Zig Zag Oil Filter

These filters are made of high quality filtering medium and are used in the fuel line of passenger vehicles like Audi, Mercedes, Skoda, Volkswagen and so on. The unique design of these filters facilitates accommodation of more pleated media inside the same volume, thus increasing the filtration capacity of the filter, while maintaining high flow rate.

...more

Wire Mesh

Wire mesh and weld mesh in all sizes and profiles are available - in rolls, sheets and rolled cages. available in steel, brass, gi and all grade of stainless steel, our customers can specify the optimum design for their application.

...more

Wing Nut

These are casted nuts with two wings made for easy gripping and tightening over the Cartridge Hangers to hold the filters in the Filter Housing. They are made of graded cast iron; duly machined and Zinc plated and are supplied with Neoprene Gaskets for effective sealing. Dauji engineering can supply duly machined, zinc plated or power coating items in cast aluminium, cast iron and cast stainless steels in any size and profile. The size and profile of these casting are suited for specific filter or general requirements.

...more

un winding system

This unit comprises of a Mother coil loading and un-winding system. The mother coil is loaded pneumatically (cylinder actuated) either manually through a hand lever / foot pedal or through a solenoid valve/control panel. Un-winding, holding and release of coil is actuated through pneumatically operated Air (Expandable) Shaft and Clutch-Brake mechanism. Speed of the un-winding shaft can be controlled through AC Variable Frequency Drive and sensed through Proximity Sensors.

...more

String Wound Polypropylene Yarn Cartridge

String Wound Polypropylene Yarn Cartridge Filters are an economical solution to filter out suspended matter, sand, silt, grit and rust from water. Other than water purification, they are also used in beverage, chemical and pharmaceutical industries. These filters are made of Polypropylene strings that are wound tightly over a Polypropylene core which strengthens the cartridge. String Wound Cartridges can filter out particles from as low as 1 micron to 200 micron and are generally available in standard lengths of 10”, 20”, 30” and 40” . Standard diameters available are in 62mm (Slim) and 105mm (Jumbo). However length and diameters other than standard can also be provided on requirement.

...moresilicon rubber seal

Brand Name : Dauji

Material : Silicon

Shape : Round

Packaging Type : Carton, Packet

...more

seals and gasket

The seals and gaskets which are precision molded can be supplied in different grades of rubber and can be provided in various configurations, profiles and cross-sections. The seals and gaskets can be supplied in FDA compliant grade also on requirement. These seals/gaskets which can be pasted either on the top or the bottom surface of the End-caps or on the circumference of specially molded plastic end-caps of filters are very effective in sealing against leakage or mixing of dusty air with the clean/filtered air in the Filter/Bag Housing or Dust collector. Supply Range : Grades: Natural Rubber, Sponge Rubber, EPDM, Neoprene, Nitrile, Silicon Hardness: 20 Shore ‘A’ (minimum) to 90 Shore ‘A’ (maximum); (Standard 70 ± 5 Shore ‘A’) Service Temperature: (-) 20°C to (+) 120°C (EPDM, Neoprene, Nitrile) (-) 20°C to (+) 230°C (FDA compliant Silicone) Profile Shape: Triangular, Square, Rectangular, Round, Oval, Flat (Any special profile/configuration on request) Profile Size: Up to Φ15 (Round), 15 x 15(Triangular, Square and Rectangular) Seal Shape: Extruded continuous length Molded Ring Shape (up to Φ 400mm) Molded Square/Rectangular Shape (up to 1000mm) (Sizes beyond these on requests)

...more

Rubber Component

Dauji offers a wide range of rubber components made in neoprene, silicon, EPDM and other synthetic materials. These moulded rubber components like Washers, O- Rings, Gaskets etc. are used in the filter industry for various applications in air and gas turbines, hydraulic, fuel, lube and oil filters.

...more

Rotary Pleating Machine

Dauji rotary pleaters are customized for specific filters sizes and media and enable high speed filters pleat production of desired profiles. Pleat lock designs and dimple forming machines are available with the flexibility of easily modifying pleat depth by using rollers of various diameters.

...more

Re-Winding Machine

This is a multi station and multi shaft machine, where the slitted coils of different width are again re-winded. Speed is controlled through a AC Variable Frequency Drive and sensed through Proximity Sensors.

...more

Polypropylene Yarn Catridge Winding Machine

These are dedicated machines for winding of polypropylene yarns/threads on filter core. These machines are characterized by: High speed and output. Low energy consumption Low noise. Good yarn forming ability Variable and easy speed setting Easy adjustment of wound yarn’s degree of tension and winding pattern. Automatic stoppage on completion of winding Quick to replace yarn changing device Can make cartridge with variable length like 10”, 20”, 30”, 40” and variable diameter like 62mm, 105mm. However machine can be customized to produce other length and diameter also as per customer requirement.

...more

pleating machine

This high speed machine produces accordion pleats with dimple shaped pleat locks. These pleat locks create physical gaps in between the adjacent pleats. The machine employs two sets of Rollers- the first set is the Marking Roller which provides impression of the dimple locks and pleat folding lines on the media; the second set of Rollers pushes the media and folds the media along the folding lines to form accordion pleats.

...more

Pleated Paper Pack End Jointing Machine

This machine seals the edges of a pleat pack thermo-electro-pneumatically after PVC based adhesive is applied over the edge. After the adhesive is applied in between the two edges of the pleat pack, it is put in between the two pressing bars both of which are heated through electrical heaters. The edges get sealed when the top bar presses against it through pneumatic force. The salient features of this machine are: Movement of the top Pressing Bar is through Pneumatic Cylinders Bottom Pressing Bar is fixed and insulated to prevent heat loss. Pneumatic system is complete with all the regulating arrangements like Pressure Regulator, Pressure Gauge, Safety Valve, FRL unit with Air Release Valve etc. Provided with Pre-set Timer and Buzzer to indicate the completion of heating/pressing cycle. Provided with auto cut-off system to stop the machine on reaching the heating/pressing cycle. Provided with Digital Temperature Display and Controller. Top Plate can be retracted manually with pneumatically operated Foot Valve or it can be retracted automatically on completion of heating cycle through PLC based control system Standard table size is 650mm (L) x 600mm (W) x 800mm (H). However this size can vary based on customer requirement. Utilizes heat load of up to 3 KW.

...more

Pleat Locking Band

We can supply molded bands in plastic (ABS; Polypropylene; Nylon; HDPE , Cotton + Polyster and NOMEX in different standard widths. These bands can be used in holding or separating each pleats of the pleated cartridge of the filters from outside.

...more

Perforation & Expander Machine

A range of forming machines is available for making perfo & expanded sheets ( in paper and metal). In addition, to our standard profile range, we can customized for any special type of cage profile required.

...more

Moulded Part

Molded parts of synthetic plastic material are being increasingly used in filter industry due to environmental need and we can offer these items in accordance with customer’s needs.

...more

Metal Free Fuel Filter Element

This filter forms a integral combination of hous ing and filter element both and provides a superior protection to the diesel engine from any dirt, dust, rust, water and other contaminants that lead to the wear and tear of the fuel system and the engine. It reliably filters out particles down to 4-5 microns and attain 100% water separation with diesel fuel.

...more

Knife Pleating Machine

Manual setting of Pleat depths. Different Pleating depth range : 5 to 55mm 10 to 75mm 20 to 100mm 20 to 150mm Pleating widths : 610mm 1000mm 1250mm 1350mm 1600mm 1750mm 2000mm 2300mm 3000mm Pleating speed up to 60 pleats per minute with variable speed control. Pre-heating Post-heating arrangement. Manually controlled top post heating platform. Heating Platforms are thermally insulated. Digital Pulse Setting Countingmarking. Digital Temperature Control. Manually operated lubrication system.

...more

Hot Plate Machine

This machine is used to bind the filter media with the end cap after adhesive is poured over it. Two Hot Plates-one at the top and the other at the bottom press the assembly electro-pneumatically and the adhesive gets bonded to the end cap/filter media and support tube due to heat. The salient features of this Hot Plate are Movement of the top Hot Plate is through Pneumatic Cylinders Bottom Hot Plate is fixed and insulated to prevent heat loss. Pneumatic system is complete with all the regulating arrangements like Pressure Regulator, Pressure Gauge, Safety Valve, FRL unit with Air Release Valve etc. Provided with Pre-set Timer and Buzzer to indicate the completion of heating cycle. Provided with auto cut-off system to stop the machine on reaching the heating cycle. Provided with Digital Temperature Display and Controller. Top Plate can retract automatically on completion of heating cycle through PLC based control system Standard table size is 500mm (L) x 600mm (W) x 750mm (H). However this size can vary based on customer requirement. Utilizes heat load of up to 6 KW.

...more

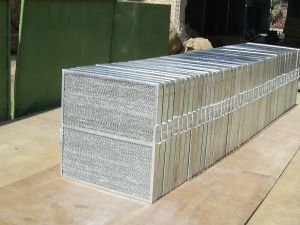

High Velocity Panel Filter

This high velocity panel filter consists of a find zinc electroplated wire mesh screen of aluminium, St. Steel or bronge in herringbone crimp and stainless steel or galvanised frame. The unique arrangement of the screens allow dirt to be loaded progressively through the media and not just on the face of the media. and it is easy to clean this type of filter with a stream of a water. The filters are available in a variety of frame sizes & varying mesh sizes.

...more

Filter Pleating Machine

Dauji engineering design and supplies a complete range of pleating machinery for manufacturing of air, dust, oil & water filters. A suitably designed for a variety of filter media and different pleat configurations, we have a machine to suit every challenging application. All pleating machines are available alongwith a variety of options and accessories. Machines are available in manual, semi manual or fully automatic constructions. Features provided are customized to customer preference.

...more

FILTER PAPER COATING PLANT

The Coating Unit provides strength to the filter paper media by bonding it with resin and providing corrugations over it. In the Coating Unit, the filter media is processed and fed gradually through following four stations: Unwinding and Coating Station Unwinding station houses 02(two) numbers of loading/un-loading shaft to hold paper reels• Motion of the un-loading shafts controlled through mechanical clutch system.• Un-wound filter paper passes through a series of Hard-Chrome Plated Rollers (driven through chain-sprocket synchronized drive) before passing through Chemical Coating Tank (M.O.C-Stainless Steel).• The filter paper gets coated when it passes through a series of Tension Rollers (rubberized) and kisses over a Phenol Resin Coating Roller (dipped in the coating tank).• The motion of the Coating Roller is controlled with AC motor and Variable Frequency Drive.• Resin & PVA Methanol Mixing Drums ( 02 numbers of 200 litres capacity) are provided along with gear motor drive. Station-2) Drum type Paper Drying Station• Coated paper gets dried-up after it passes through a series of heated drums.• Diameter of Drier Drum = 500mm• Width of Paper Drying Drum = 1000 / 1250 / 1600mm / Custom Made• Drums heated through electrical heater coils.• System provided with Digital Temperature Controller and ‘Auto-Cut-Off’ system.• The external surfaces of the drums are hard chrome plated. Station-3) Paper Corrugation and Marking Station• The dried paper gets corrugated after it passes through a set of Corrugation Rollers.• Diameter of Corrugation Rollers = 250mm• Width of the Paper Corrugating Rollers = 1000 / 1250 / 1600mm / Custom Made.• Corrugated Paper gets marked on the coated side through Line Marking Reels dipped in an Ink Tray (M.O.C.-Stainless Steel).• Motion of the Marking Reels controlled through mechanical clutch system. Station-4) Paper (coated & corrugated) Re-winding Station• Coated paper is re-winded on a single shaft Re-winding Station.• Width of Re-winding Unit = 1000 / 1250 / 1600mm / Custom Made.• Motion of the Re-winding shaft is controlled through mechanical clutch system.• Motion is provide with AC motor with Variable Frequency synchronized drive.

...more

Filter Paper Burst Testing Machine

This machine is used to test the bursting strength of the Filter Paper / Element Test Paper (Filter Element) is put on a Holding Station and clamped from the top. From the bottom of the Holding Station, a Diaphragm is pressurized which presses against the Test Paper / Filter Element. The Diaphragm is pressurized by Glycerin filled in a container which is pushed by a moving Piston actuated mechanically. The load at which the paper fails(bursts) against the expanding Diaphragm is noted through Double Needle Manual Dial gauge.

...more

Filter Flanges

We provide a comprehensive range of filter end-caps to suit a very wide variety of standard and non-standard filters. End Caps with unusual profile are our specialty, which can be used in different application areas. For custom End-caps, we specialize in quickly developing Dies/Press Tools and Moulds for End Caps of any unusual and non-standard profiles specific to any particular customer requirement /application areas

Type : Filter Accessories

Material : Aluminium, Brass, G.I, Metal, Mild Steel, Plastic, Stainless Steel, Food Grade- Abs

Shape : Rectangular, Round, Square, conocal

Thickness : 0-50cm

Application : Air Filtration, Gas Filtration, Oil Filtration, Water Filtration

Condition : New, Fresh

Dimension : Customs

After-Sales Service Provided : Yes

...moreBe first to Rate

Rate ThisOpening Hours