Continuous Hardening Furnace

Get Price Quote

We have installed all the requisite amenities, necessary for making safe side deliveries. Our product is available in nontoxic and industrial-grade packaging materials that ensure the products are safe from damage and reach buyers in brand new conditions.Features : Rugged construction High efficiency Hassle free performance

Continuous Heat Treatment Furnace

Get Price Quote

We are engaged in manufacturing Continuous Heat Treatment Furnace that provides strength to products through heat processing. The Continuous Heat Treatment Furnace range is available in resistance heated and gas/oil fired versions. The Continuous Heat Treatment Furnace range offered by us can accommodate a variety of materials and treatment goals through the use of optimized settings for heating and cooling temperatures, wait times, heating and cooling speeds, and ambient conditions. Our Continuous Heat Treatment Furnace comes with attendant equipment such as controllers, ambient gas generators, and cooling units.

Best Deals from Continuous Furnaces

Continuous Heat Treatment Furnace

Get Price Quote

These furnaces are capable of operating at temperature upto 1000 Deg.C. The items to be heat treated are charged into the furnaces on trays and the loaded trays are pushed into the furnace one by one. After heating and soaking, the material comes out of the furnace and removed from the platform. These furnaces are suitable for normalising, stress relieving and other heating process of various types of components. The oil consumption is 60-65 ltrstonne when steel forgings are normalised or hardened.

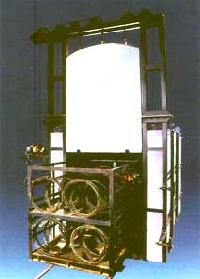

Continuous Hardening AND Tempering Furnaces

Get Price Quote

The capacities of continuous hardening and tempering furnace line include natural hardening and tempering, hardening and carbon restoration and shallow case carburizing. Through this equipment a better quality material is obtained at a time and there is no need to wait for periodic intervals. In addition to this, fostering of heat treated component is also not needed. Continuous coneyorised heating and quenching system is an ideal plant. This also assures a high degree of heating and quenching when few components are added at a time. This also assures consumption of lesser energy and high degree of consistency. Along with this case depth, hardness and physical properties of material can also be maintained according the needs. These plants that have conveyorised auxiliary process for loading. Washing and tempering usually are fully automated in nature. For loading process, metered loading, weight feed and reciprocating feeders can be employed. Wash machines gives high intensity steam wash. These are ultrasonic and allow degreasing and line centrifuge. Drying and dirt filtration is also eased along with oil separation and salt recovery. . Shell of the furnace has microporous installations. It has an alloy belt that has raised edges. auto-electric tube heaters with multi-zone thyristorised temperature control are present. Hot belt system allows waste heat recovery from atmosphere. Quenching process is facilitated by continuous dirt removal. Temperature and flow level controls and variable agitation. Along with this, high convention tempering, jet heating system, steam tempering facility and nitrogen atmospheric capacity is present. Finally proper control is assured with the help of computer HMI for user interface. SCADA programing is also employed that works in different reporting formats.

Continuous Mesh Belt type Furnaces

Get Price Quote

Process Capabilities: Hardening Sintering Brazing Annealing Tempering Normalizing Homogenizing High Productivity with consistent results characterize this mesh belt type furnace with provision of heating & cooling in protective or reducing atmosphere. The furnace performs very efficiently with scale free product and ensures lesser variability in results. The furnace is available in various sizes and specifications depending upon application Salient Features: Rigid and durable construction due to better reinforcement by rolled structural steel. Furnace provided with high alumina refractory material for higher thermal efficiency. Conveyor controlled by variable speed drive. Freely radiating or radiant tube type heating elements designed at lower surface loading ensures longer life. Uniform temperature due to sub-divisions of furnace in to heating & soaking zones. Rapid cooling of parts through water, oil or air cooling arrangement. Require very low maintenance in long run. Component Processed: Sintered powder metallurgical parts Brazing of radiators, nozzle, pipe & other assemblies Hardening & tempering of fasteners, springs, hand tools, circlips, bearing, chain, locks, auto parts etc. Bright annealing of surgical parts, steels parts etc. Normalizing & Homogenizing of forged components.

Continuous Heat Treatment Furnace

Get Price Quote

Continuous Heat Treatment Furnace, wire annealing furnaces