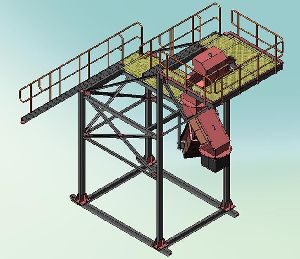

Wagon Tippler

Frigate offers a wide range of wagon tipplers including side discharge tipplers and rotary tipplers for railway wagons. The tipplers can handle wagons of various widths, heights and lengths. Side discharge tipplers are available with both mechanical and hydraulic tippling drive. Rotary tipplers unload the wagons turning through 180 degrees. A hydraulic holding system secures the wagons during the tippling process. Six clamps holding systems ensure positive clamping inspite of irregularities of the wagon surface. Frigate also offers a hydraulically operated side arm charger with positive rack and pinion mechanism. This proven design ensures accurate positioning of the wagon. A new generation side discharge type wagon tipplers (fulfilling new RDSO requirement) and side arm charger with upto 60T pull for pulling full rake of 58 wagons, can also be offered

...more

Tripper Conveyor

Like the name implies, a tripper conveyor is used to “trip” the material off the conveyor at locations between the terminal pulleys. A tripper can either be fixed position or movable and consists of a structure with two pulley assemblies. As the belt passes over the upper pulley, the material is discharged from the belt into a collection chute. The material is then diverted to one side or both sides of the belt for discharge, or back onto the belt if the desired discharge position is at the end of the conveyor. Several powered drive options and chute configurations are available for any belt tripper.

...more

static classifier

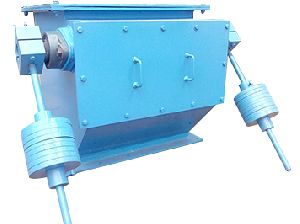

Slide Gate

The Slide Gate is an isolation device and can be supplied in low leak and zero leak designs. The low leak design is primarily used when a small amount of flue gas leakage past the closed gate can be tolerated. Typical leakage can vary from a few percent to less than one percent of flow depending on the type of seal system provided. The zero leak design is used when zero flue gas leakage past the closed slide gate is required. Zero leakage is achieved by pressurizing the seal chamber located around periphery of the closed blade with seal air.

...more

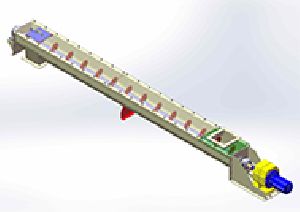

Screw Conveyor

Frigate is a reputed name for supply of large Screw Conveyors and is in a leading position for many applications. Over the years Screw Conveyors for specific purposes have been developed. Heavy- duty Cement Screw Conveyors, as used in the concrete industry, are particularly robust and equipped with self-adjusting stuffing boxes. Extra-heavy-duty Screw Conveyors, designed for continuous operation in cement, lime and gypsum processing, come with flanged shaft couplings for easy screw replacement. Difficult materials with a high moisture content that have a tendency to stick to the centre pipe or flight in traditional screw conveyors, such as sludge or screenings, are successfully handled by Shaftless Screw or Spiral Conveyors with ultra-heavy-duty helicoid flighting. The expertise that has been acquired over the years has enabled Frigate to apply their technology to virtually all conveying processes. It also has resulted in high-quality yet competitively priced Screw Conveyors.

...more

Scraper Reclaimers

A side scraper reclaimer travels alongside a stockpile on two rails with a rail gauge measuring anywhere from 3m to 5m, supported by travel bogies with a three-point system.

...more

Rotary Screen

Features : Robust, High performance, Reliable

Rod Gate

Rod gate is generally provided above an apron feeder for controlling the material feed rate. The rod gate has sturdy and rugged construction and is designed to withstand impact load resulting from large sized lumps falling from the storage silo, above.

...more

rack & pinion gate

Our Rack & Pinion gates are designed to be used in an application in which the flow of materials needs to be shut off, and then restored later. Machined rack & pinion gears allow for easier operation. Nylon rollers are used because they reduce the risk of sparking and they are resistant to rust. Cam Followers are available in lieu of nylon rollers.

...more

Proportioning Gate

The Proportioning gate (also called flow balancer) is applied for gravimetric proportioning of a full stream of product. It helps attain production of cargo blend and in controlling a stream to maintain a defined throughput.

...more

Pneumatic Flow Control Gate

Feature : Easy to operate , Low maintenance, Longer serving life.

Pneumatic Conveyo

Air Slide (gravity conveyor) is synonymous with an innovative conveying technology - Leading the way with the highest capacity per unit-width in the industry. Our Air Slide fabric weave is designed specifically for aeration of dry bulk materials resulting in even, smooth flow throughout the entire conveying length. A full array of material flow control products – built to the rugged standards expected of Frigate – compliments our Air Slide conveyor product line. Whether transferring material from point-to-point in your plant or fluidizing your silos for load-out, Air Slide performs High capacities No moving parts, low maintenance costs Replacement for high maintenance screw or belt conveyors Low noise Gentle-controlled conveying Adaptable to high temperature applications Multiple inlet and discharge options Clean operation Fabric available for various applications

...more

Pendulum Flap Valve

Feature : Durable , Performance efficient , Longer service life.

Pendulum Flap Gate

Pendulum flap gate valves are used as feed or discharge units and as process air sealing systems. They are characterised by a high degree of operational safety, robustness and ease of maintenance. FRIGATE supplies Pendulum Flap Gates as double or triple pendulum gates with either mechanical or hydraulic actuation systems.

...more

pan conveyor

Whenever hot and abrasive material is to be conveyed, perfect functioning of the conveying system is of vital importance for the efficient operation with minimum down time of plant. The special features of FRIGATE deep drawn pan conveyors are: Inclination angles from 0 - 60 degrees Lifting height exceeding 60m Capacity of more than 1000 t/h Segmented toothed rims Combination with special discharge system for silo discharge with low dust generation Available as reversible system Standardized components for pans, rollers and chains Pan width raging from 400 to 3000mm Reinforced sidewalls, up to 450mm high Contact-free pan overlapping Chain breaking load: 220 to 1800 kN/chain strand Stiffend Chains Inclination angle up to 40 degrees Bolted and stabilized baffles Cut out in the baffles to avoid spillage

...more

Multi Louver Damper

Feature : Sturdiness , Resistance to Rust , Performance efficient

hydraulic truck tippler

hot gas generator

Hot gas generators by Unitherm Cemcon are designed for direct air heating performed by a firing system. Air to be heated is either supplied by a dilution air fan or is delivered from process with high or low temperatures or combinations of both. Hot gas generator engineering for supply or local manufacturing Brick lining material Burner (mono block or special designs) incl. operation valve train and fuel supply system Diluton air fan HGG field instruments for performance and safety control HGG control cubicle

...more

FLOW CONTROL GATE

Flow control gates have a key role in any kind of plant's operation as it the equipment which gives the feed back about the material passing through the line and controls the flow of the material as per the requirement. Flow control gates are designed & supplied with a provision of 0-100% output flow, which can be set as per the desired output. These types of gates are actuated by motorized/ pneumatic actuator

...more

Drag Chain Conveyor

Specialities : Light in weight , Reliable , Competitive prices

DPC Rollers

Surface Finishing : Polished

Application : Rolling Door Use

Size : Standard

Feature : Perfect Dimensions,Tough Structure,Anti-corrosive

...more

Divertor Gate

The Diverter Gate offers an effective method for directing product flow from a single source to multiple destinations. The gate is designed to handle the gravity feed of dry powders, pellets, granules, or any other free flowing product and is hence constructed as being dust tight inside to outside. Flap-gate minimizes leakage between system legs.

...more

Chain Conveyor

Chain conveyors transport the material with help of chains. They are used in such cases, where the transported material could mechanically, or thermally, for example, damage the rubber belt. The material lies straight on the driven chains, or is transported with help of carriers attached to the chains. The production of chain conveyors is always realized according to the specific requirements of customers. Frigate engineers and manufactures dry chain conveyors which can be applied to precipitators, fabric filters, boiler hoppers or cyclones for the collection of fly ash. These units handle fly ash in a dust-tight, air-tight construction which provides dust and fire control. Our chain conveyors can move materials at 8 to 12 feet per minute to a storage and/or disposal location, and can have up to a 35 degree incline. Our conveyors occupy minimum space with maximum materials handling capabilities.

...more

Bucket Elevator Pulley

Feature : High strength , Optimum finish , Rust proof coating

Be first to Rate

Rate ThisOpening Hours