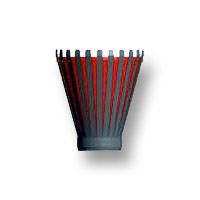

Zinc Spiral Blade (Vane) Centralizer

We fabricate Zinc Spiral Vane Solid Rigid Centralizer are designed from our experts and provides efficient functionality. These are checked on a regular basis and that are used in different industrial applications. The offered zinc spiral vane solid rigid centralizers are simple and convenient, extensively used for rough and fine polishing of metallurgical specimens. They are available at cost effective price. This gentle flow from the body to the height of the vane will eliminate scraping, gouging or digging into the formation and consequently reduce balling between the vanes.

...more

Wire Scratcher OM

This comprises of a hinged collar and wire bristles are attached to it. It uses the hinge pins to secure the collars around the casing. On the other hand, the wire bristles are hardened and tempered. The bonding of the cement between the porous formation and the casing is improved with the use of wire scratcher.

...more

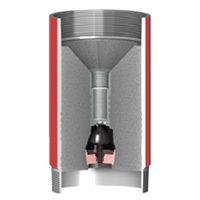

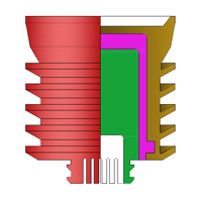

Steel Spiral Blade (Vane) centralizer OMS

OILMEC Spiral Solid Centralizers are constructed of one-piece high strength corrosion resistance Alloy Aluminum, Alloy Steel, Stainless Steel or Non sparkling Alloy Zinc. Centralizers are available in short length, long length and standard length. Further, they can supply fixed design and non-fixed design. These Centralizer are High graded castings followed with surface finishing on CNC Lathe, then rigid inspection make a quality product. All Centralizers are stove painted or coated with polyester powder. They are available in all sizes ranging from 3 ½” to 13 38” for any hole combination.

...more

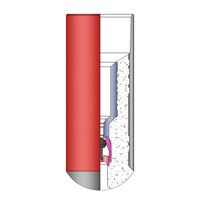

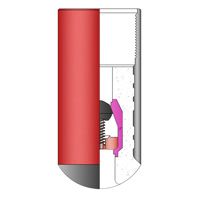

Stab In Latch In Float Shoe

Stab in latch in Float ShoeOilmec Stab in Latch in Float Shoe receptacle has ratcheting left hand threads to lock the stinger into the float Equipment. Dril pipe and stinger can be easily backed out of the Float equipment receptacle when cement job is complete. Recommended where reciprocation of the casing is required. Oilmec’s Stab in Latch in Float Shoe is PDC Drillable

...more

Stab In Latch In Float Collar

Stab In Latch In Float CollarOilmec Stab in Latch in Float Collar receptacle has ratcheting left hand threads to lock the stinger into the float Equipment. Dril pipe and stinger can be easily backed out of the Float equipment receptacle when cement job is complete. Recommended where reciprocation of the casing is required. Oilmec’s Stab in Latch in Float Collar is PDC Drillable

...more

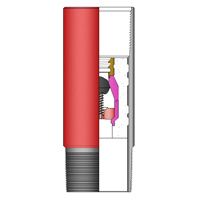

Stab in Float Shoe OM

With Stab-In cementing, the drill pipe is stabbed directly into the float shoe or collar and cement is pumped through the drill pipe until returns reach surface. Cement is then displaced to the bottom of the drill pipe – a wiper dart can be used. The drill pipe is then picked up, circulated, and pulled out of the hole.

Feature : Seal reliable and high pressure resistance,Withstand long periods of circulation,Easy drill out with PDC or roller-cone bits

...more

Stab in Float Collar OM

Oilmecs Stab-in Float Collars are provided with stab in profile for stab in cementing where the drill pipe stabbed directly in to the float collar. Stab in cementing is an improved method for cementing large diameter casing. Conventional method required excessive amounts of cement to ensure cement circulation to surface because of open hole volume, losses to the formation, or mud displacement efficiency that cannot be determined with sufficient accuracy.

...more

Slip on Welded Semi-rigid Centralizer

Oilmecs Welded Slip On Semi Rigid Centralizer having the same Features and Characteristics as the Hinged Welded Centralizers. Collars are specially designed with roll formed peripheral ridges which provide extra rigidity. Slips On Centralizers are provided for direct installation on pipe by slipping on and can be provided with Set Screw for elimination of Stop collar. These centralizers undergo a special Iron Phosphate coating process to prevent from Rust then coated with special Polyester Powder they are available in all sizes ranging from 4 ½ “ to 20 ”.

...more

Slip on Welded Positive Spirolizer

Oilmec Slip on-Welded Positive Spiralizor, is designed specifically for highly deviated or horizontal wells. The steel construction ensures extra strength and superior toughness. The design of the blades provide minimum friction reducing drag forces while running in the pipe. The Spiralizor are available in spiral and straight blades which resist high side loads. While giving maximum standoff the blades create vortex flow to optimize mud displacement. The centralizers are available from 3 ½” to 13 38”.

...more

Slip on Welded Heavy Duty Straight Bow Spirolizer

Oilmecs Slip on Heavy Duty Welded Straight spiralizor is specially designed for Horizontal wells and highly deviated. The heavy steel construction is highly effective as compare to other alloy. Wide symmetrical Straight fins are welded to the one piece rolled formed Sleeve under required temperature and condition with extra low Hydrogen coated Electrodes, which assured ultimate strength and uniformity in every weld. Steel construction provides superior toughness over other materials. Vanes can be selectedto meet any hole. Straight Slip On Welded Spiralizor are provided for direct installation on the pipe by slipping on and can be provided with compatible Stop Collars beveled from one side positioned by set screw. These centralizers undergo a special Phosphate coating process to prevent from Rust then coated with special Polyester Powder they are available in all sizes ranging from 3 12″ to 13 38″.

...more

Slip on Welded cement basket

Cement Basket is an effective aid in retaining and supporting the cement where weak formations and stage cementing is encountered. It is designed with Flexible Bow Springs, heat-treated under controlled conditions for maximum strength and uniformity, are welded to slip-on collars and overlapping metal fins for flexibility and strength to support long columns of cement during primary cementing operations.

...more

Slip on Stand off Band Centralizers OMSOS

Slip On Stand Off Band rigid centralizer is designed to provide a positive stand off the casing for both cased and open holes. The angled fins provide increased turbulent flow. These Slip On Stand Off Band is require where close tolerance between the casing and the hole is being encountered. Mainly it’s designed for the liner applications. Design of the stand off Band allows for reciprocation and rotation during cementing and can be installed between Set Screw Stop Collar These Stand Off Band undergo a special Phosphate coating process to prevent from Rust then coated with special Polyester Powder. These are available in all sizes ranging from 3 12″ to 20″.

...more

Slip on set Screw Stop Collar OMSC

Slip on Set Screw Stop Collar is of one piece high strength corrosion resistant alloy collar and the gripping force is applied by one row of Set Screws. The outside ends of these collar are generally tapered to a degree which helps to hold the centralizer and avoid the ends to hit the Bows Vanes when the centralizers are placed over them.

...more

Slip screw Stainless Steel Stop Collar

The Slip on Set Screw Stop Collar is a single piece collar and the gripping force is applied by one row of setscrew. It is used where high axial load tighten the collar to the casing tightly. They slid the casing pipe without any issue and it is quite easy to install. These are most effective where low annual clearance is chanced upon. The stop collars come with a special Phosphate coating process that prevent it from getting rust and come in ranges starting from 4 12 � to 20 �.

...more

Slip on canvas Cement Basket OM

This cement basket consists of a slip-on style made of high strength, flexible steel staves that are mounted on a steel slip-on ring with heavy duty canvas liners riveted to staves fabricated of high strength, flexible steel bows mounted on a steel slip-on end collar. This cement basket is typically installed between (2) stop collars. This cement basket has a better ability to conform to the bore hole and can accommodate larger than nominal hole sizes. Sizes are available for all standard casing hole sizes. Recommended for use with all standard casing grades.

...more

Rotating Welded Centralizers

Oilmecs Rotating Centralizers were developed for the requirement of Centralizers that could be used with a rotating liner in highly deviated well conditions. These Centralizers are specifically designed to meet or even exceed the API 10 D Specs so as to have high restoring force which provides optimum stand-off and low moving force to minimize drag. These Centralizers allow free rotation of the pipe for maximum displacement efficiency. Casewell provides these Centralizers with ‘stop collar inside’ design so as to minimize moving forces while reciprocating

...more

Rotating Spiral Blade OMRS

OILMEC Rotating Solid Centralizers are constructed of one-piece high strength Stainless Steel or Alloy Steel. Centralizers are available in standard length only. These Centralizer are High graded castings followed with surface finishing on CNC machines, then rigid inspection make a quality product. All Centralizers are stove painted or coated with polyester powder. They are available from 3 ½” to 13 38” for any hole combination.

...more

Reamer Shoe OM

Oilmecs Reamer Shoe is designed specifically to be installed on Casing or Liner and Screen where operators have concerns about potentially difficult wellbore conditions such as, swelling shale’s, ledges and washed out areas of wellbore, post drilling and prior to running casing. The aluminium eccentric guide nose climbs ledges and negotiates obstructions while the cutting structure reams out tight spots or obstruction in the wellbore. Compatible with all casing and liner hanger assemblies, our Reamer Shoe provides highly effective protection- against unexpected or anticipated casing and liner running problems, and has been specifically designed for potentially difficult wellbore conditions such as swelling shales, ledges and washed out areas of wellbore. The high strength profiled alloy nose will anchor even in uncured cement to facilitate ease of drill out. The aluminium eccentric nose is easily drilled with both PDC and Rock bits. The chip breaker holes in the nose assembly are designed to create small aluminium chips to avoid “bird nesting” on the bit. Benefits to customers include improved drillout times without compromising the reaming capabilities, a reduction in NPT and increased opportunities to reach TD.

...more

Polyamide Spiral Blade Solid Rigid Centralizer

Thermoplastic Solid Rigid Centralizers are made of special engineered polymer material to meet the various well conditions. This material has high abrasion resistance for maximum stand off and can withstand in wells having temperature upto 400° F temperature. It has low coefficient of friction and ultimate drag forces for performing excellent in deviated and horizontal wells. These centralizers are impact resistive having optimum tensile and yield strength. The Vanes of these centralizers are designed to have improved hole cleaning by filter mud cake removal and enhanced localized turbulence for improved cementing. These centralizers are provided with swage rings at both its ends to enhance strength. Straight or Spiral vanes are available for various requirements. These centralizers are also available with set screws to make it rotation free.

...more

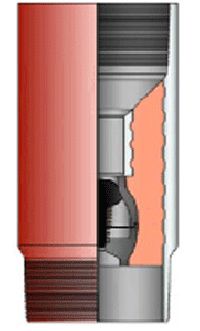

conventional Float Shoe OM

A rounded profile float shoe with an integral check valve attached to the bottom of a casing string prevents reverse flow, or U-tubing, of cement slurry from the annulus into the casing or flow of wellbore fluids into the casing string as it is run. The float shoe also guides the casing toward the center of the hole to minimize hitting rock ledges or washouts as the casing is run into the wellbore. By �floating� casing in, hook weight is reduced. With controlled or partial fill-up as the string is run, the casing string can be floated into position, precluding the need for the rig to carry the entire weight of the casing string. The outer portions of the float shoe are made of steel and generally match the casing size and threads, although not necessarily the casing grade. The inside (including the external taper) is usually made of cement or thermoplastic, since this material must be drilled out if the well is to be deepened beyond the casing point.

...more

Oilmec Lok ll Thread Lock OM LOK

Oilmec Lok is the next generation cementing product in the thread compound technology and design. Just like the oil filled pipe materials and connections are masterminded as per the specific application and field services requirement. The thread compounds must be formed to meet the vital execution requirement.

...more

Non-Rotating Top Cementing Plug

The Cementing Plugs manufactured in our company include top plugs and bottom plugs.These plugs offer the following advantages: Special non-rotational device design allowing the plugs to drill out quickly Special materials designed for easy drill out with PDC bits High-heat and high-pressure resistance

...more

Non-Rotating Float Shoe OM

The Non-rotating Float Collar is attached to the end of the casing string and they are used to stop slurry from flowing back. Material inside is easily drillable; the anti-rotation mechanism on the top improves drill-out performance. The valve consists of rubber and polymer materials with high tensile strength. Single or double valves are available. However non-rotating Float Shoe is not required if you are asking for Non-rotating float Collar. But it is provided on customer demand

...more

Non-Rotating Float Collar OM

The Non-rotating Float Collar is attached to the end of the casing string and they are used to stop slurry from flowing back. Material inside is easily drillable; the anti-rotation mechanism on the top improves drill-out performance. The valve consists of rubber and polymer materials with high tensile strength. Single or double valves are available

...moreBe first to Rate

Rate This