Food Handling Conveyors

300,000 Per Piece

1 Piece (MOQ)

Rough Top Conveyor Belt

Get Price Quote

We are positioned amidst the prominent Rough Top Conveyor Belt Manufacturers in India. Light weight goods, fragile or deformed materials and packed goods like papers, bags, glass, boxes, cartons etc. can be easily distributed with the help of the Rough Top Conveyor Belt offered by us. Why Our Rough Top Conveyor Belt? Creates less friction coefficientPerfect for running over table and flat panelSpecial Mesh-like pattern generates the relief effectAbsorbs vibrations, preventing material slippage Construction and Properties 2 or 3-ply construction with cut edgesCarcass of synthetic EP fabricOdorless, nontoxic, non-markingTop cover : Full 1/8¨ thick SBRBack protection : Durable friction surface bottom or a synthetic barebackBlack top cover : For utility type incline serviceTan cover : For transporting packaged food products

Best Deals from Conveyors

Belt Conveyor

Get Price Quote

1 Set(s) (MOQ)

Industrial belt conveyor machine is used for grain handling as well as lime handling purpose. Conveyor is also suitable for handling sand, cement, fertilizer, box. It is useful for confectionary handling and also be used for pouch handling purpose. Belt conveyor is suitable for big capacity and long duration. It is suitable to convey, grains, cereals, rice, cement, stones, etc. It constructed with fabricated sheet, rubber belt, bearing and pillow block etc. It is used to convey the material horizontally. Available with various capacity and length as per the requirement.

Roller Bend Conveyor

Get Price Quote

100 Unit (MOQ)

Sheet Conveyor

Get Price Quote

Max. Design Speed 150Mt/Min. Simplex structure, duplex structure is optional. Lengthways conveying, manual batching, automatic stacking and transverse ejecting. Maximum stacking length: 300mm Available Width: 1200-2200mm.

Conveyors

Get Price Quote

Slat Chain Modular Conveyor Conveying Bottles, Bags, Boxes, etc. Integrated operation with filling Machine Speed Control by AC Drive 1Φ & 3Φ operation available

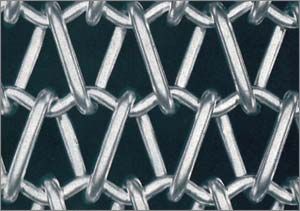

metal conveyor belts

Get Price Quote

Metal belts are made by joining a number of spiral wires with or without cross wires. It is flexible along its length, semi-rigid across its width and rigid in thickness. Each Continental Profiles belt is individually engineered to give outstanding performance and extra long life. The requirements of application, service, design of conveyor, are ideally synthesized with constructional details of belts and materials of constructions. It is a versatile product used in a wide spectrum of industries ranging from food processing to aero-space. End pressed and rod reinforced belts are ideal for sintering, copper brazing, silver soldering, bright annealing and other heat treatment operations. The special design of ends ensures trouble free performance during long-term round-the-clock operations as high temperatures. Food processing industry employs Continental Profiles belts on an extensive scale. Stainless steel balanced belts in ovens and multigrill belts for bread cooling have proved to be and ideal choice. Belts are used for slicing, washing, dewatering, cooling and wrapping for sort of food articles In plywood industry Continental Profiles bands can be seen on band dryers of Schilde, Tromag, Hildebrand and other reputed manufacturers of plywood equipment. These bands are made from specially drawn wires having flat-oval profile. The quality of wires ensures impressions-free thin veneer at the highest operating speeds. Continental Profiles balanced belts are being used in numerous glass and decorating ware factories in all phases of production e.g. I. S. machine conveyor, transfer conveyor, annealing and decorating lehrs, transportations of semi-finished and finished products packing etc. Electric lamp shells are annealed on Continental Profiles balanced belts with minimum breakage. Sprocket driven balanced belting is ideal for curing fibre glass. Continental Profiles belts are engineered to provide high tensile strength, straight travel and smooth surface for any conveying operation. Sterilizing and drying of bottles in pharmaceutical industry is ideally done on balanced belting. The belt design provides for efficient heat circulation.

Rubber Conveyor Belts

Get Price Quote

We are listed at the apex as a Rubber Conveyor Belts Supplier in India. We provide all types of Rubber Conveyor Belts for shot blasting machines and for other type of conveyor systems in various grades such as Food Grade, Heat Resistant, etc. The unmatched quality and unsurpassable performance attract various industrial sectors to place repeated orders for the Rubber Conveyor Belts from time to time. Additionally, customers are eased with the availability of the Industrial Rubber Conveyor Belts in varied sizes and dimensions. Sizes Available For Tumblast Shot Blasting 20x 27 machine 27X 36 machine 36X 42 machine As per the customers specification Type Available Airport (Baggage handling conveyors) Pharmaceutical (Medicines) Fruit Pulp processing (Food grade conveyors) etc. Salient Features Resistant to adverse conditions like heat and fire High strength Wear resistant grade Great performance Cost effective

PU And PVC Conveyor Belt

100 Per Meter

1 Meter (MOQ)

Screw Conveyor

Get Price Quote

We have voluminous warehouse that has loading docks to load and unload goods, well-maintained by the professionals. Our completely automated warehouse is sternly supervised to check that products are kept carefully. This is due to our cordial associations with the logistic companies that we are able to reach any preferred Faridabad(India) with ease, thus meeting the delivery schedule.

Magnetic Drum Separator

250,000 Per Piece

1 Piece(s) (MOQ)

Our company is bracketed among the distinguished Manufacturers, Suppliers and Exporters of Magnetic Drum Separators from Haryana. The Magnetic Drum Separators offered by us are used in all the processing industries for separation of iron from minerals, chemicals, food, floor, plastic, grain, sand ,cement, fertilizer, abrasives, glass, ores, rocks and many other products. Our Magnetic Drum Separators have an open magnetic system with the magnetic poles located in one plain. Features : Seamless performance Application specific design Highly effective separation

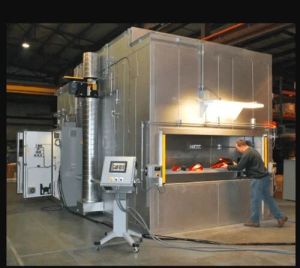

conveyorised oven

Get Price Quote

our organization is engaged in manufacturing and supplying high quality range of conveyorised oven. These conveyorised ovens are very durable, have high strength and offer great temperature control for various industrial applications. Our conveyorised oven are highly reliable and energy efficient with great capacity and stability for long lasting use. These conveyorised oven are able available to our clients in various sizes and designs depending on specifications at market leading range of prices. features excellent quality easy to control and use high capacity low maintenance energy efficient

Horizontal Screw Feeders

Get Price Quote

Horizontal Screw Feeders with Storage Bin, We are offering a wide range of precise and accurate Horizontal Screw Feeders with Storage Bin to meet the various volumetric process requirements at a controlled rate. Screw Feeders are available in various technical specifications. We are also offering custom design as specified by the client. Using quality material ensures exceptional durability and long term stability.

Industrial Ovens

Get Price Quote

Available in various designs to suit the different application, these Industrial Ovens are manufactured in confirmation to the established industrial guidelines. We are ranked among the reliable Manufacturers, Suppliers and Exporters of the Industrial Ovens located in Faridabad. These Industrial Ovens are acclaimed for their long-life. Our range of Industrial Ovens consists of Varnish Baking Oven and Paint Baking Oven. Highlights DurabilityCorrosion resistance Sturdy construction Low maintenance Types of Ovens Enhanced Duty Walk-In Ovens Bench Ovens & Cabinet Batch OvensIndustrial Aluminum Age OvensComposite Curing OvensCustom Batch OvensDrop Bottom FurnacesElevator Style Batch OvensHeat Treat Ovens & Draw and Temper Furnaces Heavy Duty Walk-In Oven Horizontal Quench FurnaceLab Ovens & IncubatorsNormal Duty Walk-In Oven Pit FurnacesPowder Coating Systems Powder Coating OvensReach-In Cabinet Batch Ovens Design Feature Robust MS shell to survive continuous operation.Specially planned, self-locking type doorHeating elements operating on low surface load for longerElements life plus nonstop trouble - free furnace operationRefractory and insulation of high quality bricks / ceramic fiber for energy conservation Heat loss prevention by asbestos rope for doorPerfect temperature uniformity in the furnace useful spaceAutomatic temperature control by digital controllerElectrical Switch Gear items of reputed make, along with controllerHoused in aesthetic control panelSafety interlocks and protection devices for safe furnace operation Area of applications : High / Low temperature Tempering, Annealing; Heat Treatment, Ceramic ware Biscuiting & Glazing Carburizing, Nitriding & many more. Chamber Sizes : Custom-built to suit customer's precise requirements. Temperature Ranges Up to 1150oCUp to 1400oC Heating Medium : Electrical / Gas / Oil

gravity conveyor rollers

Get Price Quote

We design and supply high performance gravity conveyor rollers that are ideal for bearing light to medium weight packages in either temporary or permanent installations. These are available in various materials, however the operating principle is the same. A round tube, which is generally steel, is supported on a shaft by the bearings. The shaft is contained within formed or structural punched frames either through internal springs or retaining pins. We manufacture gravity conveyor rollers in range of up to 75mm diameter and in length of 1000 mm as per the requirements of our clients. Made of centerless grinded ERW or seamless pipes, our rollers provide a very free movement. We have sealed these rollers from both sides that protect the ball bearings from dust and other particles. To prevent from rusting, the rollers have been galvanized or chrome plated. We also offer P.U. & PVC coated rollers to protect the components from damage or chemicals or wired wheels. Advantages Low speed or gravity conveyor system applications> Economical cost

Screw Conveyor

Get Price Quote

Industrial Single Deck Oven

Get Price Quote

annealing ovens

Get Price Quote

Screw Conveyors

Get Price Quote

BHP is proud to introduce its BAZER's Fine Screw Washer SW0900, packed with a host of features that make it reliable, robust and easily adjusted to a variety of tough applications in the aggregate, mining, cement and steel industries. BAZER Fine screw washer is ideally suited for removing material in application such as fines recovery, sand manufacturing, concrete reclamation, and municipal waste removal. Built with large, three stage gearboxes and outboard lower bearing assemblies, the units are designed for operating life and maintenance ease. BAZER's washing equipment is fabricated with heavy duty tubs, ensuring an operating life that will exceed that of the competition. The best feature of BAZER's washing product involves the extreme duty gearbox, designed for maximum torque, and slow speed operations. With oversize gears, these most critical components of the sand screw provide added safety for today's demanding operatorsOperating Principal Feed material enters the feed box and is distributed into the washer's setting pool. Internal and external baffles control the feed velocity and limit water current speeds and turbulence, enabling the washers to retain fines. Lighter products such as silt, excessively fine materials and other deleterious materials do not have time to settle and are carried away with the water over the long, adjustable side and end weirs. The settled material is augured up the washers by the spiral flights. Additional cleaning takes place by the abrading action of the material fractions. Excess water is drained back to the pooling area as the material is conveyed up and out the upper end of the trough.

Z Type Conveyor

Get Price Quote

We are the most reputed Exporter and Supplier of highly efficient Z Type Conveyor. These Vertical or Z-Type bucket elevators are very advanced and widely used in snacks packaging applications. This Z Type Conveyor is used to carry products in order to shift them onto the machine hopper. The speed of these Z Type Conveyors is perfectly synchronized with the main machine so as to make them work efficiently. This Z Type Conveyor is also equipped with a Vibratory Feeding System for the purpose of easy feeding of snack products into the buckets without breaking them. Features : Easy Discharge of material on to buckets with help of Vibrator based feeding system. Hopper Capacity : 50 to 100 kg Elevator is controlled by automatic level control system with leveling sensors. Available with fully covered frame in case of powder Easy to clean the bottom turf by bottom opening All material contact parts are made of stainless steel

MS Roller Conveyor

Get Price Quote

SCREW FEEDER

Get Price Quote

mild steel rollers

Get Price Quote

Belt Conveyor

Get Price Quote

We offer belt conveyor.

Annealing Tray Type Ovens

65,000 Per unit

Hot Air Oven

Get Price Quote

Sterilization is a major procedure that is used in major industries for the purpose of cleansing and elimination of any contaminant such as particulates, microorganisms, etc. The instrument utilizes the dry heat for the purpose of sterilization. Presto offers highly effective and efficient testing instruments that are used for sterilization of tools, products and materials for better quality assurance. With the help of Presto’s Hot air oven, the manufacturers can assure high quality of products delivered to the customers with the help of better sterilization process.

Conveyors

Get Price Quote

We are specialize in manufacturing & supplying of automatic Conveyors for various kinds of applications from India.

SCREW FEEDER

Get Price Quote

We are offering a wide range of precise and accurate Screw Feeders to meet the various volumetric process requirements at a controlled rate. Screw Feeders are available in various technical specifications. We are also offering custom design as specified by the client. Using quality material ensures exceptional durability and long term stability. ——– Salient Features of ——– • Screw feeding system for feeding the material into upper hopper of machine.• Suitable for all type of powders such as Spices, Milk Powder, Pesticides and other powder products.• All contact parts are made of stainless steel.• Main hopper capacity – 60 kgs – (depends upon density ofmaterial ).• Automatic material controlling in upper hopper.• Geared Motor – 1 HP & 2 HP three phase 440 V AC.

Screw Conveyor

Get Price Quote

Pan Conveyors

Get Price Quote

Pan conveyors are designed to meet your material handling requirements, convey material both horizontally and up to 60 degrees inclination. Various designs of aprons and pans are available including the AFT pan design, deep bucket conveyor design and apron pan designs to meet any application requirements. The AFT pan design incorporates precision formed overlapping steel pans with lip contact between adjacent pans and between adjacent side plates of pans. Spillage is minimized even at steep inclines or when the pans articulate over the head or tail shafts.