Get Price Quote

2 Pack(s) (MOQ)

ss enterprises manufactures and suppliers an exclusive dual line grease lubrication systems in faridabad, haryana, india. in this system there are two lubrication outlets, for two lines. the system starts to deliver the grease in line-1 and fills this line up to set pressure. when the pressure of this line reaches to the set pr., the system stops to delivers the grease in line 1 and starts to deliver the grease in line-2 fills it upto set pressure. when the set pressure in line -2 is built up then it again starts filling the grease in line.

CGL- Centralised Grease Lubrication systems

250,000 Per Set

1 Set(s) (MOQ)

By utilizing skills of our dexterous workforce, we are offering a comprehensive assortment of Dual Line Lubrication System. We manufacture this system by employing optimum quality steel, metal and modern technology. Our offered system has been appraised for its smooth fabrication, high functionality, proper installation, reduced maintenance and long service life. Furthermore, we can offer this system to our esteemed clients at affordable rates. Features: Non corrosive Precise design Easy installation Description: Lubrication systems engineered with the Dual Line system are generally used on large scale machinery and in harsh operating conditions to lubricate multiple points on large machines. The system can grow to a very complex one with a length that often can exceed 60 meters. The large section of pump packages together with many custom design options allows any lubrication system to be developed reliably and cost-effectively.

Dual Line Lubrication System

Get Price Quote

Dual Line Lubrication System that we offer is manufactured by our experienced professionals using premium components with the aid of advanced technology. It is known for its longer functional life and smooth functionality. We are one of the reputed Manufacturers, Exporters and Suppliers of Dual Line Lubrication System from Haryana, India. We are efficient enough to process retail as well as bulk orders for Dual Line Lubrication System even at short notice period. Features : Low power consumption Trouble free performance Corrosion free coating Easy to install Specifications : Dual lubrication system, a parallel type lubrication system, has two main lines running across the length and breadth of the equipment. Metering devices called "dose feeders" are installed close to the lubrication points. High pressure grease pump feeds the entire system and has options of manual, motorized and pneumatic drive to choose from. Pumping Station : With Safety Valve, Pressure Gauge and Lubricant filter Pumps all type of oils and grease (upto NLGI 2) Motorised Pump : No. of outlets - One Max. Op. Pressure - 400 Bar Reservoir Capacity - 50 / 100 Litres Lubricant output - 9litres/hr and 14 Litres/hour Drive - Electrical Motor with gear box Power supply - 415V, 50Hz, 3 phase, 0.75KW Pneumatic Pump : Mounted on 180 kg grease barrel Manual Pump : Max. Op. Pressure - 400 Bar Reservoir Capacity - 2.5 / 4 Litres Change Over Value : Hydraulically operated with indicator pin with proximity switch Option of motorised valve and solenoid operated valve available Dose Feeders : Have adjustable output and indicator pin for monitoring Options available in dose outputs and in construction type - modular and mono-block Inlet connection - 3/8"BSP (Female) Outlet connection - 1/4"BSP (Female) Control Panel For controlling the operations of centralised system having following features : Lubrication cycle count Off-time setting Reservoirs low level indication Fault Annunciation by audio/visual indication Motor Overload / short circuit Protection

Lube Oil Systems

Get Price Quote

The Lube Oil Systems supplied by our company come with pumps which are driven by electric motors and are mounted on base frames with filters and safety valves for complete operation of the system as a single unit. The Lube Oil Systems are actually compact units of pumps, motors and other such things with varying specifications. Applications Of Lube Oil Systems Cement industryPaper industrySteel industryPower sector

Dual Line Grease Lubrication System

Get Price Quote

We bring forth the most qualitative Dual Line Grease Lubrication Systems. This system comprises of two lubrication outlets, for two lines. The system starts to deliver the grease in line-1 and Fills this line up to set pressure. When the pressure of this line reaches to the set pr., the system stops to delivers the grease in line 1 and starts to deliver the grease in line-2 fills it upto set pressure. When the set pressure in line -2 is built up then it again starts filling the grease in line -1. This process continues up to the set time. Dual Line System works with maximum pressure of 500 bars with 11 cc/ min discharge per outlet continuously. The system is not hindered by blockage in one line and continues to function smoothly. The entire system is controlled by an electric control panel.

Dual Line Lubrication System

Get Price Quote

Dual line system is used where large distance in lubrication point. This is high pressure pump and use in steel plants, cement plants, Turbine generator, furnaces, sugar plants, spong iron plant etc. Dual line lubrication system comprising of a single pumping station having pumping elements and fitted on the outer periphery of the housing. Reservoir also mounted on housing and fitted on base plate with motor, gear box, change over valve, pressure gauge etc. In dual line lubrication pump the pumping elements push the grease at high pressure (up to 250 Kg/cm2) with the help of cam. Cam is driven by speed reduction gear, Grease feed in change over valve from pump elements. Change over valve is to deliver grease through one of the out let ports alternatively after receiving signal from end pressure relay, Distribution of grease at different lubrication point done by Dose feeder and this pump operate by the control panel. Product Code End Pressure Relay It sense the end pressure and gives signal to change over valve through control panel. For checking the pressure two pressure gauge are provided. Electric Control Panel Electric control panel is required for operate the lubrication system. Panel has the features main on indication, Manual and auto mode indication, Line one and two on indication, Line fault indication, Motor trip indication, Emergency stop button and other standard control. This control panel is available as per customer requirements. Grease Transfer Pump Grease transfer pump is pneumatic version. This pump is directly mounted in the barrel. It transfer the grease to the reservoir of pumping station

centralised lubrication systems

Get Price Quote

Lube Seal Oil System

Get Price Quote

Grand Prix design, manufacture & supply Lube/ Seal Oil Systems for Compressors & Turbines to supply the lubricating oil at desired temperature & pressure after removal of solid contaminations up to 1 micron rating having a max flow rate of 1600 LPM & pressure rating 60Kg/cm2g.

Dual Line Grease Lubrication System

Get Price Quote

Techno Drop Manufactures an exclusive Dual Line Grease Lubrication system. In this system there are two Lubrication outlets, for two lines. The system starts to deliver the grease in line-1 and Fills this line up to set pressure. When the pressure of this line reaches to the set pr., the system stops to delivers the grease in line 1 and starts to deliver the grease in line-2 fills it upto set pressure. When the set presure in line -2 is built up then it again starts filling the grease in line -1. This process will continue up to the set time. It can be used in heavy Industrial Machinery such as steel plants, sugar plants, Cement plants, Paper plants and turbines etc. Dual Line System works with max. Pressure of 500 bars with 11 cc/ min discharge per outlet continuously. It can deliver the grease in pipe line of up to approx. 60 mtr. Length. In case of any blockages in the one outlet of system, the system will be remain in operation. After complete functions of this system has been controlled by the electric control panel.

centralised lubrication systems

Get Price Quote

centralised lubrication systems

Get Price Quote

dual line high pressure grease lubrication system

Get Price Quote

dual line high pressure grease lubrication system, Lubrication system

Air Oil Mist Lubrication System

Get Price Quote

Dropco manufactures wide range of oil , oil mist lubrication systems, air oil mist lubrication system and grease mist lubrication system as per user requirements.the performance of these systems are excellent. The company has developed a lots of special mist lubrication system as per customer's requirement. These systems are suitable for spray lubrication. The ratio of mixture of air & oil at the outlet can be adjusted as per requirement.

centralised lubrication systems

Get Price Quote

centralised lubrication systems, automatic motorised lubrication pump

Dual Line Lubrication System

Get Price Quote

Dual Line Lubrication System, connector block, Plunger Pump Element Assembly

Dual Line Lubrication System

Get Price Quote

Dual Line Lubrication System, Manual Grease Pump, oil injectors

Dual Line Lubrication System

Get Price Quote

Dual Line Lubrication System, Lubrication Timer, Manual Grease Pump