x-ray inspection machine

X-Ray Inspection Machine provide detection of unwanted contaminants like glass shreds,stones and metal etc. from all unpacked and loose products like snacks, namkeens, nuts etc.X-Ray Machine provides the detection of unwanted contaminants like metal, glass shreds, stones etc from the food products in any type of packaging.

...more

working platform

Working Platform This solid equipment can be used for Multi-head systems as well with Fast Back System. Skid Proof & Safe, Mild Steel.

...more

Tortilla Production Line Machine

Mexican Tortilla is a round shaped flatbread made of corn or wheat flour, which is the basisi for different Mexican food: birritos, tacos, fajitas, etc. Similar dishes with various fillings stuffed in the flatbread are widely offered in fast food outlets, restaurants and at home.

...more

Tortilla Production Line

Tortilla Production Line is a round shaped flatbread made of corn or wheat flour, which is the basisi for different Mexican food: birritos, tacos, fajitas, etc. Similar dishes with various fillings stuffed in the flatbread are widely offered in fast food outlets, restaurants and at home.

...more

Timing Hopper

Timing Hopper & Devices Besides the Timing Hopper following are the other Optional Devices (For supply with Packaging Machines):Dimple Plate, Diverting Gate.

...more

Taralli Production Line Machine

Taralli is an Italian snack food, which is produced similar to other ring-shaped products such as pretzels, bread rings etc. It has specific teisted shape. The main differences of this product are not only shape and recipe but also using different additions ( such as spices and mixes ) in dough preparing. Savory taralli may be flavored with onion , garlic, sesame seeds, poppy seeds, fennel, pepper, chilli or just salt. A perfect alternative to typical bread rings with poppy seeds. Our company offers equipment for taralli production according to classic Italian recipes, using classic recipes of similar bread rings ia also possible. Taralli production process is similar to other ring-shaped bakery products such as pretzels, bread rings etc. The only difference is a forming of the dough. On the bread ring production lines it is a bread ring forming machine and on taralli production lines it is an extrusion and flagellar forming machine with twisting mechanism. On the basis of this often offer our customers to complete the bread ring production line with extrusion and flagellar forming machine with twisting mechanism. It allows increasing the range of output goods on the same line. That means, besides classic bread rings you can produce taralli.

...more

Taralli Production Line

Taralli Production Line which is produced similar to other ring-shaped products such as pretzels, bread rings etc. It has specific teisted shape. The main differences of this product are not only shape and recipe but also using different additions ( such as spices and mixes ) in dough preparing. Savory taralli may be flavored with onion , garlic, sesame seeds, poppy seeds, fennel, pepper, chilli or just salt. A perfect alternative to typical bread rings with poppy seeds. Our company offers equipment for taralli production according to classic Italian recipes, using classic recipes of similar bread rings ia also possible.

...more

Take-Away Conveyor

Take-Away Conveyor This is used for taking away finished pouches away from the bagging machine.Take-Away Conveyor.

...more

Stick Weigher

Stick Weigher Automatic frequency control of vibration for even and precise products distribution, Auto zeroing during operation ensures better accuracy, Stagger dump for applications with large unit size. 1. Automatic frequency control of vibration for even and precise products distribution 2. Auto zeroing during operation ensures better accuracy 3. Self diagnostic alert in pop up window, easy trouble shooting 4. Stagger dump for applications with large unit size 5. Ejection of unqualified weight preventing film and products wasting 6. Live display of individual amplitude for precise monitoring and control of each vibrator

...more

spices processing machinery

Using this spices processing line you get the spices powder as product by processing the different types of whole spices. This is fully automatic line, just feed the spices like turmeric, cumin, coriander, etc. in hopper and the whole process is done automatically.The crusher contains two rotary blades that rotates in opposite directions, the spices are fed between the blades and cut into small pieces.Pin Mill reduces the average sized material to fine powder and maintains the quality of material. It uses air cooling to maintain the temperature of the final product . There are two rotating disks with pinsknifes, the substance that is to be grinded, is fed into the space between disks and through the grinding motion of the disks the material is converted into powder.

...more

Spices Processing Line

Spices Processing Line this spices processing line you get the spices powder as product by processing the different types of whole spices. This is fully automatic line, just feed the spices like turmeric, cumin, coriander, etc. in hopper and the whole process is done automatically.

...more

Servo Auger Filler Power

Weight : 750 kg

Rotary Collecting Table

Rotary Collecting Table The rotary collecting table is used for collecting the pouch food from packing machine and wait for next part of the packing operation. Its made of stainless steel and has adjustable rotary speed.

...more

Roasting Oven

Roasting Oven These ovens are widely used for drying all kinds of stick, piece, grain food etc. User can choose different types of dryer according to layer, length or energy.

...more

Ready To Eat Food Processing Line

Ready To Eat Food Processing Line is quickly frozen up to -40`C so that all the water molecules get frozen and then pressure is increased up to its triple point by placing it in a vacuum so that the ice crystals that formed while freezing process get transformed directly to the gaseous state and are vacuumed from the system and the product gets completely dehydrated . 98% of water gets removed by this process, because of no water, the product can be preserved for long time.

...more

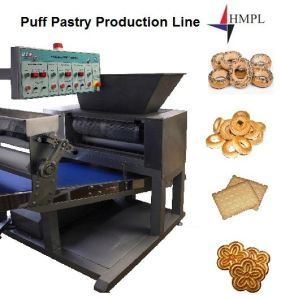

Puff Pastry Production Line Machine

>> Puff pastry and dough >> Hard biscuit, soft biscuit and cracker >> Bread rolls >> Sponge bases for cakes salty and sweet bread sticks >> Taralli and bread sticks grissini >> Filo dough and products made of it (burek, vertuta) The priority principle of our company is the individual approach to each client, as well as to the development of the project, starting from the configuration of lines and the design of confectionery machine layout to installation and commissioning works. We try to give full attention to the specifics of every customer’s business, the needs and requirements of his production. We take into account conditions of production and technological processes, provide constant technical support and advice. We offer not only standard production lines, but also individual, and even exclusive developments. Besides, we offer not only lines in the set, but also separate units or component elements of confectionery equipment for sale.

...more

Puff Pastry Production Line

Puff Pastry Production Line Sponge bases for cakes salty and sweet bread sticks, Taralli and bread sticks grissini, the needs and requirements of his production. We take into account conditions of production and technological processes, provide constant technical support and advice.

...more

Popcorn Processing Line

Popcorn Processing Line HMPL Provides popcorn processing plants from small to large scale industrial solutions. HMPL has more than 20 years of experience in Food Processing and Packaging solutions exporting to various countries around the world. For Sugar based flavors including Caramel pop corn, chocolate pop corn, strawberry cream pop corns etc.

...more

pick fill seal machine

Easy to operate: -PLC controller and color touch-screen, fault indication on the touch screen. -Unmanned in weighing and packing process, machine alarm automatically when failure. -Only about 10 minutes to change different size pouches. Frequency control: -Speed can be adjusted by frequency conversion within the range. Easy to clean: -The auger filler and conveyor can be opened for cleaning completely. Optional Accessories -Rotatory packing machine -Auger filler (a) Auger conveyor (b) Vacuum Conveyor -Check Weigher -Metal Detector -Output Conveyor Reliability Safety: -No pouch/incorrect pouch opening-no-fill-no-seal, machine alarm. -Machine alarm and stop when the inadequate air pressure. -Safety guards with safety-switches, machine alarm and stop when the safety guards are opened. Hygiene: -Hygienic construction, the product contact parts are adopted SUS 316 stainless steel. -Imported engineering plastic bearings, no need to oil, no contamination. -Oil-free vacuum pump, avoid the pollution of the production environmental. -Dust cleaning devices avoid the powder flying all over. Standard Accessories -PLC controller -Date printer ( Ribbon type ) -Pneumatic components -Temperature controller -Vacuum pump -Discharge conveyor Packaging Range Bag Type,Flat bag, portable bag, standup bag, zipper bag, all kinds of compound bags. Bag size: 200 model Min. width 100 mm Min. length 100 mm Max. width 200 mm Max length 300 mm 300 model Min width 150 mm Min length 100 mm Max width 300 mm Max length 330mm

...more

Pick Fill Seal

Pick Fill Seal -Unmanned in weighing and packing process, machine alarm automatically when failure. PLC controller and color touch-screen, fault indication on the touch screen. Speed can be adjusted by frequency conversion within the range.

...more

pellet frying line

HMPL is a leading manufacturer and exporter of Pellets Frying lines in India. HMPL caters to various capacity of pellet frying lines from small and large scale fryers. HMPL Frying lines are automatic lines which require minimal human interaction.Our fryers are low oil consumption and fuel efficient frying systems. Our frying lines have low running costs, easy to use and clean. HMPL Frying lines provides homogeneous frying keeping the texture, color and taste of the pellet intact and consistent throughout.

Capacity : 90 KG/Hr -1180 KG/Hr

...more

Pellet Fried Snacks Food Processing Line Machine

HMPL is a leading manufacturer and exporter of Pellets Frying lines in India. HMPL caters to various capacity of pellet frying lines from small and large scale fryers. HMPL Frying lines are automatic lines which require minimal human interaction. Our fryers are low oil consumption and fuel efficient frying systems. Our frying lines have low running costs, easy to use and clean. HMPL Frying lines provides homogeneous frying keeping the texture, color and taste of the pellet intact and consistent throughout.

...more

Pellet Fried Snacks Food Processing Line

Pellet Fried Snacks Food Processing Line to various capacity of pellet frying lines from small and large scale fryers. HMPL Frying lines are automatic lines which require minimal human interaction. Our fryers are low oil consumption and fuel efficient frying systems. Our frying lines have low running costs, easy to use and clean. HMPL Frying lines provides homogeneous frying keeping the texture, color and taste of the pellet intact and consistent throughout.

Capacity : 90 KG/Hr -1180 KG/Hr

...more

pasta production line

Pasta production implies using of pasta production equipment: such basic units as flour sifter, macaroni extruder, preliminary drier (trabatto), main drying complex as well as packaging machine. If necessary, basic automatic line for pasta production could be completed with additional devices and machines. One of the most important criteria in the selection of equipment is its capacity. Besides, a choice of production line is defined by a size of enterprise, available production space, type of the most optimal energy source as well as types of pasta products.

...moreBe first to Rate

Rate ThisOpening Hours