Vegetable Processing Plant Machinery

Get Price Quote

1 Set(s) (MOQ)

Tomatoes are continuously unloaded into tomato unloading and washing unit. Then tomato will be sent to washing unit where the washing takes place by means of water jet and air jet. The manual washing operation can also be takes place for small scale processing by using concrete washing tank. Washed tomatoes are then transferred to sorting table where the tomatoes (damaged rotten) that will be not accepted in the line and will be removed manually in the sorting table. The washed and graded tomatoes are then transferred to fruit crusher where tomatoes will be crushed to form the slurry. This slurry is directly put into the "hot cold break system" where it is heated to 65-700c or 950c in hot break system for the enzymatic inactivation. After this operation the slurry is transferred to pulper through suitable pump for separating the pulp and waste. The separated tomato seeds, skin and waste material is collected in a hopper and discharged through screw conveyor. Pulp obtained is called "puree". The refined tomato juice from pulper cum finisher is then fed to the double effect vacuum evaporator to be concentrated by boiling at low temperature under vacuum to preserve the organoleptic characteristics of the tomato. For batch type small scale processing this refined juice is fed to double jacketed steam kettle. Final concentrated tomato puree at 14 brix tomato paste at 30 brix coming out from evaporator kettle would be further used for pasteurization in tubular pasteurizer and cooling at 45-500c for filling in drums.

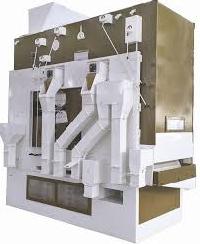

vibro cleaner

Get Price Quote

vibro cleaner, SIFTER, rice bran separator, Pre Cleaner, Length Grader

Best Deals from Seed Processing Machinery

Herbal Extractor

Get Price Quote

vibro cleaner

Get Price Quote

vibro cleaner, Destoner, GRAIN CLEANER, Paddy Cleaner, rice cleaner

grain fine-cleaner

Get Price Quote

grain fine-cleaner, Destoner, Rice length grader, Paddy Cleaner

Rubber Processing Machine

Get Price Quote

Rubber processing machine, The Steinbeis – IamSMEofIndia Centre for Technology and Innovation has envisaged the formation of a technology network connecting the Rubber Processing Industries of Faridabad with their European Counterparts. The central idea of this network and this collaboration shall be to improve, technically, up on the pain areas of Rubber Processing such as Tear – Trim, Mould Design and Development, Machine Optimization, De-flashing etc. and through this improved facility, lead to enhanced trade between India and Europe.

pet food processing machine

Get Price Quote

grain processing machinery

Get Price Quote

grain processing machinery, Rice Cleaning Machine, Wheat Cleaning Machine

Pulses Processing Machine

Get Price Quote

Pulses Processing Machine, Automatic Chilli Cleaning Machine, Rice Sifter

Plastic Processing Machinery

Get Price Quote

Plastic Processing Machinery, Vacuum Calibration Tank, Parallel Twin Screw

fine cleaner

Get Price Quote

fine cleaner, Atta Chakki, seed processing machinery, Rice Whitener

precision engineered textile processing machines

Get Price Quote

precision engineered textile processing machines

scrap processing machine

Get Price Quote

scrap processing machine, value engineering services, Pet Recycling Plant

Food Processing Machines

Get Price Quote

Food Processing Machines

Food Processing Machine

Get Price Quote

Food Processing Machine, l sealer machine, L-Sealer Machine

Food Processing Machines

Get Price Quote

Food Processing Machines, Oil Cleaning System, Lubrication Equipment

Corn Flakes Processing Plant

Get Price Quote

Corn Flakes Processing Plant, Air Classifiers, Guar Gum Powder machinery

Food Processing Machines

Get Price Quote

Food Processing Machines, pouch packing machine, industrial electric ovens

Food Processing Machine

Get Price Quote

Food Processing Machine, Pouch Packaging Machine