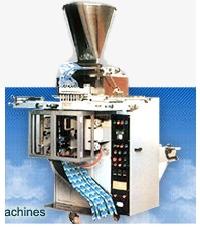

Automatic Form Fill and Seal Machine

Get Price Quote

We are manufacturing and supplying Automatic Form Fill and Seal Machines in India. Our range of Automatic Form Fill and Seal Machine is inclusive of Fill and Seal (FFS) Machines - RKPI-201-A. Our Automatic Form Fill and Seal Machine can work using any type of heat sealable laminated film. Automatic Form Fill and Seal Machine is used for packaging tablets, granules, tea, coffee, turmeric, chili and glucose, etc. Procduct Code : RKPI-201-A

Milk Chilling Plant

Get Price Quote

Best Deals from Filling Machine

Bouffant Cap Making Machine

1,300,000 Per unit

Ro Plant

Get Price Quote

100 Kilogram (MOQ)

We are noted Manufacturer and Supplier of RO Plant in India. RO Plant operates on the principle of osmosis. If two systems filled with solutions of different concentrations are connected through a semi-permeable media, the solution with lower concentration will travel to the concentrate solution. This natural phenomenon is known as Osmosis. If pressure greater than the natural osmotic pressure is applied on the system mentioned above the pure water from the concentrate solution will traverse to the lean solution leaving behind a heavier concentrate of salts. This process is applied to in the RO Plant. The durability of our RO Plant is one of its key strength. Highlights : Durable Quality- tested Energy efficient Low maintenance

Air Intake Manifold

Get Price Quote

We offer Air Intake Manifold that is heavily demanded for automotive applications. With a precision design and accurately made intake runner surface, our air intake manifold is ideal for reduction of turbulence that affects the speed and efficiency of the engine.

eps filling gun

3,200 Per Piece

10 Piece (MOQ)

EPS moulds play a vital role in the manufacturing of EPS products, offering versatility, efficiency, and sustainability. The ability to create complex shapes, coupled with streamlined production cycles, makes EPS moulds a valuable asset for various industries. With ongoing advancements in technology and design, EPS moulds continue to evolve, further enhancing the capabilities and possibilities of EPS manufacturing. As a result, EPS products will continue to be at the forefront of innovation, meeting the diverse needs of industries while promoting a greener and more sustainable future.EPS moulds are specifically designed tools used in the production of EPS products. They are typically made from high-quality aluminum or steel, ensuring durability and precision during the manufacturing process. The moulds consist of two parts: the male part, known as the core, and the female part, called the cavity. These parts fit together to create a hollow space that defines the final shape of the EPS product.Benefits of teflon coating mould: Nonstick Properties: Teflon coating is famous for its exceptional nonstick properties. It creates a smooth and low-friction surface that prevents sticking of various substances, such as food, adhesives, chemicals, and more. This property is especially useful in cookware, where it allows for easy food release, reduced need for oils or fats, and effortless cleaning. Heat Resistance: Teflon coatings have excellent heat resistance, making them suitable for high-temperature applications. They can withstand temperatures up to 260°C (500°F) without degrading, making them ideal for use in ovens, grills, and other cooking appliances. The heat resistance of Teflon coatings ensures durability and longevity even under extreme temperature conditions. Chemical Resistance: Teflon coatings exhibit exceptional resistance to chemicals, acids, solvents, and corrosive substances. This property makes them highly valuable in industrial settings where materials come into contact with aggressive chemicals. Teflon coatings provide a protective barrier that prevents chemical attacks, corrosion, and degradation of the underlying substrate. Water and Oil Repellency: Teflon coatings offer hydrophobic and oleophobic properties, meaning they repel water and oil. This feature is useful in applications where the prevention of liquid absorption or adhesion is required. Teflon-coated surfaces remain unaffected by water, oils, and other liquids, reducing staining, facilitating easy cleanup, and preventing surface damage. Electrical Insulation: Teflon coatings are excellent electrical insulators. They possess high dielectric strength and low surface energy, making them resistant to electrical current and minimizing the risk of electrical short circuits or malfunctions. Teflon coatings are commonly used in electrical components, wiring, and circuit boards to provide insulation and protect against electrical hazards. Abrasion Resistance: Teflon coatings offer exceptional abrasion resistance, providing protection against wear and tear. They can withstand friction, impacts, and mechanical stress, ensuring the longevity and durability of coated surfaces. This property is particularly beneficial in industrial applications where components are subjected to heavy use or abrasive environments. Easy Cleaning and Maintenance: Teflon-coated surfaces are easy to clean and maintain due to their nonstick and stain-resistant properties. Most substances can be easily wiped off the smooth Teflon surface, reducing the need for harsh cleaning chemicals or vigorous scrubbing. This feature is advantageous in various industries, including food processing, automotive, and manufacturing, where cleanliness and efficiency are paramount.

Semi Automatic Servo Auger Filler Machine

105,000 Per Piece

1 Piece (MOQ)

Semi Automatic Collar Type Form Filling And Sealing Machine

Get Price Quote

Thanks to our modern transit facility, that ensures safe delivery of the orders at required destinations. We are a focused towards bringing forth exceptional array of products that are quality tested from the initial stages of manufacturing. Our quality inspectors inspect each and every element of the raw material with complete proficiencyFeatures : This machine can be synchronized with dozing systems like gravimetric filling system and volumetric filling system like electronic load cell based weigh filling system, volumetric cup filling system, auger filling system etc Suitable for a wide range of heat salable film as a packing material such as pet/poly or pet/metpet/poly and laminates with aluminum foil and bopp etc Can also be provided with impulse sealing system for heat-sealable non-laminated film This machine is a versatile machine and change over of the parts for one pouch size to another can easily be done All product contect parts are made up of food grade stainless steel 55-304/55-316 An automatic pouch length change system and can be adjusted from 65mm to 270mm Various optional attachments can be provided like ink coding unit, hot foil coding unit, batch cutting unit and counter as per the customer's requirement (at an extra cost)

snack food machine

Get Price Quote

Cup Filling Single Track Machine

Get Price Quote

EPS Block Filling Gun

2,000 Per metric ton

1 Set (MOQ)

MAYONNAISE SACHET PACKING MACHINE

Get Price Quote

Paste Packing Machine

Get Price Quote

We are offering liquids and pastes packing machine. Provision for two rolls on unwind sealers are both end supported end roll detection synchronized with plc & filling provision for batch cutting & counting temperature control and heater failure indication is through plc hence, eliminating the need for temperature controller paper break detection sensor joint detection sensor (optional) hopper level controller

collar machine auger filler

Get Price Quote

The Collar Type Machine Auger Filler, which we deliver, are acclaimed for their superior make. We source only qualitative raw material from the reliable places only. Our professionals conduct strict quality checks as a result of which, finished products stand high on the clients' expectations. As one of the leading Suppliers, we keep our quality in synchronization with our reputation and offer the best Collar Type Machine Auger Filler to the buyers.

form fill sealing machines

Get Price Quote

Sealing type - centre sealthree side sealfour side seal packing range - upto 250 gms powder granules. packing speed - up to 80 pouchesmin (depends upon weight & characteristics of the product to be packed) power required - 220 vac, single phase, 50 hz. , 3 kw optional attachments - (1) hot foil batch coding (2) electronic ink coding filling systems - (1) volumetric cup filler (2) auger filler (clutch brake servo control) (3) reciprocating pump for liquid

MANUAL FILLER

Get Price Quote

single track form fill machine

Get Price Quote

We are offering single track form fill & seal machine, offered by us, is provided with model no. - (if-220). Our single track form fill & seal machine is a fully automatic single track vffs machine that is perfect for packing powder and granule products packing such as soya powder, milk powder, coffee powder, confectionery, pulses, spices, sugar, tea etc. We make sure that our single track form fill & seal machine is suitable to pack up to 100 gm of material. speed : 30-60 pouchesminute

automatic bottling machine

Get Price Quote

We are the main supplier of this product.

HTPS 1500 multitrack fully automatic form fill seal machine

Get Price Quote

Fully Automatic Form Fill Seal Machine (Multitrack We have carved a niche as the most prominent multitrack fully automatic form fill seal machine manufacturer in India. The fully automatic form fill seal machine we manufacture has the capability to pack various products of different sizes and volumes. Our fully automatic form fill seal machine encompasses both superior quality and excellent performance. The range of fully automatic form fill seal machine we proffer is in high demand due to its high reliability and long lasting life. You can avail our fully automatic form fill seal machine at very convenient prices and within stipulated time frame. Model HTPS 1500 Salient Features : The multi track form filling sealing machine is a PLC controlled fully automatic machine. One of the biggest feature of this filling sealing machine being the machine having the technology of making sachets/ pouches being an innovation of its kind in the entire nation especially designed for liquid packing thereby giving a cutting edge on the economy of the pack leading to approx. 25% saving on laminate. The machinery is capable of packing different kinds of liquids, pastes, granules, powders categorized as shampoo, ketchup, oil, lube, petroleum jelly (cream), spices, pan masala, tea coffee, liquor and other related products. The machinery also has the feature of providing on line zipper facility. Various types of heat sellable laminated films namely polyester poly, polyester metallised polyester poly, aluminium foil based can be run on the machine. The machine is further equipped with PID (proportional integral derivative) based temperature controllers. Machinery also has the feature of providing spout arrangements. There are three different models available depending ont heir roll widths viz-a-viz 400 mm, 600 mm and 800 mm. Jacket hopper with heating element for special food products namely catchup, cheese, jam can be provided as an optional device. All product contact parts are made of food grade stainless steel SS. As an optional device collating system can also be provided in the machinery.

Multi Track Filling Machine

Get Price Quote

We are engaged in offering a wide variety of Multi Track Filling Machine to our valued clients. Our range of Multi Track Filling Machine includes Semi Pneumatic Auger Based Filling Machines, Collar Type Filling Machines and Semi Pneumatic Cup Filler. These Multi Track Filling Machines are widely demanded in various industries due to their effective usage. We ensure prompt delivery of the order. Thus, we are considered as the reliable Exporter and Supplier of the Multi Track Filling Machine. Highlights : This machine is equipped with the AC frequency drive with the latest addition for speed adjustment All contact parts are made of stainless steel 316 Simple operation and low maintenance Top quality components and best workmanship Custom made to suit specific requirements Photoelectric mark registration system for precise cutting and sealing of the sachets/pouches Specifications : Packing Range : 2ml to 50ml ( 2gm to 50gm) Filling System : Piston Filler, Cup Filler Type of Sealing : Four Side Seal Packing Material : Shampoo, Oil, Honey, Ketchup, Tea, Free Flow Powder Film Size : 400mm-900mm width x 50mm-150mm length Film Roll Size : OD 250 to 400mm max. ID film reel pipe 75mm min Film Roll Type : Laminated film in roll supported film e.g. aluminum foil PE, PP Speed : 50 to 100 Stock Per Minute (varies with the nature of product & filling range) Power : 4 KW 440V/AC/Three Phase Optional : Batch Coding Device, Batch Cutting Device Auto Lubrication, GMP Model, Gas Flushing Unit Level Sensor Machine Size : 2200mm x170omm x 2300mm Weight : 1500kgs (approx)

Multihead Weigher Large Vertical F.F.S.

Get Price Quote

The versatile and modern large vertical FFS with multi-head weigher is suitable for all your packing and weighing needs. The machine runs smoothly over extended periods of operation and provides greater returns on your investment. Features Right, Quick, Not break material. High standard, high efficiency, reduce cost. Adapt to the packing of high and delicate product

servo auger filler

Get Price Quote

SERVO RELIABILITY: The auger is operated by a high performance, brushless servo motor. This servo motor provides precise, controlled, movement of the auger to dispense the desired amount of product. The Model: SI-706- Servo Auger Filling Machine is the latest development from Siddhi International. The innovative design and improved (Optional) PLC-based controls make it affordable, reliable, auger filler with the same rugged construction and dependable service.

toffee pillow packing machine

Get Price Quote

toffee pillow packing machine, stick pillow packaging machine

Packaging Machine

Get Price Quote

Automatic High Speed Bitumen Drum Filling System

Get Price Quote

The first company in India to develop & manufacture Fully Automatic High Speed Electronic Bitumen Drum Filling Automatic Bitumen Drum Filling Equipment INSTALLED AT ALL MAJOR REFINERIES OF INDIA CONTROLLED THROUGH PROGRAMMABLE LOGIC CONTROLLERS (PLC) WITH ALL THE SOFTWARE DEVELOPED IN-HOUSE ROBUST DESIGN FOR HAZARDOUS ENVIRONMENT PROGRAMMABLE FEATURES AS REQUIRED NET WEIGHT FILLING AIR FAIL SAFE POWER FAIL SAFE PROPORTIONAL CONTROL TECHNOLOGY BY ELECTRO-PNEUMATIC POSITIONER PNEUMATIC :- HIGH TEMPERATURE RESISTANT CONTROLS PROGRAMMABLE:- TOUCH SCREEN MIS FACILITY :- LAN PROVIDED (OPTIONAL) AUTO / MANUAL FILLING PROVISION

Pneumatic Cup Filling Machine

Get Price Quote

In order to keep pace with the clients’ requirements, we manufacture and supply a wide array of Pneumatic Cup Filling Machine. It is widely demanded by the packaging industry for packing tea leaves, namkeen, seeds, rice, pulses, etc. Pneumatic Cup Filling Machine is offered by us in different dimensions and specifications. Pneumatic Cup Filling Machine is available at industry leading prices.

Volumteric Cup Filler Machine

Get Price Quote

Cup Filler Machine is used to pack granular and powder items by volume. This machine has volumetric cups in which the material is filled from the top hopper. The volume of the cup is adjusted in a manner by the adjusting nut that the volume of the material in the cup can be adjusted and the final desired weight of material can be achieved. As this is a volumetric cup filler the end accuracy in net weight depends on the consistency in bulk density of the material being packed. The volume of the cups can be maintained consistently by a rigid construction of the disc of the cup filling machine, however if the bulk density of the material is varying then the net weight also varies. Another very important aspect of this machine is the flow characteristic of the material being packed. If the material does not have good flow characteristics then it poses two problems either the volumetric cups do not get filled completely or they may not get emptied completely, in both the cases there is a variation in the net weight of the pouch.It is ideal to use a cup filler where the weight variation is not a very high concern specially in products which are relatively cheap, also where the product has a good flow characteristic and high production speeds are required with a lower equipment cost. Cup filler machine is also easy to setup and involves more of mechanical parts and is easy to maintain. Our machine comes with double motors one for the rotation of disc and the other for the pulling of the laminate is recommended for a better control as both these motors have independent drives and sensors for motion they can be easily setup. The horizontal and vertical sealing are both done pneumatically. This ensures that the sealing is done properly and the temperature control is by PDI temperature controllers. Having a consistent temperature for sealing is critical to the quality of seal which ultimately affects the shelf life of the pouch. The machine comes with a camera for sensing the location of the eye mark. The batch coder prints the date code, mrp, lot code at the relevant location on the pouch.

automatic powder filling and packing machine

Get Price Quote

Form Fill & Seal Machine

Get Price Quote

Avail from us a large gamut of qualitative form fill seal machine, which is manufactured from the genuine quality raw materials. We have carved a niche as one of the major automatic form fill seal machine suppliers, based in India. These vertical form fill seal machine are perfect for the packing of liquid, powder and granules. We provide these machines with servo pulling for quick change over, variable pouch width & length, notching provision, embossing etc. as per the client�s requirement. Machine is provided with automatic temperature controller and can seal all heat sealable laminates. Form fill seal machine can produce 3 Side & 4 Side seal both plane & bottleneck and center seal pouch. Automatic Collertype Form Fill & Seal Machine Optional Features : Servo pulling for quick change over Pouch Width & Length variable, notching provision, embossing etc Automatic Form Fill & Seal Single Track Machine Optional Features : Servo pulling for quick change over Pouch Width & Length variable, notching provision, embossing etc. Features : Complete S.S. Clading Stoving PU Paint Machine can produce 3 Side & 4 Side seal both plane & bottleneck and center seal pouch. Photocell ensures the correct length of the pouch. Machine can seal all heat Sealable laminates. Machine is provided with Automatic Temperature Controller. SS Rollers and SS Reel Shaft Adjustable disc for weight adjustment. Dust Collector - Optional

LIQUID PASTE Machine

Get Price Quote