Tube Straightening Machine

Cross Roll Type GMT 6/10 DRIVE CROSS ROLL tube straightening Machines are designed to handle tube of Outer Dia from 6 mm to 170 mm in different models. These machines are based on well proven rotary pressure and deflection principle of straightening, which gives very high degree of straightening ranging from 1 mm to 0.3 mm in 1000 mm. The rolls are mounted in pairs and are drive by two identical motors through totally enclosed gear boxes and box and universal spindel couplings. Features 6/10 work rolls arranged in pairs. Two identical motors driving top and bottom rolls, fixed/variable speed. The Machine can easily and quickly be set when changing from one size of tube to another. Tube can be straightened accurately without surface blemishes. As the tube is retained between each pair of rolls no guides pairs of rolls no guides are required to control the pass of the tube. Machines can be supplied with manual, semi automatic and automatic handling system. Machines can be supplied with pressure sensing unit.

...more

Tube Mill Rolls

GMT, where quality is watchword, makes foray in manufacturing of rolls with typical profiles. May it be selection of raw material, heat treatment or machining, GMT standards are set high to achieve high precision, toughness, maximum wear resistance for greater productivity. Quality assurance: Each and every roll is inspected between process by using sophisticated equipment for dimensions, surface texture and micro structures. The profile is precisely checked with a spring steel template (gauge) made on CNC wire cut machine. Features Computer aided designing. Imported forged alloy tool steel material. Special heat treatment process to achieve isotropic for minimum wear. CNC machining to meet close tolerances. Spring steel template (Gauge) made on CNC wire cut to check the profile. AISI D-2 FORGED STEEL is used for Tube Mill Rolls.

...more

Tube Hydrotester

GMT Hydrotesters are equipped with oil/water high pressure intensifies, automatic handling system and chart type pressure recorders. They can test up to 5000 psi pressure covering various AP1/ASTM/BS standards with single head multiple heads. Features Quick change tooling. Oil & Water Intensifier. Continuous chart type pressure recorders & SG Transducers for every tube results. OD Sealing type. Closed circuits blocking heads for automatic balancing of end thrust on traveling carriage end. Computerised data acquisition system.

...more

Tube End Facer

Twin Head Type GMT offers automatic Cam operated Twin Head End Facer with three tool system. Machine can be installed offline / online to match mill output rate. Features Fully Automatic. Carbide / HSS Tooling for quality End facing and quick tool change / setting. Three Tool System for OD, ID and Face chamfering simultaneously. CAM operated facing Head Feed and Clamp for Safety

...more

Tube Draw Bench

Single/Double/Triple Automatic Feed Type GMT offers Single/Triple tube type draw benches with automatic operations, designed for high yield, perfect quality and precise applications. Features Heavy duty, high reduction gear box Carriage driven by Duplex/ Triplex type double sprocket & chain having rupture strength 6 times of the draw force. Spherical die holder for self alignment. Round tooth type pneumatic clamps to avoid tube slippage. Fully guided carriage with automatic fast return. DC Regenerative Drive for power saving. Automatic tube feeding mechanism. Motorized rotating / indexing type back bench with automatic plug positioning device to minimize handling time. Automatic tube discharge at front frame.

...more

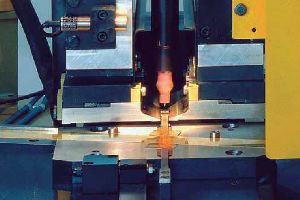

Strip Shear and Welder

GMT Shear & End Welders are most technically advanced of all Shear/Welders available in the world. A wide range can handle strip from 20 mm to 1250 mm wide and 0.5 mm to 10 mm thick can be handle. GMT Shear/Welders are designed to provide fast, accurate means of automatically joining coils on all type of strip processing lines. This increases the productivity as well as eliminates the hazardous manual feeding of new coil into an operating line. Features Ease of operation. Operator’s safety. Semi/Fully automatic. Perfect Indexing. Strip in contact with copper pads for Heat dissipation. Water cooled back up bars. Jerk free perfect horizontal movement of torch for consistent weld quality. Weld strength up to 98% of parent material. Variable speed depending upon Mill speed and strip thickness. Accessories Weld seam planishing roll Post-weld annealers Hole punches Strip notchers Milling Station Weld Fume Exhaust System Backup System for: Welding equipment, Hydraulic equipment Weld Data Recorders Dual Torch Welding System Laser Beam Welding System

...more

SS Tube Forming Mill

Metal Processing Equipment We provide tube forming mill for tubes of ASTM A – Sanitary tube, ASTM A-249 heat exchanger tube, JIS G-3468 large diameter pipe and etc. Bright annealing Forming Mill comes with on line Bright annealing equipment gives bright annealed tubes for heat exchangers, food/ diary, instrumentation industries application. Our stainless steel tube forming mill also comes with in-line bright annealing equipment and eddy current inspection equipment, inside bead rolling system. be, jis g-3468 large diameter pipe and etc. Features Plasma + TIG welding system GMT-TPT Torch GMT-TTT Torch 6M Welding Seamer P+T automatic welding Welding Monitor Plasma Vertical Welder Laser Welding TIG Welding Bright Annealing Tube Forming Mill Inside Bead Rolling/ Seam Polishing Inline Eddy current testing equipment.

...more

Slitting Line

GMT offers Slitting Lines for Hot Rolled and Cold Rolled steel strip to produce high quality of slit strips. These lines are of various designs to suit customer’s requirements in terms of automation level, flexibility of operations and production capacity. The capacity of these lines ranges from 300 mm to 2100 mm width and 0.3 mm to 12.0 mm thickness and coil weight up to 40 M Tons. GMT Slitting Lines produce superior quality of Slit coils with high productivity. Features Automatic operation. Pit/Floor mounted entry coil cars. Cone/Wedge type in coiler drum. Two/Four arm capston. Pit/Flur mounted Eait coil case.

...more

Servo Cut to Length Line

Our CNC Levelling & Shearing machine is high speed Computerised Numerical Control (CNC) and AC Servo Drive for better positioning/Length control systems for cutting accuracy.

...more

GMT Rolls

GMT, where quality is watchword, makes foray in manufacturing of rolls with typical profiles. May it be selection of raw material, heat treatment or machining, GMT standards are set high to achieve high precision, toughness, maximum wear resistance for greater productivity.

Country of Origin : India

Corrosion Resistance : Yes

...more

Push Pointer

GMT Tube Push Pointer Machine is hydraulically operated for PUSH POINTING Tubular product prior to cold drawing. The Machine can handle Tubes having diameter 12 mm. O.D. minimum to 140 mm. O.D. maximum, both in Ferrous & Non-Ferrous material. Large size machines can also be offered. The conventional method of swaging is not only noisy & time consuming, but also produces inaccurate & irregular shaped points. GMT Machines does the pointing with far more ease. It can produce points in four different length upon a maximum of 250 mm. The machine is also capable of Nozzeling the point from 50 to 75 mm. This machine is supplied along with a suitable handling system. The machine office many advantages over the conventional swaging/squeeze operations. Features Considerable material saving. Flexible point length. Common die for pointing and cold drawing. Fixed/rotary type multi sided gripper jaws. Noiseless and vibration free operation. Improved productivity & yield in cold drawing. Automatic handling system with rubberized rollers. Computerized data for acquisition system. No loss of point in multi pass jobs. Perfectly round concentric points suitable for thin or thick wall tubes.

...more

Pipe Threading Machine

We are engaged in manufacturing, exporting and supplying of Pipe Threading Machines. They are manufactured using top quality raw material procured from certified vendors of the industry. Features Automatic Operation. High Production upto 12 Tubes/min for 1/2″ NB. Robust Design. Threading Head imported from japan. High Quality Chasers for accurate threading. Quick tool change.

...more

Pipe Bundling Machine

High speed tube and pipe bundling and strapping machines take the tube directly from the mill and pack the tube ready for transport and sale. No need to store tube in bulk prior to packing. Features Suitable for round/shaped tubes. Quick changeover from round to round/round to shaped tubes. Regular/Irregular hexagonal bundles for round tubes. Square/Rectangular bundles for shaped tube. Automatic/Manual Strapping. Coolant evacuation, Bundle weighting & Marking Systems. Customized and Flexible Conveyor Systems. Suitable for Offline/Online operation with different equipment.

...more

Horizontal Strip Accumulator

Reverse Loop Type GMT offers widest range of Horizontal Accumulators in different models suitable for any type of Tube Mill and Forming line. These accumulators store strips from 20 mm to 1200 mm wide and 0.4 mm to 10 mm thick. This range is covered with various type of designs. Features Fully automatic. High storage capacity. Strip always contained. Easy strip changeover. Flexibility of installation in existing line. No damage to strip surface. Strip entry at any angle. High filling speed (Up to 4 times of mill speed) Filling during mill stoppage. Low maintenance due to fewer moving parts.

...more

ERW Tube Mills

GMT supplies modern HFIW SS & ERW Tube Mills with most advance entry section, quick changing mill section, variety of flying cutoff machines and accurate tooling to meet the stringent requirements of general engineering, automotive, cross country pipe lines, structural, boiler, heat exchanger and other relevant applications. GMT also supplies various tube finishing equipment like End Facing, Threading, Straightening, Hydro testing, Pointing, Drawing & Automatic Bundling etc. The Tube Mills are robust in design, employ highly efficient helical drive system and various levels of automation to suit customer’s requirements. The special shaping stands and Turks head ensure complex hollow section production with precise quality. Cutoff machine can be selected according to productivity & application like Metal Saw Cutoff/ Press Cutoff. Toolings are made of special tool steel to achieve maximum wear resistance and greater life. GMT provides complete services start from project engineering right up to commissioning, startup & initial production assistance and after sales services. Features Fully Automatic Operation Line speed up to 100m/min Quick change raft type design Driven Shaping stands for accurate shapes Accurate cut lengths within + 2mm Buff free rube ends Electrics, Electronics and Hydraulics of world’s reputed manufacturing Project engineering services In-house software designing to suit customers requirements Highly experienced team for startup & initial production assistance Prompt after sales services Easy available of spares

...more

Cold Saw

Specially built cold saw bar and tube cutting machines that are reliable, fast and easily integrated to fit your specific need and application. All of our saws are engineered and manufactured with high quality in the GMT Plant. Features Accurate Length Control +- 2.0 mm. Bur Free Cutting. High Speed upto 150m/min. With Siemens/Tdmechno length Control System. Back lash free Gear Box for Longer Blade life. Suitable for HSS/Carbide/Coated blades. Servo Motor mounted on Alfa Gear Box(Zero back lash) for accurate cut length.

...more

Annealing Equipment

In-Line / Off-Line Annealing Equipment Our machine is built with extreme technical and quality control processes to ensure high performance from them. These machines are known for their robust design, steady performance, easy operation and hassle-free installation.

...more

Strip Shear

Gmt shear & end welders are most technically advanced. A wide range of strips from 20 mm to 1250 mm wide and 0.5 mm to 10 mm thick can be handling.

...moreBe first to Rate

Rate ThisOpening Hours