manual batch coding machine

1,950 Per Piece

10 Piece (MOQ)

Metal Sheet Bending Machine

50,000 Per Piece

1 Piece (MOQ)

Best Deals from Construction Machine

Rim Straightener

Get Price Quote

We manufacture excellent quality Rim Straightener that is an equipment used for the straightening the wheel rim. Our Wheel Rim Straightener is made up from the premium quality raw materials under the strict vigil of the experts. Wheel Rim Straightener provided by us is in high demand in the market for dimensional accuracy, robust structure and high durability. We are well reckoned as one of the overruling Accurate Rim Straightener Manufacturers, based in India. We provide Wheel Rim Straightener at a very brisk pace and that too at affordable price. Advantage : It is double Dies at center removes bends accurately and heavily damaged rims at corners can also be straighten accurately. Accessories : Supplied Accessories Die attachments for 4",41/2",5",51/2" rim width. Optional Accessories : Die attachments for rim with 6" which includes; Tata Safari, Bolero etc. Service & Warranty : The machines have a full one year warranty covering all parts. Consumable, broken parts, damages due to negligence are not covered under warranty. The defective parts will be repaired or at our option, replaced free of charge for labour or materials provided that: The machine is accompanied by proof purchase i.e. date of sale. The machine is not tampered with. The machine has been operated from Standard mains supply using a CVT. No parts out of the scope of warranty are damaged. We have a fullyequipped servicecentre withall required spares inventoryand calibration facilitiesof all our instrumentsand all your instrumentsare handled byexpertsonly. Downtimeis keptminimum. Research & Development : R&D is constantly active to increase the quality and capability of our instruments. Moreover it is constantly in touch with the sales to hear their demands for new models and for upgradation of existing models. Latest type of computer CAD/CAM facilities are used for electronic and mechanical designing of instruments. Automatic Rim Straightening Machine Model Universal Electro-Mechanical Easy to Operate Suitable for All Rims to Cars and Jeeps Repairs Edges & Centre Bend.

Decoiler Straightener with Feeder

Get Price Quote

1 Set(s) (MOQ)

We are largest manufacture exporter decoiler, straightener & feeder for complete coilpress feeding line. samay-asia provide top quality products for complete presscoil feeding line for punching press.

automatic bar cutting machine

Get Price Quote

Municipal Solid waste incinerator Plant

1,200,000 Per piece

1 piece (MOQ)

NEC25 Manual Conduit Pipe Bender

Get Price Quote

10 Piece (MOQ)

Fly Ash Brick Making Machine

Get Price Quote

1 Piece (MOQ)

Fixed Dipper

Get Price Quote

We are counted among the successful Manufacturers and Suppliers of Fixed Dipper. The dippers we offered by us are known for their long functional life and excellent quality. Courtesy our brilliant logistics network, we are capable of delivering bulk orders of these within the promised span of time. We offer these at affordable rates.

Digital Crush Testing Machine

1 Per Piece

1 Piece (MOQ)

Single Spout Mortar Packing Machine

300,000 - 600,000 Per Piece

1 Piece (MOQ)

Centrifuge Machine

135,000 Per piece

1 piece (MOQ)

We are engaged in offering our clients a high quality range of centrifugal machine. The offered machine is widely demanded in number of food processing mills for separating paddy. It is manufactured using high grade stainless steel and contemporary techniques in compliance with set industry norms. Our offered machine is made available in different specifications for our clients with different choices. Clients can avail this machine from us at pocket friendly price.

Mini Mobile Reversible Concrete Batching Plant

435,000 - 440,000 Per Nos

1 Piece(s) (MOQ)

Only high-grade packaging material has been used for the safe packing of the products. Thus, we make sure that our customers will get only damage-free products from our end. We follow a stringent quality procedure to ensure that only a qualitative range of products should be delivered at buyer's end. Specifications: Capacity: 103m/Hr,153m/Hr Tyre mounted: 04 Tyre mounted Base frame of Heavy duty channel: 125x50x6 mm (Sail / Vizag), Drum Motor: 10 HP-15 HP Water Motor: 1 HP Monoblock pump Power Pack Motor: 3HP motor Water tank capacity: 180 ltrs Approx Price: Rs 4 Lakh / Piece

Concrete Chair Mould

12,000 Per Set

01 Set(s) (MOQ)

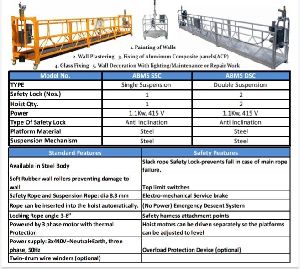

Cradle machine

200,000 - 500,000 Per Set

1 Set(s) (MOQ)

manufacturing in india faridabad aditya building maintanence services totally indian

Section Straightening Machine

Get Price Quote

Tejinder Drawing Section Straightening Machine, cutting, Polishing is first of its kind manufactured indigenously for Cold Bright Bar Drawing. It gives Bright Bar Drawing, straightening of any rolled, Drawn, Ferrous or Non Ferrous solid section in cold condition. This machine is engineered to give trouble free long life.

eps block molding machine

3,500,000 - 6,500,000 Per Set

1 Set (MOQ)

all type thermocol manufacturing

Vibration Table

Get Price Quote

36x30inch Jaw Crushing Machine

800,000 - 7,000,000 Per Piece

1 Piece (MOQ)

Jaw Crusher, as the name suggests, works on the same principle as the human jaw. It has one stationary jaw (like the upper teeth set) and the other movable (like the lower teeth set) with the material to be crushed (food to be chewed) fed inside the two jaws (mouth) and crushed (chewed) to the desired size and discharged (swallowed) to accommodate fresh input of material (food). "CCS OSTEM" strives to attain the same perfection for its Jaw Crusher like the human jaw devised by Mother Nature!!! Being at the primary crushing stage of the Crushing & Sereening Plant, the Jaw Crusher is subject to heavy shock load. Performance wise, it must discharge output material sized enough to match with the subsequent crushing stage, and at compatible output capacity. It is also essential to incorporate features to with stand the adverse conditions prevailing at remote sites. The "CCS OSTEM" Jaw Crusher has heen designed and manufactured keeping all theserequisites. Salient Features Based on the Single Toggle Mechanism, the Toggle Plate in "CCS OSTEM" Jaw Crushers is oriented in a manner so as to produce magnified stroke for best results. Proper Cavity Opening vs. Cavity Depth ratios for all models prevent blockage of the material to be crushed. Smooth flow of the material within the machine enhances crushing capacity. Main Body, made from tested quality M.S. Plates of required thickness, is duly annealed at. our in-house computerized oil fired furnace. The Swing Jaw Crank Shaft Assembly, which also houses theinner bearings, has been designed to prevent any dust entering it. Bearings are fit using latest technique for longevity and optimum performance. "CCS OSTEM" Jaw Crushers incorporate sturdy Hydraulic arrangement for adjustment of Closed Side Setting (C.8.8.). The design is operator friendly and flexible for varied settings. All cast items used are as proper industry standards in terms of metallurgy and processing. Wear resistant high grade austenitic Manganese Steel is used for Jaw Plates and Side Plates.

Solid Carbide Cutter

Get Price Quote