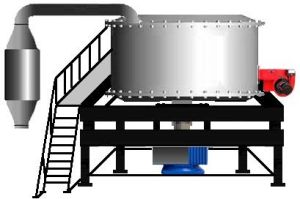

Universal Melting Tilting Furnaces

Universal melting tilting furnace are helpful in delivering increased productivity with outstanding energy saving capacities. These are used for die-casting applications for bulk melting process. Oxidized materials including low and high metal energy scrap, feedstock and dross have been melted in tilting rotary furnace. When the performance is compared with other tilting rotary furnace range then there are certain benefits including low energy usage that results is 15 parent saving. High level of metal recovery with 2-5% of increase in recovery. Increased level of productivity that is about 50 times is gained. Labor savings are also achieved because it is an automated process and only one operator is needed to operate different furnaces at a time. Savings of cost and time along with efficiency is gained with the help of innovative design that is backed-up by latest knowledge and in-depth research. Fuel choice is made in accordance with local conditions. Oil, gas or oxy fuel is employed when needed. Proportionate combustion system is used for double pass burner firing to mix precise amount of fuel with the oxygen. Accurate real time ratio of this proportionater helps in gaining maximum level of fuel efficiency results. Process control is also gained. For instance, smoke during start of a charge or with fire with reducing atmospheric effects for saving metal oxidation. There is also a unique door management system that helps in titling and firing at the same time. This aids in getting a good mixing of charge. Faster and high melting recovery is achieved with this process. All types of scrap including bulky and oversized material can be charged at a faster rate. Door openings are present at a diameter of 79 degree. Charging machine that is fully integrated allowed fast charge and improved melting. Less energy usage with more production is assured.

...more

Traditional Melting Furnace

Certification : ISO 9001-2008

Weight : 10 TONS

Condition : New

Voltage : 415

Application : Melting Furnace

...more

Tilting Rotary Furnace for Aluminum Melting

We offer a flexible and universal design of tilting rotary furnace that is the best solution for aluminum scrap recycling. All the scarp that is formed can be easily recycled to gain better results. A friction drive wheel system is maintained to rotate the furnace. Along with this a single door is also employed with either horizontal or vertical rotation that has a pendulum type switch. It involves a high efficiency system that is fixed on the furnace with tiles. It exhausts with a fume collection housing or with a rotatory joint. Traditionally these furnaces have been static in nature but now tilting deign have been added that has helped in bringing improvement in their efficiency. Now work is done in lesser time. Cost of process is low and yield is also high. Engineered rotary furnaces are used to fit the needs and demands of all clients with different requirements. The air burner is provided with fuel oil or with gas. In any case configuration can be changed for static or tilting design. The objective of our company is to design a system with high performance, coherent production tools that can help process a wide range of commercial scarp with the help of salt free technique. Latest melting practices that are present in the market are employed. These latest systems has also helped in elimination of the need of flux melting procedure. Working conditions for furnace men have improved to a great extent. It has also helped in melting a wide range of feedstock. Elimination of metal pollution has achieved as well. It has also facilitated homogeneity and charge mixing. The chances of self-cleaning are also high with high thermal yield and low range of energy consumption. Finally faster and efficient system is achieved that has 2-3 times higher yield than that of traditional furnaces.

...more

THERMOCOUPLE FOR HIGH TEMPERATURE

Standard TYPE -R THERMOCOUPLE high temperatures sensing probes are made with a ½” NB (21.34mm) support and a 15mm OD ceramic sheath. The supports are made from 316 stainless steel. A 2 way ceramic terminal block is housed in a large alloy head.

...more

Tetsed Rotary Melting Furnac

Type : Arc Furnace

Voltage : 415

Warranty : 12 MOnths

Application : Melting Furnace

...more

Shaker Hearth Heat Treatment Furnace

Shaker Hearth Heat Treatment Furnace in fact called Reciprocating and Rotary Agitation write Furnaces while responding shaker movement bestows idleness to the work plate display in the hearth of the heater with uniform warming to the principle workload general case profundity warm is accomplished. The Furnace are by and large utilized for the light weight parts that are to be carburized to case profundity of 0.3 mm. Shaker hearth heaters utilize a plate for the vehicle of Work pieces from a bay zone to a release zone, and such plate are ordinarily upheld inside the heater upon metal or headstrong slides or upon rollers or notwithstanding holding tight arms. Such kinds of backings are liable to very fast Wear and their restoration requires expulsion from the Furnace. Primary Process of the Furnace: Austempering : increment quality, sturdiness, and diminish mutilation. Solidifying: increment the hardness of a metal for better protection. Remarkable Features: Pleasantly Welded and Painted Mild Steel Structure with appropriately strengthened with reasonable size of edge and channel. Shaking Tray is made out of Stainless Steel 310 review which can manage top of the line operational stun. Heater is given the programmed control board for the operation. Steady temperature in heater because of subdivision of heater in to warming drenching zones. Segment Processed: High Carbon clasp. Hand devices, spanners, bearing, chain, locks, vehicle parts and so on. Solidifying of little utensils parts. Austempering of auto-segments. Solidifying of protection Alloys. Extra Information: Thing Code: HTF-7 Pay Mode Terms: L/C (Letter of Credit),T/T (Bank Transfer) Port of Dispatch: Nhava Sheva, Kandla Port Generation Capacity: 4-8 every year Conveyance Time: 30 days Bundling Details: High Quality Plastic Wrap Wooden Box with Fumigation

...more

SAND MOULD HARDNESS TESTER

MECHANISM:Consists of dial indicator and special geometry plunger to read hardness of Green Mould from 0 to 100 Nos. Sand Type: Green Sand Test: Determines hardness of mould Application: To find out the Green mould hardness of the sand mould prepared by any method e.g: Hand molding, Jolt Squeeze molding etc.

Height : 165

...more

Salt Bath Steel Melting Furnace

Application : Heat Treatment Furnace

Certification : ISO 9001-2008

Type : Resistance Furnace

Voltage : As Per Model

...more

Salt Bath Furnace

Indotherm Equipment Corporation makes Salt-Bath Furnaces for Heat Treatment of Steel or brilliance Metals. We can supply Electrically Heated and in addition Gas-worked heater according to client needs. Our salt shower heater is made out of High Quality stubborn from rehashed brands and pleasantly welded with gentle steel metal sheet. Our Manufactured SS pot, cauldron is tried ultrasonically before it is loaded with liquid salt into which work is inundated for either warming or cooling. Our produced pot is equipped for dealing with overwhelming salts, for example, nitrates, nitrites, harsh pop, chlorides, carbonates, and cyanide.

...more

Rotary Metal Melting Furnace

Type : Arc Furnace

Warranty : 12 MOnths

Weight : 10 TONS

Condition : New

...more

Reverbratory Furnace For Scrap Melting

Reverbratoy furnace for scrap melting are used for procedures such as scrap recycling and alloying units. In these case full burners are used. Melting is done after the charging of the scrap in the furnace. Processing of prepared metal for its alloy correction can also be done in such cases. Transportation is done in order to end the application. Reverbratoy furnace for scrap melting are usually batch type furnace can their application can be wide. Several types of scrap can be processed in these Reverbratoy furnace for scrap melting. Fuel continuous of the furnace is around 1000KWH/ton when temperature is 7200C. Metal loss of approximately 4 percent happens in this case. Mutual operations have to be carried too and metal tapping is done with the help of hydraulic tilting system or plug system. Reverberatory furnace for scrap melting can be customized according to the needs of the client in different ways to achieve: Holding of metal or melting in one single chamber Refractory also would not have any blind corners so it would be easier to clean the furnace properly after its usage A plug or hydraulic tilting system can be employed for the sake of metal tapping Air recuperator can be employed to equip the furnace A full access can be given with eth help of a large door so cleaning and loading can be done properly

...more

Reciprocating Heat Treatment Furnace

Condition : New

Application : Heat Treatment Furnace

Certification : ISO9001 2008 CE

Weight : 1Ton

Voltage : 380V

...more

Pollution Control Equipment

Oil refineries & petrochemical Pulp & paper Steel, metals, & glass Aluminum, copper & non-ferrous smelters Fossil fuel boilers & waste incinerators Chemicals & plastic Fertilizer & mining

...more

PNEUMATIC RAMMER - FOUNDRY SHOP

Features Heat treated – cylinder & chromes plated piston significantly extended tools life. Special seal – prevent ingres of sand and maintains positive air seal. Simplate Valve – For Smooth, Powerful operation. Teasing Throttle – for precise control. Air Powered – flow of air through tools keeps air hammers, cool to touch, won’t overheat. Well balanced smooth operation tools – easily guided by one person. Sturdy design – Easy to maintain.

...more

oil fired furnaces

oil fired forging furnace

Indotherm Equipment Corporation is the maker and Supplier of Reheating Furnace, Forging Furnace, Pit Type Furnaces, Aluminum Melting Furnace, Recuperator, Industrial Burner and associated types of gear in the need of Heat Treatment Industry. Organization PROFILE-FORGING INDUSTRY Offering the sparing strategy in zones of following fashion plant forms with best tech Forging heaters and stoves. Answer for Heating for Forging, Stress assuaging in the wake of fashioning, Heat treating,Pre-warmers, Air cooling units, warming of end and focuses. Assembling Since 1990 we are producing world class fashioning heater for warming and warming substantial steel ingots, metals and steel parts. Heater are made with top notch high temperature unmanageable temperature protection up-to 1800 Degree Celsius. The development will be work to long last thus will the general heater. Fashioning PROCESS DETAILS Heater can be ordered into gas produce and oil fashion where gas manufactures normally utilizes propane and petroleum gas as the fuel and in fuel Furnace oil , diesel and light fuel oil can be sorted. We can likewise fabricate custom form heater differ in size and development, from extensive Chamber utilizing a major burner with a blower or a few air burners to produce the material. A few fashions process Also known as: Level Die Forging, Hand producing, And Smith fashioning. Additionally unique sorts of metals will have an alternate components included when producing them, some will be simpler to fashion than others. Extra Information: Thing Code: FO100K Least Order Quantity: 1 Unit(s)

...more

non ferrous melting furnaces

Metal Pouring Heating Melting Ladle Furnace

Weight : Approx 1 Ton

Warranty : 12 Months

Type : Material Handling Equipment

Certification : ISO 9001-2008

...more

Mesh Belt Conveyor Furnace

Condition : New

Certification : ISO9001 2008

Type : Resistance Furnace

Application : Heat Treatment Furnace

Voltage : Three Phases 380V 50-60HZ

...more

Long Lasting Rotary Metal Melting Furnace

Condition : New

Weight : 10 TONS

Litharge Furnace Design

Litharge fabricating is a bunch procedure. The Furnace is pre-warmed to 575-600°C by a gas/oil terminated burner. Lead Oxide is metered and sustained into the heater. The material is blended and fomented inside the heater. The temperature is kept up between 575-600 °C all through the response. The response is exothermic, thus less fuel is utilized to keep up the temperature.

...more

LIFT OUT CRUCIBLE FURNACE (AUTOMATIC OPERATION)

Lead Refining Pot

Lead reused from utilized lead corrosive batteries or different sources (Secondary Smelting) by means of the Mini Blast Furnace or Rotary Furnace course, contains parcel of pollution and undesired segments. Then again, Lead required for battery fabricating is either delicate Lead with 99.97% virtue or hard Lead of changing Antimony creations.

...more

Lead Battery Recycling Plant

In industry ULAB or Used Lead Acid Batteries are considered to be the biggest lead source all over the world. Complete lead recycling solutions are provided by our company. Plant lead extrusion and recycling is done and usable form of lead is produced. These are also known as scrap recycling or used lead acid battery recycling plants. The main parts of the lead recycling plants include battery draining case for recycling of the battery. An acid neutralizing area for drained acid is maintained along with battery case washing effluent. A battery breaking segregation system with battery cutting machines whose size depend on the scale of operation is manufactured. We also provide rotary furnace as well as coal furnace. Client’s need for recycling of lead bearing waste are kept in mind while designing it. Smelting or melting of lead is a hazardous operation and here air pollution control is of critical importance. Keeping in view this need of the system we provide an efficient air pollution control system that is highly compatible with the furnace that is being prepared in our industry. Along with this, fugitive emission control system is also catered that is compatible with the rotary furnace. It is helpful in control fugitive emission from the furnace.

...moreBe first to Rate

Rate ThisOpening Hours