Edible Oil Refinery Plant

10,000 - 1,000,000 Per Piece

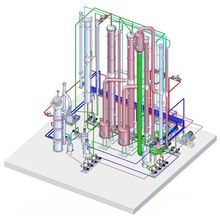

Edible Oil Refinery Plant that we provide is extensively used for refining the crude oil in order to make it pure and edible. Our Edible Oil Refinery Plant is especially designed for providing minimum operation costs and maximum output results. Edible Oil Refinery Plant is appreciated for its sturdy construction, low maintenance and high functionality. Our refinery can refine almost all types of oils but the quality of the refined oil will depend upon the type of crude oil and its chemical structure. Vegetable oil is properly refined for complete removal of waxes, gums (phosphatides) and free fatty acid. After refining, the oil is filtered from various impurities, odor and viscous pigments, thus gets a uniform color. In the plant, there can be batch refining or continuous refining as per the requirement of the applications. Incorporated with latest technology, the vegetable oil refining plant is specially designed with different processes, all integrated in a single compact unit. The plant is assembled with a bleacher, neutralizer, heat exchanger, and deodorizer, filters and high & low vacuum equipments. We are the forerunner in the industry for introducing advanced distillative deacidification technique (physical refining) in the vegetable oil refining. This is an innovative technique introduced that has the capability to totally eliminate the caustic treatment with all its attendant disadvantages. We also hold expertise in manufacturing pressure leaf filtration system that is specially engineered for flow rates. Available With Neutralizer Bleacher Deodourizer Cooler Thermic Fluid Boiler Filter Press Filter Press Raw Oil Tank Bleach Oil Tank Soap Pan Soap Pan Features Energy efficient operation Optimum consumption of chemicals Continuous operation with automatic loading Desolventiser toaster is used as a standard equipment Integration with advanced process control system and efficient plant performance Ensure high flow rate Wet bleaching for lower earth cost Consistent product quality and output

oil refineries

Get Price Quote

The effluent from the Oil Refineries and Electroplating Industries is generally low in solids content and contains metals like chromium and manganese.The effluent is preheated and then fed to the Multiple Effect Falling Film Evaporator for concentration. After concentration, the concentrate is dried using an Agitated Thin Film Dryer. This dried powder can be disposed of as solid waste for land fill. The condensate obtained from the evaporator is clean and colourless which can be used in the plant as process water.

Best Deals from Oil Refinery Plant

oil refineries

Get Price Quote

oil refineries, Fruit Juices, vegetable juice, oil mills