Sand Blasting Machine

Get Price Quote

Being an established brand in the industry we are offering Sand Blasting Machine to our valued clients. The product we offer is excellent in quality, as it is manufactured by using the excellent quality materials along with the latest technology. The product is designed for precision and excellence by our experienced team of professionals. Our product is highly demanded, as it is used for various applications like cleaning of molds, putting grains on the molds, preparing the surface for painting, coating, and much more. We are offering this machine at a very marketable rate. Portable Abrasive Blaster The portable abrasive blaster are safe, high productivity systems designed for use with a wide range of abrasive media. The operation is performed on metals, glass, ceramics, plastic and stone. The machine works on pressure blasting principle, consist of a blast generator. The abrasives are filled at the top of machine when machine is not working and blast generator is not pressurized. At the top, a vibrating sieve is provided to sieve the abrasive filled. The oversize abrasive and debris are retained on the screen, thus prevent the choking of blast line. When mushroom valve is opened the abrasive will get transferred to blast generator for blasting. The mushroom valve gets closed when compressed air is switched on and abrasive storage tank gets pressurized, for free fall of abrasive into the mixing tube. From mixing tube the abrasive is carried away by compressed air to the nozzle for blasting. The Blast Generator is fabricated from MS Steel plate of thickness not less than 6 mm as per IS-2825 and hydraulically tested for 250 psi.

Ro Water Plant

Get Price Quote

1 Piece (MOQ)

Best Deals from Filling Line

Automatic High Speed Candy Pillow Packing Machine

325,000 - 425,000 Per Piece

1 Piece (MOQ)

Single Chamber Tea Bag Packing Machine

Get Price Quote

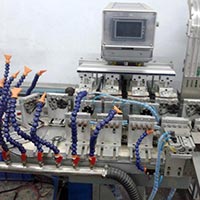

1-2 Color Beverage Caps Printing Machine

Get Price Quote

1 Piece(s) (MOQ)

We offer 1-2 color beverage caps printing machine. • model no.:rpm-2c-cap • plate size:100*200mm • printing area:φ28-30mm top of caps • print model: • printing color:1 color (with speed 21600pcs each hour) 2 color(with speed 10800pcs each hour) • products size:φ28-30mm caps • speed:900cyclehour=900*8*2=14000pcshour 22color • power:single-phase 220v 5060hz 7kw • air source:6bar • machine size:1800*1220*2000mm • weight:320kg • delivery time: 60 days once get the deposit.

Air Intake Manifold

Get Price Quote

We offer Air Intake Manifold that is heavily demanded for automotive applications. With a precision design and accurately made intake runner surface, our air intake manifold is ideal for reduction of turbulence that affects the speed and efficiency of the engine.

form fill seal machines

Get Price Quote

Paste Packing Machine

Get Price Quote

We are offering liquids and pastes packing machine. Provision for two rolls on unwind sealers are both end supported end roll detection synchronized with plc & filling provision for batch cutting & counting temperature control and heater failure indication is through plc hence, eliminating the need for temperature controller paper break detection sensor joint detection sensor (optional) hopper level controller

Powder Filling Machine

Get Price Quote

pick fill seal machine

550,000 - 750,000 Per unit

Pick ,fill and Sealing Machine with weight filler for filling & sealing of preformed pouches of snack foods , dry fruits, Seeds, Chips, Mixtures etc. The machine works automatically in picking, filling and sealing of pouches. It offers flexibility of using pouches in different forms such as stand-up pouches, pouches with spouts, zippers and many more.

Automatic Cashew Nut Filling

Get Price Quote

Pillow Machine

Get Price Quote

The horizontal pillow wrapping machines can wrap all kind of commodities such as Biscuits, Candies, Wafers, Chocolate, Bars, Chewing gums, Soaps, Instant Noodles, Dry cells, Facial paper, Crackers and any other rectangular, square, round or irregular shaped products. Suitability to pack variety of solid Shapes & Material. Capacity to pack variety of sizes with high speed & safety. Pouch cut-off length can be calibrated by hand wheel. All contact parts are made of stainless steel. With design registration system.

Collar Type Auger Filling Machine

Get Price Quote

Koyka Electronics Pvt Ltd is recognized as a dependable Exporter and Supplier of Collar Type Auger Filling Machine. We specialize in offering two variants of Collar Type Auger Filling Machine i.e. Collar Type Auger Based Filler and Collar type Cup Filler. The users can productively and cost effective pack the Sachets, Bags, and Pouches. These are pneumatic type auger filler machine.Applications Spices Powder Food Beverage Commodity Ice Cream Powder Chemical Coffee Powder Milk Powder Medical

Multi Head Weigher

Get Price Quote

UNITECH offer first rate Multi Head Weigher which is load cell based and find their utility in all the relevant industries. The raw materials that are used are resourced from certified vendors. Our range of multi weigher is popular among our esteemed clients for the features including operator friendly, increased shelf life, easy lubrication system among others. Our range of multi weighed includes collar multi weigher, pneumatic collar machine and pneumatic FFS machine. We are offering pneumatic collar machine. These pneumatic collar machines are a robust machine with particular consideration for minimum maintenance and ease of adjusting and giving high reliable output. All parts in contact with product, manufactured in stainless steel. Accurate sealing die temperature control and fully controllable die pressure. Cut off blades for separating sachet from film web housed in horizontal die for maximum efficiency. Photo cell print registration. Comprehensive push button control panel with cycle counter. Front safety guard and access door electrically interlocked (Optional). Tool kit and Operator Manual supplied with the machine Product Range Rice, pulses, tea, coffee beans, candies / toffees, tablets, cashews, potato / banana wafers, snack foods, fresh & frozen foods, dried fruits, pasta pieces, detergents, hardware items, spices, soup mixes and sugar. Filling Range For IPM-901/MW : 10 grams to 500 gramsFor IPM-901/MW: 10 grams to 3000 gramsOutput Up to - 50 Packs / minute, Dependent on product type and flow propertiesPack Size For IPM 901/MWFor IPM 901/MWWidth in mm 40 to 175 50 to 250Length in mm 70 to 250 70 to 500Filling System 2 to 12 Head computerized combination weigher with following features Completely micro-processor controlled for easy set-up and operationStepper motor drives for all actuators & no Pneumatics is neededSuperior accuracy with high speed operationUser friendly colour touch screen controlsSelf-diagnosticQuick access to all parts for cleaning and maintenance. No tools required Statistical data available on screen or via optional printer outputStainless steel contact parts throughout. IP 65 ratedMachine setting can be simply programmed and stored in the machine memory to allow for different product weights, as well as products with different feeding characteristics.Weighing accuracy 0.4 to 1.0 gramProduct codes up to 99 The IPM - 901 machines can be fitted with any one of the following fillers.Stepper motor drives control both the intermediate and weighing buckets, which can be custom-set for the desired speed and product volume. 12 Head Combination weigher can be given as an option. Special Features Servo driven draw down beltsServo Motor driven high speed sealing JawsPLC control with HMIPneumatic actuated draw down belts, driven by Servo MotorDetachable Perspex and stainless steel guards. Easy for fault finding.Can be adapted to seal unsupported films using impulse sealing systemIn-built self-diagnostic featuresHourly production dataOverload protectionP.C. Uplink facility (Optional)Password protection setting Packaging Materials The machine will accept most types of laminated films up to maximum of 500 gauges (125 micron). It is important that the sealing medium incorporates the best possible slip characteristics. Pure unsupported polythene film may be used with special impulse sealing equipment. Electrical: Power Input for bagging machine 3 phase 415 V AC, 50 Hz3.4 KW Compressed Air Pressure 6.0 kg/cm2 gFor IPM 901/MWFor IPM 901/MW Floor area with weigher stand in mm 2400X2400 & 2400X2400 Height with 10 / 12 Head Weigher in mm Power Input for Multi-head weigher 220 + 5 V AC, 50 Hz, & 1.5 KVA Dimensions & Weight 2800 & 3200 Net weight in kgs 1000 & 1200 Power Input for Multi-head weigher : 220 + 5 V AC, 50 Hz, 1.5 KVA Dimensions & Weight : 28003200 Net weight in kgs : 10001200 Take-off Conveyors, In-Feed Product Elevator system, Batching device, Tear-cut devise, Perforator between sachets, Coding, Over-printing attachment, Gas. NOTE : Description and Specification of the machine are subject to change without prior notice.

Sewage Treatment Plant

Get Price Quote

Sewage treatment plant Water treatment plant Oil and grease trep Effluent treatment plant Air pollution control plant

Pyramid Tea Bag Packing Machine

Get Price Quote

We are successfully ranked amongst the top traders and suppliers of Pyramid Tea Bag Packing Machine

Multihead Weigher Large Vertical F.F.S.

Get Price Quote

The versatile and modern large vertical FFS with multi-head weigher is suitable for all your packing and weighing needs. The machine runs smoothly over extended periods of operation and provides greater returns on your investment. Features Right, Quick, Not break material. High standard, high efficiency, reduce cost. Adapt to the packing of high and delicate product

Capping Machine

Get Price Quote

Utilizes heavy duty self lubricated and enclosed indexer for the turret movement. A single three-phase motor and gearbox drives the full machine. VFD for variable speed drives the motor. An adjustable torque non-contact magnetic clutch is provided for long life without wear and tear. The cap tightening chuck needs to be changed when cap changes. The chuck changing is very easy and quick. All the electrical is mounted in the control panel. The control console is ergonomically placed for convenient operation The machine is provided with adjustable SS legs for leveling the machine in line with other machines. (Depending on Can and cap sizes and shapes.) Can diameter: – 35mm to 80mm. Can Height: – 20mm to 60mm. Cap diameter –20 to 45mm with suitable change parts.. Power requirement:- 0.75KW

cosmetic packaging machine

Get Price Quote

bag packing machine

Get Price Quote

5-50kg bag packing machine, that fills on the basis of weight. Empty bag is clamped in the machine. The material is weighed and then discharged in the bag. Once the bag is released from the machine it falls on the optional conveyor which takes it to the stitching head where the mouth of the bag is stitched and it then falls out of the machine. This machine is ideal for 10kg, 25kg Rice Bags. Applications Rice Grains Fertilizers Granular free flowing Products Sugar, etc.

bottle cap making machine

Get Price Quote

Pioneers in the industry, we offer aluminium bottle cap foil sealing machine, aluminium foil sealing machine, hand sealer, heavy gear horizontal band sealer machine with emerge stop, teflon belt for band sealer machine and pouch packing hand sealer machine 8 inch from India.

Swimming Pool Water Treatment Plant

Get Price Quote

Implementing the latest engineering technology, we bring forth Swimming Pool Water Treatment Plant of highly efficient type. The Swimming Pool Water Filtration Plant is fabricated in a manner which ensures uninterrupted flow ability to provide highly-pure water filtration. The Swimming Pool Water Treatment Plant has been frequently used in the swimming pools, amusement parks, hotels, resorts etc. with confidence. Among the Manufacturers of Swimming Pool Treatment Plant, our name is taken with respect for maintaining consistency in quality. Features Completely safe water, no harm even after galloping Total destruction of micro organisms Chlorine as well as ozone based purification Powerful and faster disinfection Complete destruction of pollutants, micro-organisms, colour, etc.

LIQUID PASTE Machine

Get Price Quote

Powder Filling Machine

Get Price Quote

We are offering powder filling machine. Rollatainers offer fully automatic servo driven pouch packing machine to fill powder in pouches like spices, milk powder, detergent powder, pharma powder etc.

spices filling machine

Get Price Quote

Since time immemorial, spices have played the role as food as well as medicine. Spices bring out the unique natural taste of cuisines, are used to change the look of the food and make it look attractive. In other words, they are regarded as food enhancers as they are used to give a strong taste and an aromatic scent in cuisines. This taste, aroma and freshness are only possible when the spices are packed hygienically keeping the quality factors in mind. Flexo Pack offers a range of spices packing machine which is fabricated using quality parts to make sure they are dimensionally accurate, durable and made of corrosive resistant material. The best part is that they are offered at a transparent deal and the first preference among clients. This is because the machine has a sturdy body, highly efficient and easy-to-use.

Sand Blasting Machine

250,000 Per Units

Sand Blasting Machine

44,000 Per Piece

automatic jar filling machine with foil seal attachment

Get Price Quote

1 no Set(s) (MOQ)

We are offering fully automatic jat filling machine with foil seal attachment to pack liquids(like ghee), powders and granules.

etp plant

Get Price Quote

etp plant, Stp Plant

Gravity Filling Machine

Get Price Quote

We are specialize in manufacturing & supplying of Gravity Filling Machine for various kinds of applications from India.