Ultra Isolation Transformer

245,000 Per Piece

Speciality : Precisely designed, Reliable performance, Minimum maintenance

Phase : Three Phase

Cooling Type : Oil Cooled, Dry Type/Air Cooled

...more

Three Phase Rectifiers

Application : Three Phase Rectifier

Input Voltage : 380V, 440V

Phase : Three Phase

...moreSilicon Power Rectifiers

Phase : Three Phase

Frequency : 50 Hz

Servo Voltage Stabilizers

485,000 Per Piece

Frequency : 50 Hz

Phase : 3- Phase

Feature : Industry proven design, Maintenance free, Hassle-free performance

Output Voltage : 400 V +/-1%

Cooling : Natural Oil Cooled (upto 5000 kilo-volt-ampere ) / Air Cooled ( upto 500 kilo-volt-ampere)

Type : Indoor / Outdoor

Correction Rate : 6-8 V / Second

...more

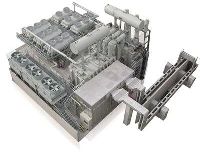

rectifier duty transformers

Linear Voltage Regulating Transformer has been designed to meet a wide range of heavy-duty industrial application as well for Electricity Supply Utilities. Globally, these have become an established method of control, wherever continuously variable on-load control of voltage and power is needed. These can also be used to control many industrial processes like adjusting temperature, flow speeds, drive speeds, etc. to a pre-set programme.Voltage Regulating Transformers & Regulating units combine fixed ratio transformers with regulating transformers to extend their rating, connection, designs range from low order KVA's to several hundred KVA as a stand alone unit. Using multiple voltage regulators, in combination with fixed ratio

...more

Oil Cooled Distribution Transformer

Speciality : High efficiency, Proper functioning, Long service life

Phase : 3-Phase

Cooling Type : Oil Cooled

Frequency : 50Hz

...more

Automatic Voltage Regulator

441,000 Per Piece

Phase : Three Phase

Automatic Voltage Controller

If you are getting high voltage more than 230 VOLTS SINGLE PHASE/400 VOLTS THREE PHASE Introduction Voltage fluctuation is a common phenomenon in every part of the country. The industrial units running round the clock, usually face the problem of low and high voltage. 90% of industrial load motors . Electric motors draw considerably high current at low & high voltage. This higher current affects the electrical motors ( particularly smaller capacity motors upto 7.5 H.P.) in three ways: Higher current produces higher losses in electrical motors which causes premature failure winding. These higher losses of electric motors also increase the losses of cables, switches, transformers and other associated equipments. For smooth continuous operation of motors, overload relays are usually set at 20% higher setting. Adverse Effects of Single Phasing The line current increases by 1.5 times. If the relay setting is at 15-20% higher than actual operating current then the relay will take 4-6 minutes to trip. The motor ( particularly smaller capacity motors upto 7.5 H.P) cannot withstand this high current for such a long time and in most of the cases it burns out before the relay trips. Heavy short circuit current flows through the relays, contactors, cable etc. Under this condition when the relay, contactor trips, they produce sparks and some times burst. This further damages the switch gear and in some of the cases may cause fire also. with the installation of the stabilizer and maintaining 390/400 volts, the motor will operate smoothly drawing 15-20% lesser current and correspondingly the relay setting can be reduced by 15-20% In case single phasing occurs, the relay will trip in 40-50 seconds. The motor can withstand the high current fot this period and will be safe. Also, the relays, contactors, switchgears, etc. incorporated with the motor will be safe Who Needs A Stabilizer The industrial units having acute /higher failure rate of Electrical Equipments such as bulbs tubes, chokes, starter, contactor coils & motors (particularly smaller capacity motors upto 7.5 H.P) etc. should verify that it may be due to HIGHER voltage. You may note down Hourly readings of voltage variation for few days. If you find that input voltage is above 230 volts single phase / 400 volts Three phase even for few hours a day, then you definitely require a stabilizer. How to Access Higher Losses & Low Power Factor in Industrial Units Without Installing Stabilizer Note down hourly readings of current and voltage of one motor operating at constant load for 2-3 days. From the different readings you will observe that the current drawn by the motor is minimum at 390/400 volts as compared to the current drawn at other voltages. This means that power consumed by the motor is minimum at 390/400 volts. Also note down hourly readings of voltage and K.W. from your Electronic Energy Meter for 2-3 days. From the readings you will observe that K.W. is minimum at 390/400 volts in most of the readings as compared to the higher voltage. If you find that the above collected details are true then you will certainly have the advantages after installing the Servo voltage stabilizer as mentioned on succeeding page. The table below gives approximate quantitative advantages of Automatic Voltage Controller at various voltage fluctuation levels. Jindal's" Make Roller Type Regulator Conventional Make with Carbon Brush Regulator Power consumption is 0.5 to 1.5% depending upon the input voltage range Suitable for continuous 100% duty cycle Life at full load is 15-20 years Five years unconditional guarantee Negligible losses in full boost & buck condition Power consumption is 2 to 7% under similar conditions Suitable for only 30% to 40% duty cycle Maximum life is 2-3 years at full load Normally guarantee for one year Max. Losses in full boost and buck condition

Type : Indoor / Outdoor

...more

AC to DC Rectifiers

Phase : Three Phase

Application : AC to DC Rectifier

Be first to Rate

Rate ThisOpening Hours