CNC Insulation Paper Inserting Machine

Get Price Quote

1 Piece (MOQ)

Details We manufacture and supply extremely cheap and best insulation paper inserting machine. This machine is specially designed for insulation paper of ceiling fan motor staror. All procedure actions are done by the machine automatically except to put on and take off stator. The production cost will be highly reduced by decreasing the material loss labor cost. Controllers Features The complete inserting time for 16 poles stator can be shortened to 8sec/stator. High insertion speed is about 0.5 sec/slot for labor saving, cost reduction, and stable qulaity output. Easy adjustment while changing stack height of stator or width of insulating paper. Change tooling design to meet different shape of stator slots.

Roll Fed Square Bottom Paper Bag Making Machine

Get Price Quote

1 Unit (MOQ)

Best Deals from Paper Machines

Super Fold Paper Folding Machine

Get Price Quote

1 Piece (MOQ)

The Super Folder Paper Folding Machine is a high-grade automatic machine that is perfect for businesses that require a large volume of paper folding. This machine is made of mild steel and comes in a beautiful blue color. The computerized system ensures precise and efficient folding, making it an ideal investment for businesses that require high-quality output. The machines automatic grade makes it easy to use, and it comes with a warranty to provide you with peace of mind.

PW01 CNC Ceiling Fan Paper Inserting Machine

Get Price Quote

1 Piece (MOQ)

Description : This Machine is suitable for ceiling fan stators. Automatic Process, excluding loading and unloading. Fast speed and good quality. Suitable many kinds of models with different Slot Die. Folding width of insulation papers can be adjusted.

Tea Bag Machine With Paper Crimping Envelope

Get Price Quote

PIV Gear Box Paper Cutting Machine

150,000 - 250,000 Per Piece

1 Piece(s) (MOQ)

Our prime concern is to fulfill variegated requirements of the clients, all the time. And, to achieve this objective, we have installed a capacious warehouse. Owing to our huge logistics network, timely delivery of the placed orders is always executed!

Thermal Paper Slitting Machine

Get Price Quote

1 Set (MOQ)

Manual Creasing Machine

8,000 - 9,500 Per Piece

1 Piece (MOQ)

Dot Matrix Paper Printing Machine

140,000 Per Unit

1 Unit (MOQ)

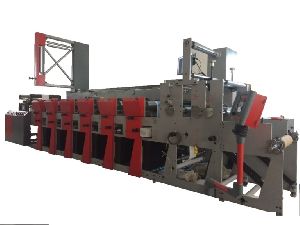

THERMAL PAPER PRINTING MACHINE

Get Price Quote

Thermal Paper Printing Machine is a narrow web flexo press for printing Thermal paper. The output comes in roll to roll. Its modular design and precise, rigid construction provide the versatility and reliability necessary for the most difficult jobs. The Flexo graphic press can be assembled to your specifications in various widths. A full range of option further enhances the versatility of the flexo press and its ability to handle a variety of applications on a broad range of materials. Thermal Paper Printing Machine is constructed to provide a superior foundation for quality printing and converting. it has full dual side frames to create a solid and rigid structure not attainable with partial frames supported on sheet metal legs or with cantilevered designs. Consistent, repeatable quality printing is facilitated by the ease of operating the machine. Precise print adjustment are made quickly, Even when changing material. Doctor Blades, Plate Cylinder, Anilox rolls can be changed quickly even after the job is set up, and the closed loop tension system provides exact and repeatable control ate the operator selected tension level. Features : 360 Registration Gear Box Web Video Inspection Energy-Saving Drying System Auto Control Temperature Of Dryer Perfect Rewinding Turnbar System Excellent Registration

Paper Bag Machine

Get Price Quote

Finetech Tissue Machine is a reputed paper converting machine manufacturers, suppliers, exporters based in India. We are offering Paper Bag Making Machine in Pune to our valuable clients. We used advanced and latest technology in our manufacturing process to meet the current requirement of the market. We manufacture and change specification as per the requirement of the clients. We commit you to deliver your consignment at your door step on time, we also provide you after sale services. Our products made by latest techniques so it need less maintenance and work for long time, do hassle free work and very easy to operate. We are offering all products at a price best in the industry. Our entire team works with complete dedication so in today’s time we are capable to win the trust of our clients. All the interested clients looking for Paper Bag Making Machine in the Pune should contact us by sending enquires. As well-known manufacturers, suppliers and exporters, we commit you to fulfill all your requirements within stipulated time period.

Paper Napkin Making Machine

400,000 - 1,000,000 Per Box

We are instrumental in offering top-notch quality Paper Napkin Making Machine also available in Multi Size. Available in specified drawings, our Paper Napkin Making Machine suits different industries engaged in napkin paper making business, be them small scale, medium scale or large scale units. Every machine consists of changeable stereo cylinder, forward and backward adjustment feature, one ink roller dipped in duct, embossing unit, one hard chrome plated design roller, one bowl paper roller, folding unit, rotary cutting system and automatic electronics counter. It is efficient in making 300 pcs of paper napkin per minute. Our Paper Napkin Making Machine is widely acclaimed for high efficiency, simple operation, low power consumption, vibration less operation, easy maintenance and exceptional durability. Specifications : Product Code : V001-X2 No. of Printing unit : As Required No. of Embossing : As Required Standard core inner diameter of parent roll : 76mm Cutting range : 230mm to 350mm Motor : 3H.P., A.C. with variable speed drive Space Required : 10' X 6' X 4' Machine Weight : 2000kg Capacity (per min.) 300 pcs per minute (depends upon paper) Minimum Fold 1/4 type Maximum paper width : 300mm/350mm Maximum unwinding Diameter : 1200mm Size Available : Multi sizes

Super Paper Folding Machine

Get Price Quote

1 Piece (MOQ)

Features : 1:2 folder capable of folding 8 webs (with double RTF roller) in broadsheet/tabloid at speed up-to 30000 cph. RTF roller, cutting cylinder and jaw cylinder dynamic balance air former. Double nipping roller Folder jam switch Single lights on the folder Main drive shafts with Thomas coupling at cylinder heights for minimum backlash and smooth power transmission Electronic copy counter Electronic good copy counter Kicker for 0-99 copies adjustable Centralized oil pressure lubrication for drive gears Slitter or perforator on RTF Grease lubrication for operating side bearings and cams Hardened and ground gears for folder drive and cylinder Lap adjustment -/+ mm

paper roll cutting machine

270,000 Per Piece

1 Piece (MOQ)

Fingerless Paper Corrugation Machine

Get Price Quote

We have come up with the highly demanded fingerless paper corrugation machines. Our fingerless paper corrugation machines are extremely efficient and demand low maintenance. We manufacture our fingerless paper corrugation machines with the use of best quality components to ensure durability and high performance. Our fingerless paper corrugation machines can be obtained at affordable prices. specifications design speed 120mt/mincorrugated roller made of ni-cr-mo-alloy steel with heat treatment (hardness 55-58 hrc)roller surface plated with chrome treatmentlower flute roll dia 320mm diaindividual gear bo- drive separating dynamic oscillating improves running stabilitythe glue application unit can be engaged and disengaged with the corrugation roll under the parallel movement of pneumatic cylindervacuum suction fingerless design provides prefect flute formation driven by heavy duty bloweradjustment of upper corrugated roll and pressure roll and glue roll controlled by pneumatic systemglue roll is duly engraved and glue dam is provided for accurate transfer of glue to the flute roll while formation of 2-plywith dam system for control of gum transfer width wisewith preheating and pre conditioning rollercirculating glue supplying system is available with the tank pump & motoravailable width 1400mm – 2500mm

Paper Bag Making Machine

Get Price Quote

Automatic Die Cutting And Creasing Machine

Get Price Quote

waste paper egg tray making machine

Get Price Quote

Tissue Paper Packaging Machine

Get Price Quote

Auger base ffs machine is one of our form fill seal machines which are manufactured with high degree of precision to handle diverse type of non free flowing powdered products (Also known as powder packing machine) like Custard Powder filling and packing, Roasted Ground Coffee, Spices, Talcum Powder packaging, Detergent Powder packing, Pharmaceutical Powders, Dyes and Coloring agents Powder, Distemper Powder, Pesticides etc. High Accuracy on this filling system is achieved due to accurate design of Auger Screw, very sophisticated clutch brake and micro processor control system. • Auger Filler can also be used as a individual filling machine for hand filling operation. • All the contact parts of auger base ffs (form fill seal) machine are made of Stainless steel (SS-304) which makes the parts corrosion resistant in addition to longer life.

Paper Cutting Machine

200,000 Per Piece

paper slitting rewinding machine

Get Price Quote

1 piece (MOQ)

A slitter rewinder is a machine dedicated to cutting a master or parent roll of material to a smaller width in order to process the material in the next steps of a production process. Slitter rewinders can be found in numerous types of manufacturing facilities in numerous types of industries across the globe. These machines are also commonly referred to as, slitters, rewind slitters, and/or roll slitters. Most slitter rewinders are built for specific types of materials but can be modified to slit multiple materials as well. In conjunction with material roll specifications, most manufacturers search for slitting machines to slit specific materials, slit using specific slitting methods, or to slit under production requirements such as operator ease-of-use/safety, floor space, and speed.

Paper Bag Making Machine

900,000 Per Piece

Collator Machine

Get Price Quote

The company is specialized in offering the finest quality Collator Machine in the national as well as international markets. Our Forms Collating Machine is manufactured from the best quality raw materials making it highly endurable and long lasting in nature. These machines are easy to operate and effective in performance. In addition to the above fact the company is counted as a leading name among the Package Collator Machine Exporters from India.

A4 Paper Cutting Machine

1,200,000 - 1,900,000 Per

Automatic Die Cutting And Creasing Machine

5,500,000 - 10,000,000 Per Set

Paper Plate Making Machine

Get Price Quote

Backed by a team of diligent professionals, we offer high quality Plate Making Machine. Our automatic Paper Plate Making Machine is a sort of environmental protection machine, widely used by the clients for making disposable paper plates. Our Paper Plate Making Machine is multiple station automatic mechanical equipment used for making single sided PE coated paper plates. The clients can avail the Paper Plate Making Machine from us at the most competitive price. Features Of Our Paper Plate Making Machine : Fully AutomaticEasy change molds to produce different plates Easy to operate Maintenance-free Paper Plate body sealing Sides by heaterbottom by hot air station

Paper Bag Lace Tipping Machine

285,000 - 370,000 Per Unit

1 Unit (MOQ)

We are the principal manufacturers of paper bag lace tipping machine in india. Manufactured using premium quality raw materials, our range are well known across the globe for the below enlisted features:

Paper Slitting Machine

200,000 Per Piece

1 Piece (MOQ)

Paper Pouch Packing Machine

175,000 - 550,000 Per piece

1 piece (MOQ)

Features such as - Machine halts when roll finishes Machine halts if heater fails and gives alarm Machine halts if eye mark misses Machine halts if material finishes

paper testing machine

Get Price Quote

Box Compression Tester – HMI is the advanced model to assess the compressive strength of the corrugated cartons. When used in real working conditions, cartons are often stacked over each other. To avoid the product failure, the boxes are prior tested for stacking load bearing capacity. The machine is designed with 2 strong columns structure for synchronized movement of the plates. The compression plates are equipped with motorized arrangement for uniform load application on the test specimen. The integration of HMI touchscreen eases the operation to a large extent. With its unique overtravel protection feature, the plates come to a halt once the sample deforms. This helps in increasing the accuracy of the test and reduces the power consumption.