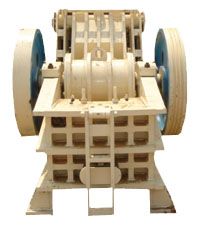

Double Toggle Jaw Crusher

Get Price Quote

We hold expertise in providing Double Toggle Jaw Crushers, which are made using finest quality of materials. The Double Toggle Jaw Crushers offered by us are known for their robust construction, effectual functioning and less wear and tear. Moreover, these crushers are made available to the clients in varied sizes to suit their specific requirements. Specifications : Moves with the use of pitman filled with grease chamber jaw crushersLess rubbing actionHigh impact forceLess dust formation Used For Crushing : RocksCoalStonesRefractoryGlass

48x40inch Jaw Crushing Machine

800,000 - 7,000,000 Per Piece

1 Piece (MOQ)

Jaw Crusher, as the name suggests, works on the same principle as the human jaw. It has one stationary jaw (like the upper teeth set) and the other movable (like the lower teeth set) with the material to be crushed (food to be chewed) fed inside the two jaws (mouth) and crushed (chewed) to the desired size and discharged (swallowed) to accommodate fresh input of material (food). "CCS OSTEM" strives to attain the same perfection for its Jaw Crusher like the human jaw devised by Mother Nature!!! Being at the primary crushing stage of the Crushing & Sereening Plant, the Jaw Crusher is subject to heavy shock load. Performance wise, it must discharge output material sized enough to match with the subsequent crushing stage, and at compatible output capacity. It is also essential to incorporate features to with stand the adverse conditions prevailing at remote sites. The "CCS OSTEM" Jaw Crusher has heen designed and manufactured keeping all theserequisites. Salient Features Based on the Single Toggle Mechanism, the Toggle Plate in "CCS OSTEM" Jaw Crushers is oriented in a manner so as to produce magnified stroke for best results. Proper Cavity Opening vs. Cavity Depth ratios for all models prevent blockage of the material to be crushed. Smooth flow of the material within the machine enhances crushing capacity. Main Body, made from tested quality M.S. Plates of required thickness, is duly annealed at. our in-house computerized oil fired furnace. The Swing Jaw Crank Shaft Assembly, which also houses theinner bearings, has been designed to prevent any dust entering it. Bearings are fit using latest technique for longevity and optimum performance. "CCS OSTEM" Jaw Crushers incorporate sturdy Hydraulic arrangement for adjustment of Closed Side Setting (C.8.8.). The design is operator friendly and flexible for varied settings. All cast items used are as proper industry standards in terms of metallurgy and processing. Wear resistant high grade austenitic Manganese Steel is used for Jaw Plates and Side Plates.

Best Deals from Jaw Crusher

bone crusher

Get Price Quote

1 Piece (MOQ)

Jaw crusher

150,000 Per Piece

Manufactured using heavy ribbed mild steel plates, our Jaw Crushers come with hick welding joints. We are a trusted Manufacturer, Supplier and Exporter of Jaw Crushers from Haryana. The Jaw Crushers we make available are used in many industrial fields, such as building, chemical, chemical fertilizer, metallurgy, mining, non metal, abrasive, bearing materials, ceramic, steel, thermal power, bricks & tiles, coal industry, etc. One can obtain the Crushers at affordable rates. Details : Spring loaded safety tie bar is enabled which protects aw stock against overloading Double Toggle / Single Toggle Jaw Crusher Features : High reduction ratio Even product granularity Simple structure Reliable operation High reliability Top crushing performance Wedge setting adjustment Fast and simple maintenance Easy and less costly to install Excellent total crushing economy

Jaw crusher

Get Price Quote

We provide Jaw Crusher that has a body made of single plate welded construction welded with MIG welding technology which makes it very strong. We provide specially designed strong pitmen having four bearing mounted to eccentric shaft of special steel which is rigid in construction. The lever is of strong design and M.S. fabricated from steel plate. The jaw plates are of two types, swing & fix jaw plates made of manganese and steel casting having 12 & 14% manganese. For the smooth functioning of these parts, we also provide hinge pin, fly wheel, pull back rod and spring. Features : Crushes the material by pressure.Can take down rocks easily without any obstructions.Easy discharge of the rocks from the bodySturdy design, heavy bearing shaft & fly wheel to crush even a hardest type of rock like iron ore, Granite etc Block provided at Pitmen side.No skilled operator is required because of its simple construction Applications : Black Trap RockGraniteRiver GravelBlast Furance SlagCarborundum (Silicon Carbide)EmeryCalcicum Carbide (Fused)Bauxite VFerro Manganese, Ferro Silicon, Ferro Vanadium,Lime StoneCoal, Coke, Petroleum Coke etc.Iron OreManganese OreQuartzite Click Here for Capacity & Power Chart.

Jaw crusher

Get Price Quote

Crushton Engineers is the principal Manufacturer and Supplier of the Jaw Crushers, which are hugely demanded by the clients in the nationwide markets. These Jaw Crushers are, diligently designed by the experts that ensure their ability to perform in the hardcore industrial applications. Used For In taking boulder & crushing it to smaller sizes stone of different sizes GraniteCockBauxiteIron oreLimestoneCalcium carbideRiver gravelCarborundam Functioning Jaw plates that are made up of MN Steel for the crushing of fed materialOne Jaw plates is fixed and another is moving (swing jaw plate) which move by the thrust of toggle plate with takes the force by pitmanRotation of eccentric shaft is achieved by the flywheel driven by the V. BeltV. Belt is connected to electric motor or diesel engine, as prime forceIn Single Toggle jaw crusher, lever is no seperate parts rather pitman itself works as lever & they are two in one unitPrincipal practice is to crush the material without rubbing Main Parts Of Jaw Crusher BodyFabricated with tested quality M.S. PlatesReinforced by the M.S FlatsProviding as horizontal members & vertical members to the bodyLeverFabricated with M.S platesConsists of M.S pipe, Forged M.S pin, bushes etcPitmanAssembly has main body of mild steel and M.S pipe and EN 8 / Forged Steel cranck shaftPipe holds one eccentric shaft & 2 nos bearingsAt bottom of the pitman body the toggle bearings are inserted to house the toggle platesJaw PlatesJaw plates are made of MN Steel Containing 12 to 14%MnConforming to I.S.276Toggle BearingsToggle bearings are either of cast MN steel or tempered steelFlywheelFlywheels are two in numbersOne flywheel is used for balancingAnother is prime mover that rotates and hence rotates the Cranck Shaft alsoUsed for rotation on electric power or diesel engineToggle Block and Viz. BlockC.I materialsProperly machinedProvided in the rear portion of the jaw bodyToggle Block is to control thrust produced in the pitman Used to Adjust/set the stroke of the swing jaw plateLubricationProvision for greasing the bearing, eccentric shaft end and pin etcSelf-aligning double roller bearingsCylindrical roller bearings are fitted providing grease holding spaceLoss of grease should be compensated by the repeat greasing after every 10 days time constantlyThe loc-servolin-15 oil or Anti friction grease-3/equivalent should be used as lubricant grease.Anti friction grease-3/equivalent should be used as lubricant grease Specifications Size in inchFeed SizeT.P.H. CAPACITY WITH DIFFERENT JAW SETTINGS25mm40mm50mm60mm75mm100mm125mm150mm175mm200mmBHP7"X 12'5"7'159' X16'7"12162426352510' X20"8"3036423012' X24'10363865851064015'X30'134252731011301555018'X36'165161721011301556024"X36'20901161401707520"X42"1810014017120510020"X48"1814417021024010036"X42"32175210233270125Size in inchCapacity in tones per hour with jaw setting atBHP25 mm30 mm40 mm50 mm60mm75mm2520' X4'1214163524" X 6'151622324030' X6"18202635454036' X 6'243239505042" X6'4150625048" X9'49627450 Note : Specifications, Capacity and Material May Be Changed By Us At Our Desertion At Any Time Without Prior Notice.

Jaw Crushing Machine

Get Price Quote

HP Infrastructure brings you the BAZER range of versatile single toggle jaw crushers. BAZER Jaw Crushers offer customers high capacity, low maintenance and application versatility. Quality BAZER Components ensure reliable operation. With a moderate investment cost, our jaw crushing system offers operators the flexible production and high capacity output necessary to remain competitive. BAZER Jaw Crushers are suitable for all types of applications like aggregate, quartzite, sandstone, iron ore and other metallic ores. Designed to excel in even the most difficult working conditions, BAZER jaw crushers have proven their worth as the true workmate in various crushing applications. Features: Large eccentric shaft for greater stroke in the upper chamber High angle toggle plate increases stroke in lower chamber Large flywheels have greater inertia for crushing in toughest applications Deep pitch gripper jaws for maximum reduction Jaws available in options of half bellied and full bellied High rib concentration for toggle support Drop forged, heat-treated shaft to withstand the pressures of high reduction Heavy duty stress-relieved welded steel base for higher durability Spherical self-aligning roller bearings Hydraulic toggle seat adjustment Close tolerance machining of jaw backs and seating surfaces Reversible key plates for extended life

Jaw crusher

Get Price Quote

Crushing is managed by pulping or material by law plates dully placed at due angle for maximum output and minimum consumption of power and exerting appropriate thrust on the crushing zone as well on the whole body. The basic thrust is obtained by the eccentric movement of pitman which is transferred to lever with the help of rear and front toggle plates connect the pitman with lever and toggle block. The lever consists of one jaw plate (moving) which exerts the thrust on the other jaw plate (fixed) on the body. This thrust crusher the material between the jaw plates. Then crusher material travels down ward by gravity and falls on the discharge chutes. The sizes of products can be adjusted by cutting or increasing the toggle plates and lowering the wedge blocks.

Double Toggle Jaw Crusher

Get Price Quote

Product Details: Brand Abhishek Enterprises Material MS and Iron Dimension 36x6 inch, 36x8 inch, 42x6 inch, 42x7 inch, 42x8 inch, 42x9 inch, 48x10 inch, 42x10 inch Our firm offers a varied range of Double Toggle Jaw Crusher Secondary Machine.

Jaw crusher

Get Price Quote

We are the main supplier of this product.

Single Toggle Jaw Crusher

Get Price Quote

conveyors parts, Double Toggle Jaw Crusher, Rotopactor

Double Toggle Jaw Crusher

Get Price Quote

Double Toggle Jaw Crusher, Jaw crusher, Rotopactor Machine, Sand Classifier

Industrial Jaw Crushers

Get Price Quote

Industrial Jaw Crushers, Rotopactor Machine, Sand Washing Machine

Jaw Crushers

Get Price Quote

stone conveyors, industrial jaw crusher, precision jaw crushers

Jaw crusher

Get Price Quote

Jaw crusher, Impact Crusher, Rotopactor, Stone Crusher

Jaw crusher

Get Price Quote

Jaw crusher, Granulator, Roll Crusher, Rotopactor

Jaw crusher

Get Price Quote

Jaw crusher, steel hoppers, Trough Belt Conveyors

jaw crushing

Get Price Quote

jaw crushing, Inclined screens, Pan Conveyors, Crushers, Washing Plant

Jaw crusher

Get Price Quote

Jaw crusher, Stone Crushing Machine, Roll Crusher, Rotopactor Machine

Jaw crusher

Get Price Quote

Jaw crusher, IMPACTOR, Vibratory Feeders

Jaw Crushers

Get Price Quote

cone crushing plants, Vertical Shaft Impactor, Conveying Equipment

mega jaw crusher

Get Price Quote

mega jaw crusher, ace power cone crusher, Manganese Steel Castings

Jaw crusher

Get Price Quote

Jaw crusher, Stone Crusher

Jaw crusher

Get Price Quote

Jaw crusher