Wrangler Thar 4x4 Grill

Fuel Type : Diesel

Material : Fiber

Color : Black

Vehicle Type : Car

...more

Vacuum Assisted Resin Transfer Mold

Vacuum-assisted resin transfer molding (VARTM) refers to a variety of related processes that represent a still fastest-growing molding technology. The salient difference between VARTM-type processes and RTM is that in VARTM, resin is drawn into a preform through use of a vacuum only, rather than pumped in under pressure. VARTM does not require high heat or pressure. For that reason, VARTM operates with low-cost tooling, making it possible to inexpensively produce large, complex parts in one shot.

Application : For Molding Injections

Weight : 100-1000kg, 1000-2000kg

Color : Green

Voltage : 380V

Automatic Grade : Automatic

Power : 1-3kw

...more

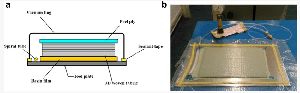

Resin Film

Resin film infusion The resin film infusion process has been identified as a cost-effective fabrication technique for producing damage tolerant textile composites. Dry textile preforms are resin impregnated, consolidated and cured in a single step eliminating costly prepreg tape manufacture and ply-by-ply layup. The large number of material properties and processing parameters that must be specified and controlled during resin infiltration and cure of textile composites make trial-and-error procedures of determining the processing cycle extremely inefficient. Analytical and numerical models are clearly far superior alternatives for determination of optimum processing cycles.

Density : 1.25 g/cm3 (@ 230C)

Thickness : 12

Density : 0.925 g/m3

Pattern : Plain

...more

Reaction Injection Mold

Reaction Injection Molding (RIM) injects a rapid-cure resin and a catalyst into the mold in two separate streams. Mixing, and the resulting chemical reaction, occur in the mold instead of in a dispensing head. Automotive industry suppliers have combined structural RIM (SRIM) with rapid preforming methods to fabricate structural parts that don’t require a Class A finish. Programmable robots have become a common means to spray a chopped fiberglass/binder combination onto a vacuum-equipped preform screen or mold. Robotic sprayup can be directed to control fiber orientation. A related technology, dry fiber placement, combines stitched preforms and RTM. Fiber volumes of up to 68% are possible, and automated controls ensure low voids and consistent preform reproduction, without the need for trimming.

Type : Injection Mould

Application : Molding Injections

Automatic Grade : Automatic

Power : 1-3kw

Driven Type : Electric

Warranty : 1year

...more

Mahindra Thar Spoiler

Material : Fiber

Deck : Single

Material : FRP

...more

Mahindra Thar Side Door Rearview Mirror Cover

Material : Glass, Plastic

Feature : Easy To Clean, Auto Adjustable

Body Color : Black

Mirror Type : Side View

Automation Grade : Auto Adjustable

...more

Mahindra Thar Bonnet

Thickness : 5 To 16 Mm

Material : Aluminium

Technique : Hot Rolled

Surface Finish : Paint Coated

Application : Automobile Industry

Features : Easy operation, High performance, Precise sizes

...more

Mahindra Thar Black Roof Wrap

Size : 0.914 x 50m

Mahindra Thar AC Vent

Material : Rubber

Application : Industrial Use

Power Source : DC Electricity

Voltage : 12 V

Packaging Type : 1 U Diffuser + 1 U Refill

Packaging Type : Box

...more

Mahindra Thar 4x4 Snorkel

Finishing : Powder Coated

Material : Plastic

Application : Automobile Industry

Vehicle Type : 4-Wheeler

Thickness : 5 mm

Warranty : 1 Year

...more

Mahindra Bonnet Scoop

Material : FRP

ISUZU D-Max Vcross Dummy Snorkel

Thickness : 5 mm

Material : Steel

Vehicle Type : 4-Wheeler

Color : Black

Application : Automobile Industry

Finishing : Powder Coated

...more

ISUZU D-Max Vcross D'box

ISUZU D-Max Vcross Bonnet Scoop

Insect Mesh Thar 4x4 Grill

Thickness : 0-10mm

Length : 3ft, 4ft

Appearance : Modern

Finishing : Polished

Feature : Fine Finished

...more

GYPSY Front Grill

Weight : 4.2 Kgs

Material : Mild Steel

Color : Black

...more

GYPSY 4 Inch Wheel Arches

Material : Carbon Fiber

Thickness : 6 mm

Color : Black

Application : Automobile

Application : Thar Vehicle Wheel Arches

Warranty : 2 Years

...more

Gladiator Thar 4x4 Grill

Vehicle Type : Car

Color : Black

Material : Fiber

Position : Front

Application : Off Road

...more

frp portable toilet

A FRP toilet collects human excreta in a holding tank and uses chemicals to minimize odors. These toilets are usually, but not always, self-contained and movable. A chemical toilet is structured around a relatively small tank, which needs to be emptied frequently. It is not connected to a hole in the ground (like a pit latrine), nor to a septic tank, nor is it plumbed into a municipal system leading to a sewage treatment plant. When the tank is emptied, the contents are usually pumped into a sanitary sewer or directly to a treatment plant.The portable toilets used on construction sites and at large gatherings such as music festivals are well-known types of chemical toilet. As they are usually used for short periods and because of their high prices, they are mostly rented rather than bought, often including servicing and cleaning.Aircraft lavatories and passenger train toilets were in the past often designed as FRP toilets but are nowadays more likely to be vacuum toilets.

Material : FRP

Application : Domestic Use, Toilet

Color : Blue

Feature : Non Breakable Durable, Eco Friendly

Built Type : Prefab,Modular

...more

FRP Benches

Public, school, office etc benches. We can make any type of products in FRP based on type of products and quantity required, also we are very flexible with the rates. Please dont go on the list we are the service providers and provide all types types of services in fiberglass carbon fiber including all types of methods starting from hand layup to RTM and vacuum bagging and vacuum infusion.

Material : FRP and Mild Steel

Size : 1200/1500/1800 mm

Appearance : Modern

...more

Angry Bird Thar 4x4 Grill

Color : Black

Material : Fiber

6 Inch Mahindra Thar 4x4 Wheel Arches

Vehicle Type : Four Wheeler

Finishing : Polished

Color : Black

Material : FRP

Packaging Type : Packet

Packaging Size : 4 Piece

...more

4 Inch Mahindra Thar 4x4 Wheel Arches

Application : Garage

Material : Frp (fibre)

Finishing : Polished

Vehicle Type : Four Wheeler

Packaging Type : Packet

Application : Automobile

...more

vintage motorcycle parts

Vacuum Infusion Process Guide Services

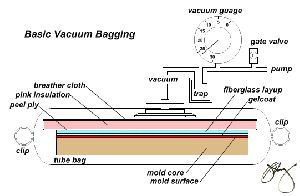

The Vacuum Infusion Process (VIP) is a technique that makes use of vacuum pressure to drive resin into a laminate. The process uses mold to hold the dry materials and vacuum is applied to it before resin is introduced. At complete vacuum, resin get dissolved into the laminate via carefully placed tubing. This process is supplemented by an array of supplies and materials. In a typical hand lay-up, reinforcements are put into a mold and manually wet out using rollers, brushes, or through other means. In order to suck excess resin out of the laminate, vacuum bag is used. Vacuum bagging is useful to improve the fiber-to-resin ratio, and results in a stronger and lighter product. If you are unfamiliar with vacuum bagging, we recommend you our vacuum guide that entails vacuum bagging equipment and techniques for room-temperature applications. For any other query or discussion, one can approach us anytime.

...more

Vacuum Bag Moulding Services

MOTOMAX INC is a known name, involved in providing vacuum bag molding services from Faridabad (Haryana, India). With our services, we use a flexible film to enclose the part and insulate it from outside air. The material that we use is in a tube shape or a sheet of material. When a tube shaped bag is used, the complete part is enclosed within the bag. And, when sheet bagging materials is used, the edges of the vacuum bag are wrapped against the edges of the mould surface to surround the part against an air-tight mould. This way, the lower mold gets a rigid structure and the upper surface of the part is made by the flexible membrane vacuum bag. We use a reusable silicone material or an extruded polymer film as a flexible membrane. This part is sealed inside the vacuum bag and vacuum is drawn on the part (and held) during cure.We perform these operations either at ambient or elevated temperature with ambient atmospheric pressure acting upon the vacuum bag. Besides, we use a vacuum pump draw a vacuum. Using venturi vacuum and air compressor is considered as an economical method of drawing a vacuum. The bag that we mold is made of strong rubber-coated fabric or a polymer film. With our bag molding services, we cater to ever-changing demands of the clients across composites sector. Carbon fibre fabric and fibreglass, along with resins & epoxies are the common materials that are laminated together with a vacuum bag operation. So, to schedule an appointment, ring us on the given numbers.

...more

RTM / LRTM Resin Transfer Molding Services

The internal surfaces of mold may be gel-coated. If required the mold can be pre-loaded with a preform. The maximum volume of the fiber content of a transfer molded composite can be 60%. The material that used for filling may be a preheated solid or a liquid. This filling material is loaded into a chamber known as the pot. A ram or plunger is used to move the material from the pot into the heated mold cavity. If feed-stock is initially solid, we apply forcing pressure and mold temperature to melt it. Besides, we make use of standard mold features such as sprue channels, a flow gate and ejector pins for the ease of molding. We use heated mold to ensure that the flow remains liquid for complete filling. Once filled, we put the mold to cool down at a controlled rate for optimal thermoset curing. With our RTM / LRTM resin transfer molding services, we use a liquid thermoset resin to saturate a fiber preform placed in a closed mold. The process that we use is versatile and can be used to fabricate products with embedded objects such as foam cores or other components in addition to the fiber preform. So, contact us anytime for a detailed discussion.

...more

Fiberglass Molding Services

Every fiberglass molding operation starts with the usage of an object that is called a buck or a plug, made using a certain type of foam. This buck is nothing but a replica of the final object that would be made after the fiberglass molding. Once we have made the plug, our experts spray it with a mold release agent, a typical kind of wax, and/or PVA (Polyvinyl alcohol, to ensure that the final object is easily separated post the completion of the molding process. After putting this mold release agent, we use a roller, brush, or a spray gun to apply a gel coat on the plug. This gel coating is usually a kind of pigmented resin to give a durable and harder finish to the mold’s surface. After we have successfully applied both the mold release agent and the gel coat, we cover the plug’s surface with different layers of resin and fiberglass. In this process, we make use of a fiberglass that resembles the final product in mind. The next step is called the laying-up process. In this step, we add a layer of fiberglass mat on the surface, over which, we apply a layer of resin. To ensure there are no air bubbles on the surface, we use a special kind of roller to remove any bubbles that might have been left while curing the resin. If air bubbles are not removed, it might reduce the strength of the final finished mold. Once this is done, we move on to the fiberglass spray lay-up process. This process is also very beneficial in producing molds as it is very effective in filling up the cavities and corners where the weave or glass mat might have proven to be stiff to reach. Once all this is done and we have covered the mold with the final layer of fiberglass, we let it rest for some time to ensure the resin is cured and properly set up. Lastly, we take separate the plug from the mold using special wedges. For this separation, we might also incorporate various advanced techniques like resin transfer molding. If you are also looking for expert-level fiberglass molding services, MOTOMAX INC is the name you should bank upon.

...more

Carbon Fiber Moulding Services

Incorporated in 2017, MOTOMAX INC has been operating as a single window solution provider for carbon fiber moulding operations. The company is based in Faridabad (Haryana, India) and we provide standard and tailored solutions to satisfy the emerging demands of the clients.Process: The tail of a radio-controlled helicopter that is made of CFRPrn carbon fiber reinforced polymer or carbon fiber reinforced thermoplastic is an extremely strong and light fiber-reinforced plastic that contains carbon fibers. CFRPs can be expensive to produce but are widely used in applications where high strength-to-weight ratio and stiffness (rigidity) is required such as - aerospace, automotive, superstructure of ships, sports equipment, civil engineering, and an increasing number of consumer and technical applications. We majorly use thermoset resin such as epoxy as a binding polymer; other thermoset or thermoplastic polymers we use are polyester, vinyl ester, or nylon. In addition to carbon fibers, the composite material may comprise aramid (e.g. Kevlar, Twaron), ultra-high-molecular-weight polyethylene (UHMWPE), aluminium, or glass fibers. The properties of the final CFRP product may vary depending upon the type of additives introduced to the binding matrix (resin). We use additive like silica, rubber and carbon nanotubes. Clients are free to share specific details. So, get associated with us and avail the benefits of simplified solutions.

...moreOpening Hours

Motomax INC is a prominent name in the service sector of Faridabad. We are offering the best services to the clients at the most affordable charges. Our list of services includes fiberglass molding services, carbon fiber moulding services, vacuum bag moulding services, RTM/ LRTM resin transfer molding services and vacuum infusion process guide services. For rendering these services, we have hired a reliable team of deft professionals, who hold an extensive experience of working in this domain. These professionals make use of the best techniques which they have learned in their basic training to render these services as per the clients’ requirements and as per the set industry standards. All the services that we make available can be availed at market leading charges from us.

Located in Faridabad (Haryana, India), Motomax INC is operating in the industry since 2017. The company has emerged as one of the most notable names in the service sector of Faridabad by offering the superior class services.

Our Clientele

The services offered by us are widely availed by many clients in Faridabad. Many moulding related industries are our regular clients in Faridabad. Moreover, not just in Haryana and India, our services are widely availed by many clients all over the world.

Why Choose Us?

Working in the industry since 2017, the company has become the top choice of the clients to avail various moulding services at reasonable charges. Moreover, the company has gained a sizeable clientele all over the world for rendering the best services.