Visual Flow Device

Operator can visually check the flow of cooling medium in the core pin cooling process Operator can check continuity of flow in each line Ball inside the unit moves displaying fluid movement and if any one or more ball stops moving, it indicates malfunction Designed & manufactured for number of lines which needs to be monitored

...more

Vacmax Series Vacuum System

Peripheral to evacuate airgases from mold cavity and shot sleeve during a die casting process Helps to minimize air inclusionsgas porosities in the castings Better vacuum translates into optimum quality Reliable process monitoring reduces the rejection rate Integrates to any die casting machine Low maintenance Features: Designed with twin stage vacuum process by which air is evacuated in two stages: Stage 1 in shot sleeve and stage 2 in mold cavities Inbuilt vacuum pump and vacuum tank Monitoring of vacuum with graphical displays of stages Turnkey solution to support die casting process nature and cycles Custom built filters to secure the system User friendly operations with simplified touch screen setting

...more

Tap Out Cones

Tapout cone is used in reverberatory furnace in aluminum melting It is a soft vacuum formed ceramic fiber part It is used to cover & plug tap hole plugs used in furnaces for melting for Aluminum, magnesium & zinc alloys

...more

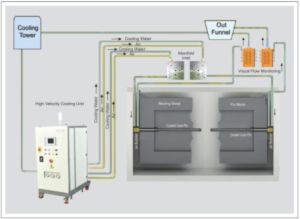

High Velocity Cooling Unit PRO Series

Peripheral to cool core pin during the die casting process Integrates to any die casting machine Injects water and air cyclically at high pressure into core pins of die casting mold Technology at affordable price Low maintenance Uses shop floor air and soft water Unit with integrated automatic water softener (optional) prevents clogging of core pins & Jet Coolers.

...more

High Velocity Cooling Unit NEX Series

Peripheral to cool core pin during the die casting process Suitable for die casting with frequent die changes Advanced equipment which ensures complete safety of both machine and operator Integratesinterface to any die casting machine Uses shop floor air and soft water Unit with integrated automatic water softener (optional) prevents clogging of core pins & Jet bubblers Optional devices like Flow sensing, Flow indicating & malfunction sensing can be integrated for early & easy detection of cooling malfunctions

...more

Core Pin Cooling

Cooling of small diameter core pin was a major challenge for die caster. The developments in the last decade have made it possible now. Advantages of Core Pin Cooling : During high pressure die casting of Aluminium alloys, generally there are three defects that are confronted by die casters on or around core pins: Soldering Shrinkage porosity around core pins Wash out Cooling of core pins results in minimization of the defects. This process also improves the life of a core pin used in casting process.

...more

Core Pin Cool Unit ECO Series

Peripheral to cool core pin during the die casting process Integrates to any die casting machine Injects water and air cyclically at high pressure into core pins of die casting mold Technology at affordable price Low maintenance Uses shop floor air and soft water Unit with integrated automatic water softener (optional) prevents clogging of core pins & Jet Coolers.

...more

pouring ladle

Shot Sleeves

Plunger Tips

intake manifold

Plunger Adapters

Plunger Rods

water jackets

Cone Bushes

Chill Vents

Pin End Cutting & Grinding Unit

Be first to Rate

Rate This