Solar Garden Light

7,500 - 15,000 Per Piece

VMC Machining Fixture

Get Price Quote

we provide all types of vmc cnc machining tools and fixtures. mechanical, pneumatic, hydraulic

Best Deals from Light Fitting

Honing Machine Fixture

2,000 - 30,000 Per Piece

10 Piece (MOQ)

Tea Packaging Machine

1,250,000 - 1,300,000 Per piece

1 piece (MOQ)

Fabricated Jig Fixture

Get Price Quote

Tapping Machine

Get Price Quote

Tapping Machine, battery operated hand tool

jig fixture

Get Price Quote

The material that is used for the production complies with high quality standards and quality-proved by the experts. Also, we make sure that the raw material is sourced from the trusted places. We will not let you wait much, as we have trustworthy shipping facilities available to deliver the same in set time.

Kurkure Packing Machine

Get Price Quote

Pipe Straightening Machine

Get Price Quote

Accurate Pipe Straightening without surface blemishes. FixedVariable Speed. Hydraulic lift in entry bottom roll for smooth entry of tube. No guides required to control tube passing. Built-in indicators for accurate roll setting. Easy and quick changeover from one tube size to another. Pressure sensing unit with digital display for thin wall Tubes. U-Type inlet and L-Type Outlet semi automatic tube handling system. Totally enclosed vanishing roller type automatic tube handling system.

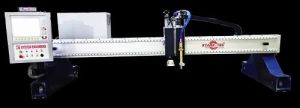

Cutting Machine

Get Price Quote

1 Piece(s) (MOQ)

Combining our expertise with the technology that we possess, we take the responsibility to deliver utmost quality Cutter Machine to the customers. We are a quality-conscious firm and for ensuring high quality of the products, we dedicatedly work in tune with the defined industry standards.

Jig Fixtures

Get Price Quote

Defined as one of the celebrated names in the market, we are involved in offering excellent quality Jig Fixtures. We have superior storage capacity to safely store the extensive product range that we offer. Our massive and well-maintained storage space is well-connected with the shipping unit. Features : Fine finish Corrosion resistance High durability

Spices Packing Machine

Get Price Quote

We are offering spices packing machine. suited for filling food, pharmaceutical chemicals, agricultural chemicals. 35 - 65 angle of repose or particle allowed break, and other non-free flowing powders. features: servo motor - yaskawa/delta mitsubishi. touch screen - delta employs german photocell sensor for accurate control of bag length. employs japanese thermostat for fast heating and superior performance. the parts through which powders flow are manufactured from stainless or teflon, conform to sanitation standards. auger meter filling. Packaging weight is steady. specifications: model setpack-4001/a bag shaper pillow-seal film width 200 - 450 mm bag width 100 - 225 mm bag length 100 - 290 mm filling range 10 - 2000 grams filling speed 5 - 30 bags/min accuracy ± 1 - 2 % power source ac 220v 380v, 50/60hz, 3 phase power consumption 3 hp, 1.125 kw machine dimensions 1200x1100x2700mm machine weight 780 kgs

jig fixture

Get Price Quote

industrial jig fixtures

10,000 Per Piece

Tube Light

Get Price Quote

Features: Input Voltage: 90V TO 280V AC Power: 9W (2Ft), 18W (4Ft) Power Factor: > 0.90 Life Span: 50,000 Hrs CRI: > 80 Efficiency: > 120Lm/W Colour Temp: (2700K to 6500K) RoHS Compliant UV Free

Spices Packing Machine

Get Price Quote

We are listed amidst the emerging Suppliers of Spices Packing Machine and have been serving markets with the premium products. With characteristics like unmatched standard and superior grade, our range of product is the finest one obtainable in Delhi(India).

Cutting Machine

100,000 Per Units

1 Units (MOQ)

Tensile Testing Machine

Get Price Quote

Tensile Testing Machine Computerised is a consistent tool that helps the manufacturer in testing the breaking, tensile and compression strength of various materials, components and finished products. It is based on the principle of Constant rate of extension (CRE). PRESTO Tensile Testing Machine Computerised is manufactured under various test standards such as ASTM D412, ASTM D429-73, ASTM D624, ATM D638-01, ASTM D76, IS 13360-5-7, IS 3400(Part1-1987).

receiving gauge

Get Price Quote

We offer our clients precisely fabricated range of receiving gauge that comes in combination with welding fixtures. This combination is widely used in various welding process across different industries. The receiving gauge offered by us is known for its features like robustness, consistency and efficient performance.

Paper Cup Making Machine

750,000 Per Piece

Shot Blasting Machine

Get Price Quote

Rice Mill Machine

Get Price Quote

We are one of the leading manufacturers and exporters of excellent quality Length Grader. Commonly used in rice mills, the offered grader consists of rotating cylinders with cavities with screw conveyor and catch trough. This machine is manufactured using premium grade components under the strict guidance of our seasoned experts. Our quality controllers assure a flawless product delivery by testing it on various parameters. Offered RiceGrain Length Grader is available in varied specifications according to the clients’ needs at an economical price range.

Pneumatic Fixture

Get Price Quote

We our Hydraulic Fixture. Our strong design background and process expertise in the field of automation & hydraulic control helps us in successfully meeting the demands of hydraulic fixture manufacturing & hydraulic system implementation. Made from high grade steel alloy they are thoroughly tested on their tensile capsity, anti rust characteristics and durability features that keep them functional under prolonged and rough use.

Stainless Steel CNC Turning Fixture

22,000 Per Unit

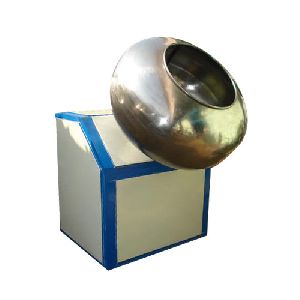

Coating Pan Machine

Get Price Quote

Quality range of Coating Pan Machine is provided by us to our esteemed clients. It has high functionality and has been manufactured under closely examined conditions. Our quality experts make sure they manufacture every piece of the Coating Pan Machine with utmost precision, attention and care. Hence it works efficiently in all situations and doesn’t get depreciated in quite a long time. The quality hasn’t been compromised with; and with every successive level of manufacturing, this Coating Pan Machine has come out to be stronger and more brilliant in its application.We manufacture high quality Coating Pan Machines. The components used are of superior grade, resulting into less wear and tear. Our clients have been using this machine for quite some time now and all of them are contented with the results. Various parameters are checked at every level before the Coating Pan Machine is being dispatched. There are many reasons, and not one behind the success of this machine. The high quality of the components which are used in the manufacture of this Coating Pan Machine makes it unique, boosting its performance to many times. More utilization can be done with less input. High standard coating material is used which gives the product an individuality. Systemized fabricated structure is used for designing of the machine. The machine is simple to use and easy to clean. It makes the machine easy to handle. The polishing pan is easy to replace and easy to maintain as well. All the parameters involved in the manufacturing process are strictly attended. The quality of the machine is never compromised with. Features High quality material used Efficient machine Best performance Less depreciation Solid surface

Jig Fixtures

Get Price Quote

A high quality range of Jig Fixtures is made available by us for our valued clients. Our Jig Fixtures are excessively used in electrical industry. Manufactured using high grade iron and steel, our Jig Fixtures assures excellent properties like sturdiness and high durability. We further make our Jig Fixtures available in various specifications to cater our client�s needs more specifically. Attributes : Dimensionally accurateExcellently designedSuperior quality

Shot Blasting Machine

Get Price Quote

Shot Blasting is the process of cleaning a surface such as iron, steel, cast-iron parts, forgings, rusted pipes, iron bars, engine and automotive parts by blasting abrasive material such as steel shots or steel grits at very high velocity utilizing the centrifugal force generated by high speed rotating disk in a shot blasting machine.Shot blasting is also used to alter the mechanical properties or various components, increasing resistance to fatigue for springs, gears, etc. Compared to sandblasting process shot blasting does not produces large amounts of dust and is much more environment friendly. A shot blasting machine is like a closed chamber so the dust particles generated at the time of blasting process remain inside the chamber and does not pollute the environment. Shot Blasting Machine is used in almost every industry that works with metal components: Ship Building and Ship Yards Aerospace and Aircraft Maintenance Iron Castings and Other Metal Foundry Forgings Rail Car and Bus Painting Alloy Wheels Cleaning Shot blasting is also used to clean floors, roads and outer walls at construction sites. Other applications of shot blasting include cleaning of under water pipes and tanks before coating or re-coating them to prevent corrosion. When we talk about shot blasting then it is important to remember that we are referring to a shot blasting machine which works by directly converting electric motor energy into kinetic abrasive energy by rotating a centrifugal wheel at a minimum of 60 kg per minute which can go upto 1200 kg per minute. With such high amounts of accelerated abrasive a shot blasting machine is used to derust, descal, deburr, desand or clean large metal parts or surfaces that cannot be cleaned effectively through other traditional or manual processes. Difference between shot blasting and sandblasting is simple to understand. In sandblasting compressed air is used to propel the abrasive towards the surface that needs to be cleaned and in shot blasting a centrifugal wheel is used to propel the abrasive toward the surface using an electric motor. Advantages of Shot Blasting: Shot Blasting is inexpensive and time saving and also abrasive material is reusable which makes shot blasting extremely affordable. Cleans and smoothens a metal surface without any damage to the surface. Economical to use and environment friendly as it does not produces very less amounts of dust compared to sandblasting. Prepares a surface for coating or re-coating applications effectively. Smoothens a rough surface and roughens a smooth surface effectively. Flexibility of using various types of abrasive materials that can be used in a shot blasting machine depending on the surface that needs to be cleaned such as glass beads, steel shots, steel grit etc. makes shot blasting the most preferred method of cleaning or preparing different metal surfaces and components. Factors that affect the Shot Blasting process and its effectiveness: Condition of the surface or the metal part that needs to be cleaned and the contaminants deposited on the surface that need to be removed. Velocity and the abrasive used to treat the surface. Working Condition of the shot blasting machine. Size of the abrasive. Hardness of the abrasive material. Level of humidity and temperature as exposure of metal surface to the environment makes it susceptible to oxidation. Maan Global Industries has mastered the process shot blasting for effective results in various industries from castings to forgings to fabrication to coatings. We are among the leading manufacturers of Shot Blasting Machines in India for over a decade and provide various models of shot blasting machines for different applications such as Portable Sandblaster, Tumb Type Shot Blasting Machine, Cabinet Type shot blasting machine, SpinnerHanger Type Shot Blasting Machine and many other models.

jig fixture

35,000 Per Piece

holding fixtures

Get Price Quote

holding fixtures, Tungsten Carbide Dies, BOX DIE, pneumatic fixtures

receiving gauge

Get Price Quote

Laser Marking, Laser Engraving, pneumatic fixtures, Die Punches